Low-temperature test temperature control system and method for aero-engine nozzle oil source pump

An aero-engine and low-temperature test technology, which is applied in machine/engine, control/regulation system, pump test, etc., can solve the problems of large volume of high-power compressor unit, difficulty in balancing the calorific value of the test piece, test accuracy and process influence, etc. , to achieve the effects of easy adaptability, small footprint, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

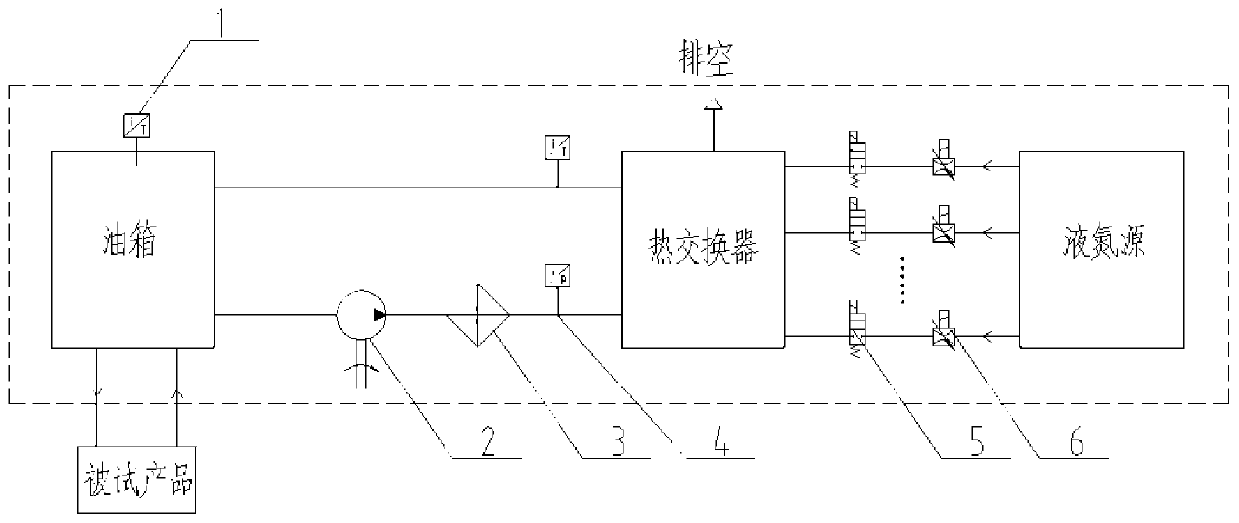

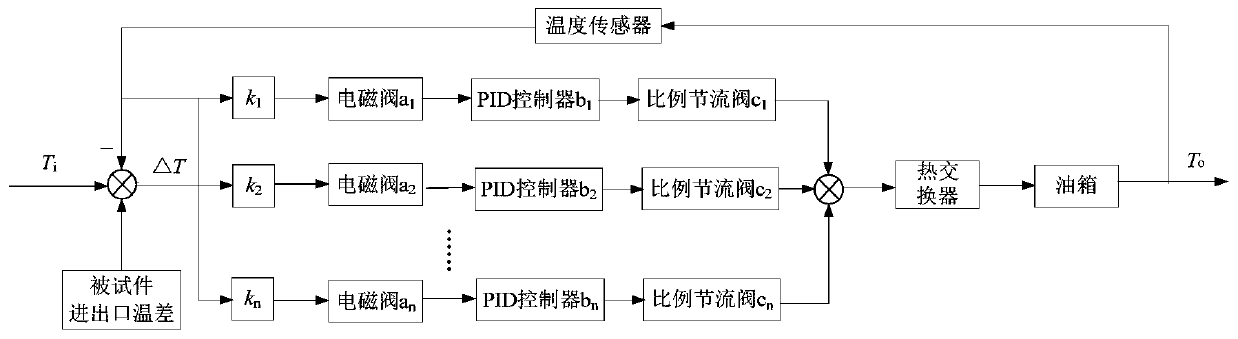

[0020] see figure 1 , as can be seen from the hydraulic schematic diagram of the temperature control system, the temperature control system includes a temperature sensor 1, a circulating hydraulic pump 2, a heater 3, a pressure sensor 4, an electromagnetic switch valve 5, a proportional throttle valve 6, an oil tank, a heat exchange device and liquid nitrogen source. During the low temperature test of the nozzle fuel source pump of the aero-engine, the temperature control system controls the temperature of the test fuel in the fuel tank in real time to balance the heat generated by the tested product during the test.

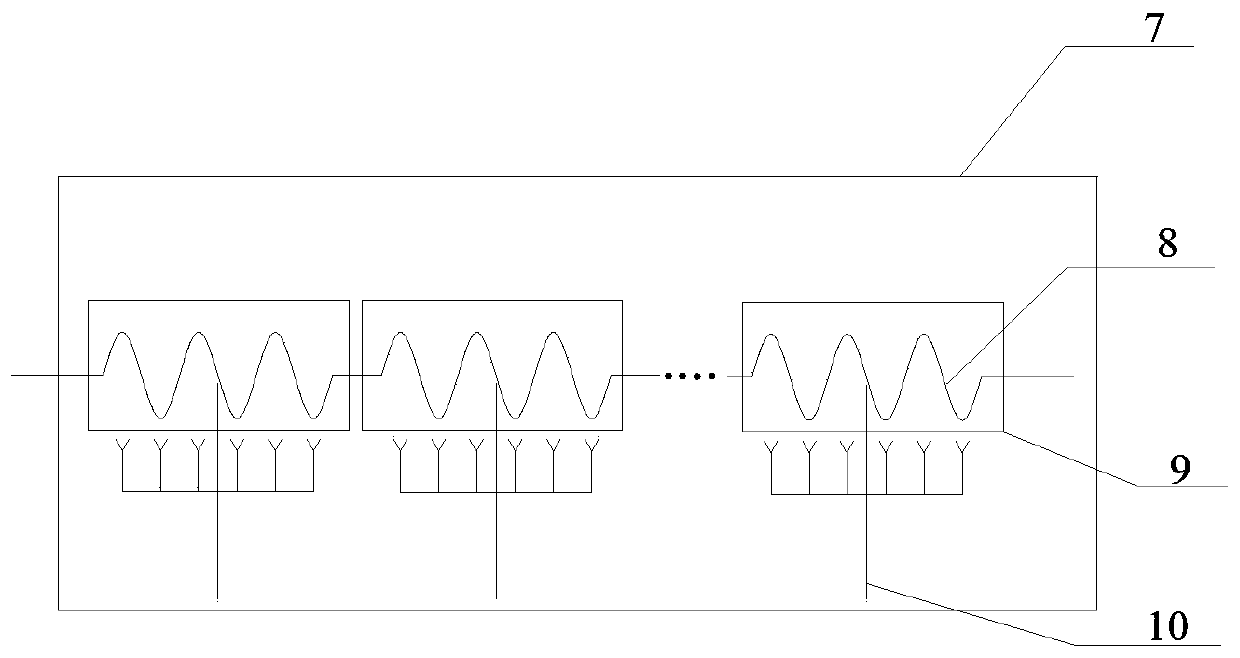

[0021] The fuel circulation system is composed of circulating hydraulic pump 2, heater 3, fuel tank, heat exchanger and hydraulic pipeline, which continuously circulates the fuel in the fuel tank; heat exchanger, liquid nitrogen source, electromagnetic switch valve 5, proportional throttle valve 6 and The liquid nitrogen spray pipeline constitutes a refrigerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com