Modified flame-retardant ABS material and preparation method thereof

An ABS material and modification technology, which is applied in the field of expanded vermiculite powder modified flame retardant ABS material and its preparation, can solve the problem of high temperature expansion treatment of vermiculite powder, high content of flame retardant added, high water content between layers, etc. Problems, to achieve the effect of good gloss and heat resistance, excellent flame retardant performance, high material gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

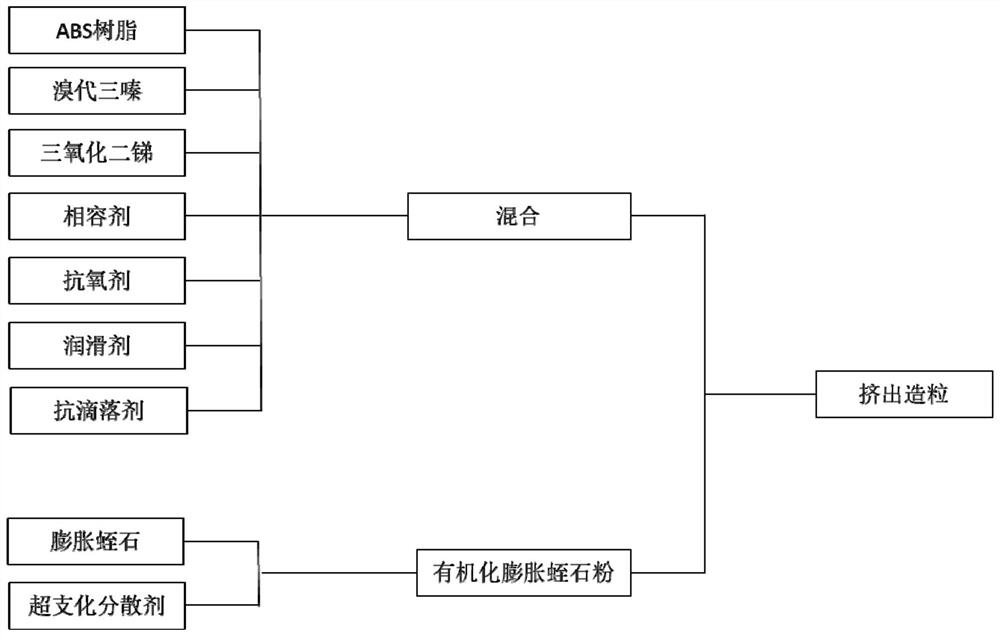

Method used

Image

Examples

preparation example Construction

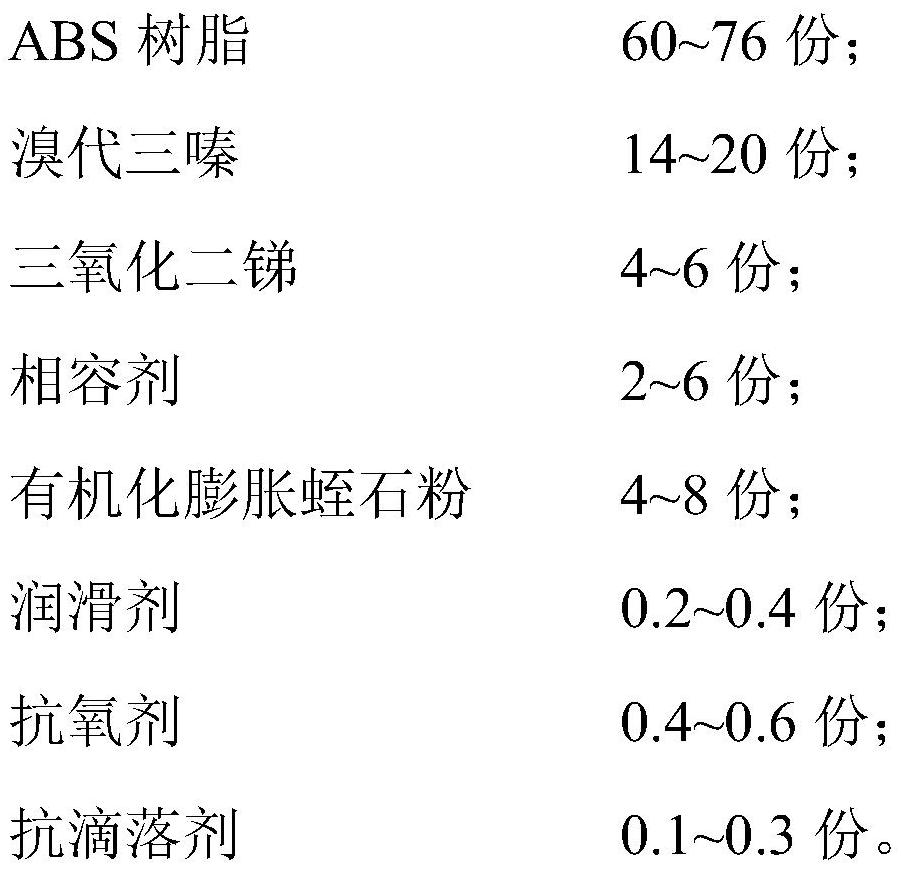

[0055] ABS resin: selected from Ningbo Lejin Yongxing Chemical Co., Ltd.

Embodiment 1

[0065]

[0069] (3) The uniformly mixed raw materials in the step (2) are put into the twin-screw extruder, and granulated after being melted and extruded. That

[0070] The shape of the screw of the parallel twin-screw extruder is a double thread, and the ratio L / D of the screw length L and the diameter D is 35.

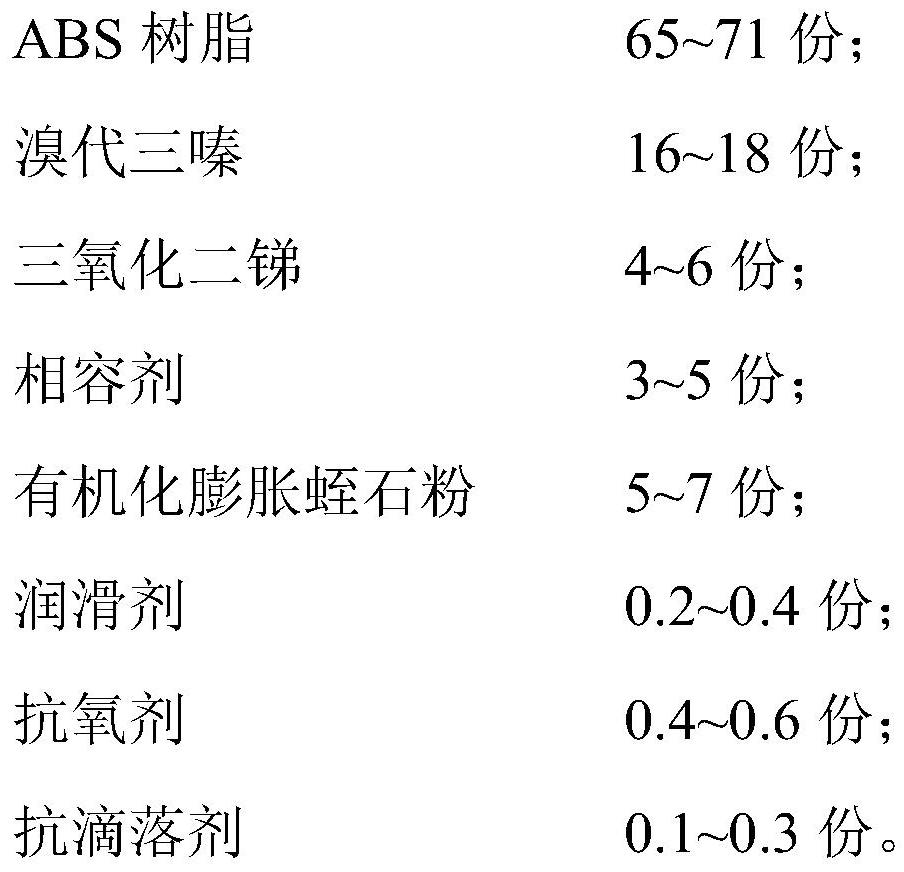

Embodiment 2

[0073]

[0077] (3) The uniformly mixed raw material in the step (2) is put into the twin-screw extruder, and granulated after being melted and extruded. That

[0078] The shape of the screw of the parallel twin-screw extruder is a double thread, and the ratio L / D of the screw length L and the diameter D is 40.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com