Continuous preparation process of dimethyl succinylo succinate

A technology of dimethyl succinyl succinate and dimethyl succinate, which is applied in the field of continuous preparation process of dimethyl succinyl succinate, can solve the problem of precise sodium methoxide drop rate and reaction temperature. Control, large consumption of dimethyl succinate, high production cost, etc., achieve automatic control and continuous production, reduce raw material consumption, and reduce input ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

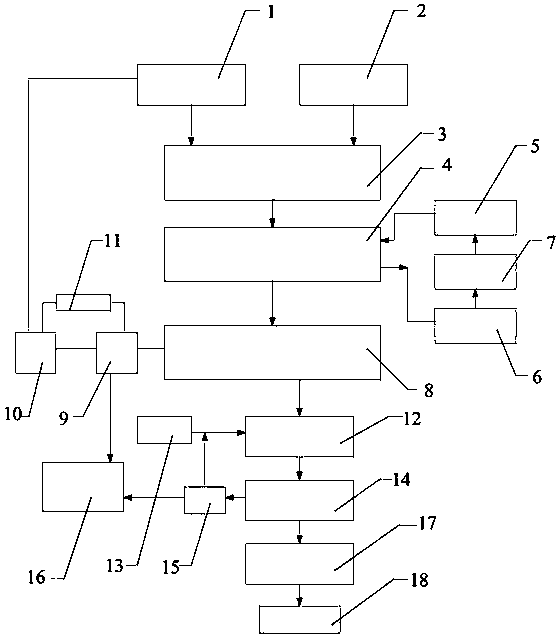

[0015] Refer to attached figure 1 , The present invention provides a continuous preparation process for dimethyl succinyl succinate, comprising a dimethyl succinate metering continuous feeding module 1, a sodium methylate metering continuous feeding module 2, a condensation module 3, an acidification module 4, Strong acid metering continuous feeding module 5, PH online monitoring module 6, control system 7, plate frame module 8, filtrate layering module 9, first rectification module 10, reflux channel 11, refining module 12, methanol metering continuous feeding module 13. Filtration module 14, second rectification module 15, waste water recovery module 16, drying module 17, according to the process flow direction, the dimethyl succinate me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com