Preparation method of high-purity phenoxyethanol

A technology of pure phenoxyethanol and phenoxyethanol, which is applied in the field of medicine and chemical industry, can solve the problems of high equipment requirements, high production costs, and high energy consumption, and achieve the effects of low equipment requirements, no need for pressure-resistant equipment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment one high-purity phenoxyethanol:

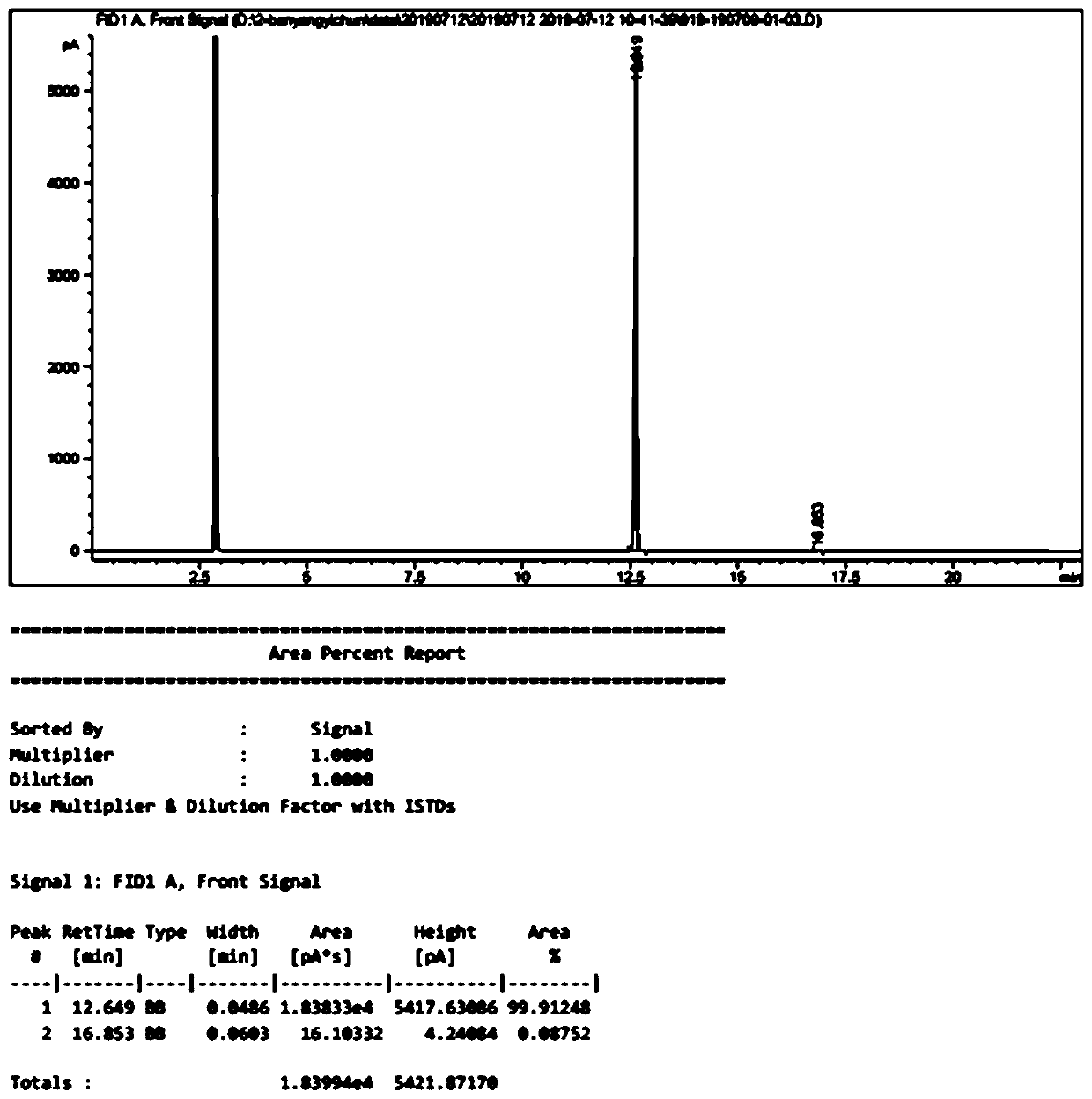

[0021] In a 250ml reaction bottle with a magnet, add 10.0g of industrial phenoxyethanol, 90ml of n-hexane, and 10ml of ethyl acetate, stir to dissolve, add 30ml of 5% aqueous sodium hydroxide solution, stir at room temperature for 0.5-1h, pour the solution Put into a separatory funnel and let stand to separate the liquid. Stir and lower the temperature of the organic layer to -20~-15°C, keep stirring and crystallize for more than 4 hours. Filter, rinse the filter cake with ice n-hexane, and dry to obtain 8.8 g of high-purity phenoxyethanol, with a yield of 88.0%, a GC purity of 99.91%, and a maximum of 0.09% of impurities, such as figure 1 shown.

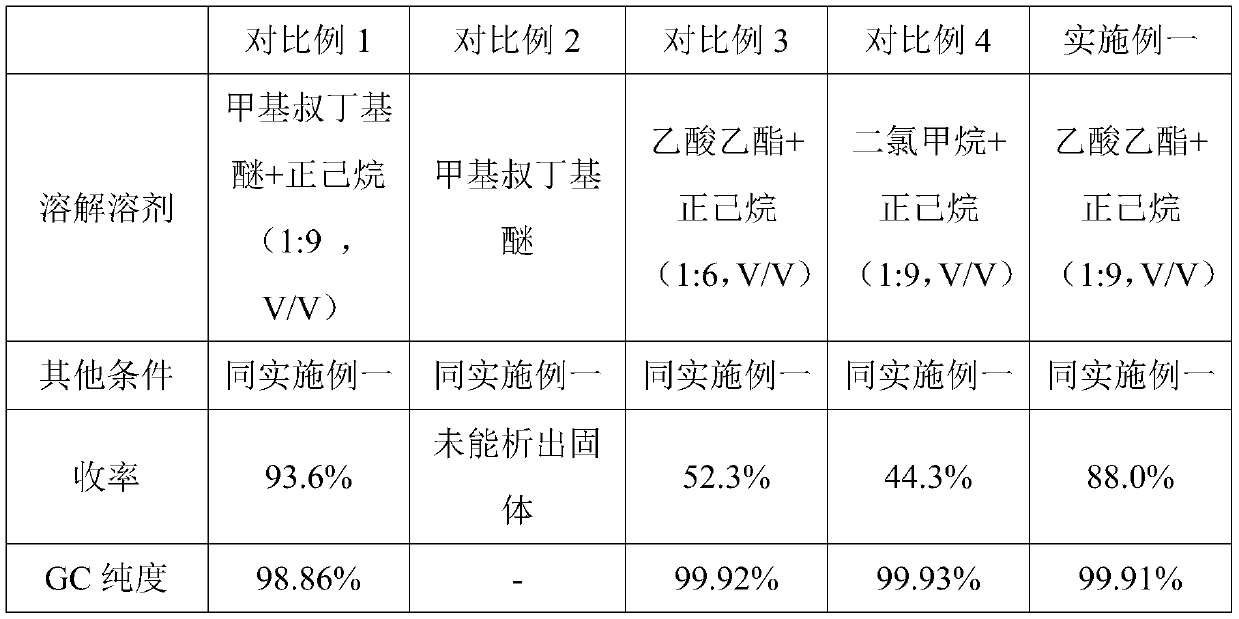

[0022] With reference to the method of Example 1, the effects of different dissolving solvents or proportions on the product yield and purity were compared and investigated at the same time. Table 1 shows the data comparison results of Comparative Examples 1-4 ...

Embodiment 2

[0038] The preparation of embodiment two high-purity phenoxyethanol:

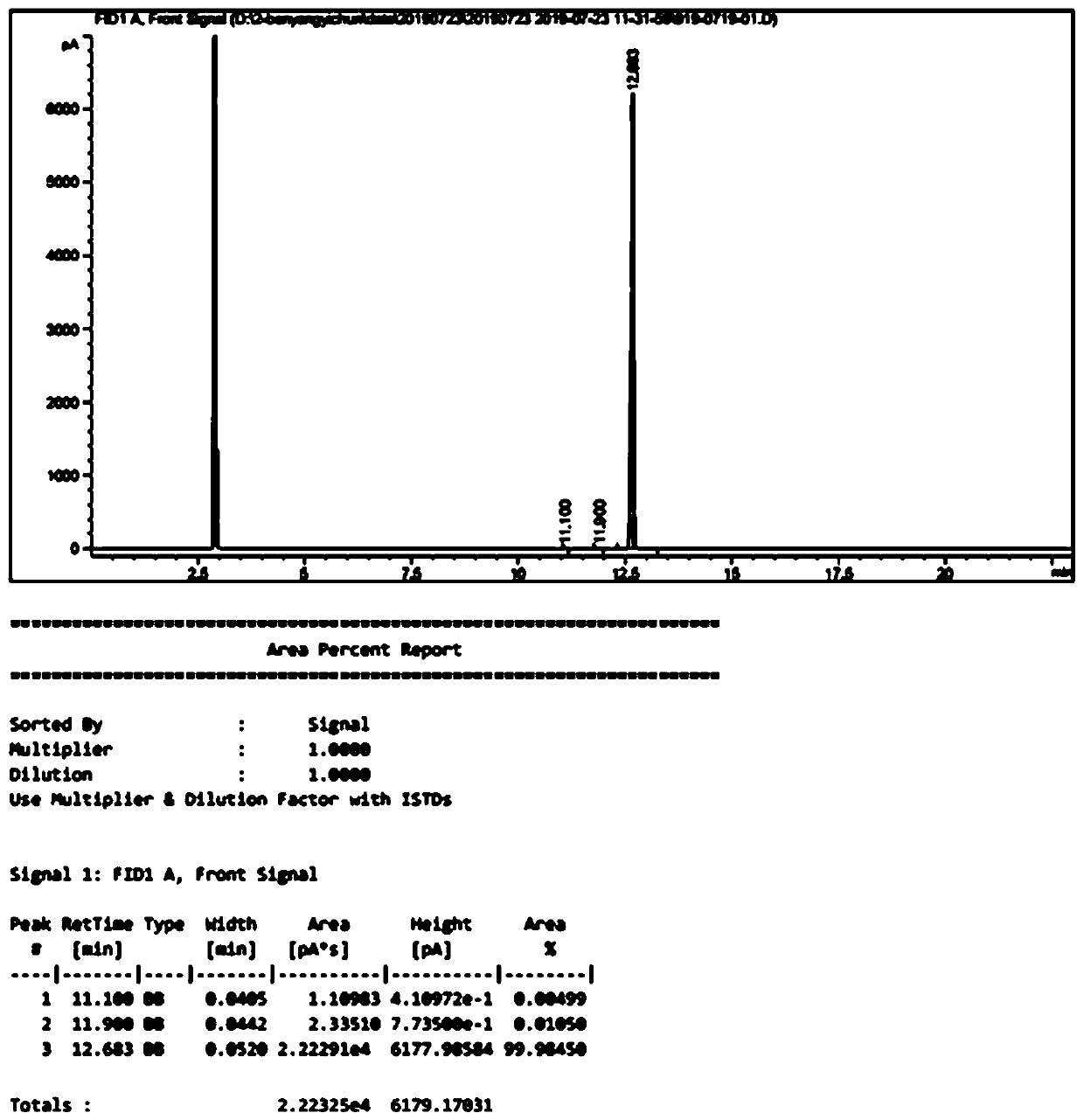

[0039] In a 50L reaction kettle, add 3.0kg of industrial phenoxyethanol, 17.6kg of n-hexane, and 2.7kg of ethyl acetate, stir to dissolve, add 9.0kg of 5% sodium hydroxide aqueous solution, stir at room temperature for 0.5-1h, and let stand to separate the liquid . The organic layer was cooled down to -15~-20°C under stirring, and kept stirring for more than 4 hours for crystallization. Filter, rinse the filter cake with ice n-hexane, and dry to obtain 2.65kg of high-purity phenoxyethanol, with a yield of 88.3%, a GC purity of 99.98%, and a maximum of 0.01% of impurities, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com