Preparation method of salt-resistant stable thickener material

A stable, thickener technology, applied in food science and other directions, can solve problems such as poor salt tolerance, and achieve the effect of strong temperature damage, high hydrodynamic volume, and high water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

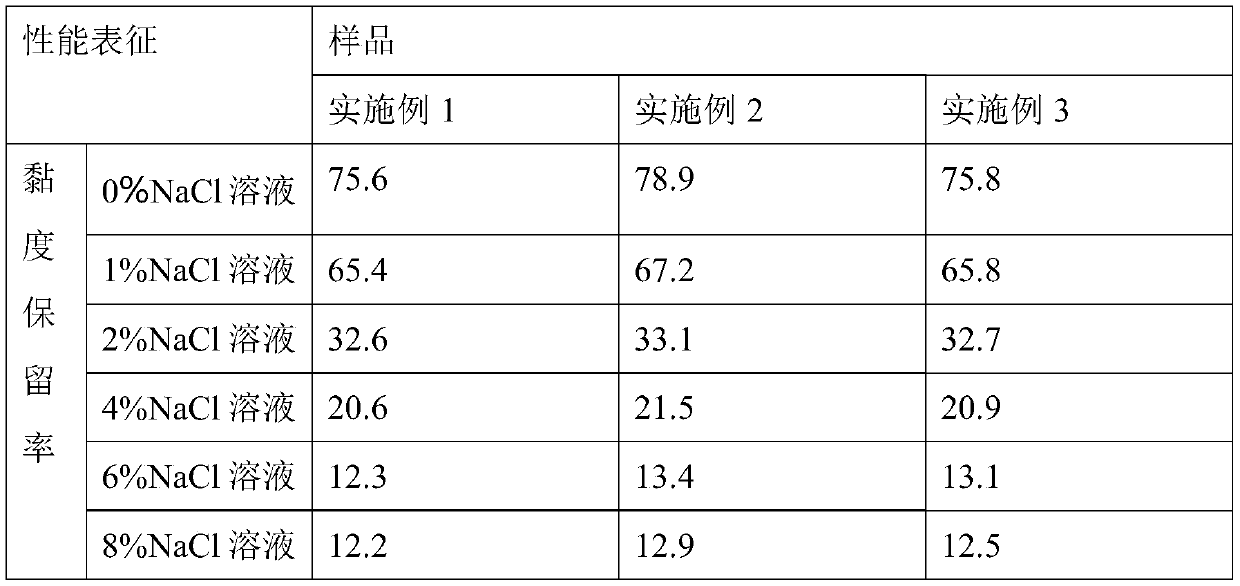

Embodiment 1

[0022] Mix glycine and alanine at a molar ratio of 1:2 to obtain mixed amino acids, and then weigh 45 parts of deionized water, 15 parts of acetone, 10 parts of mixed amino acids, and 1 part of sodium hydroxide in parts by weight. In a four-neck flask, stir and mix and let it stand for 25 minutes to obtain a mixed solution and add the acid chloride dropwise to the mixed solution at a mass ratio of 1:15, maintain the pH to 10.0 with 0.5mol / L sodium hydroxide solution, and wait for the acid chloride to drop After the addition is complete, stir and mix and let stand at room temperature for 10 minutes to obtain a standing solution and add 1.0 mol / L hydrochloric acid dropwise until the pH of the standing solution reaches 2.0, collect the acidified solution and wash it with water for 6 to 8 times, then filter with suction The filter cake was collected, vacuum freeze-dried and ground, passed through a 1000-mesh sieve to obtain modified particles; according to the mass ratio of 1:7, hy...

Embodiment 2

[0024]Mix glycine and alanine at a molar ratio of 1:2 to obtain mixed amino acids, and weigh 47 parts of deionized water, 17 parts of acetone, 12 parts of mixed amino acids, and 1 part of sodium hydroxide in parts by weight. In a four-necked flask, stir and mix and let it stand for 27 minutes to obtain a mixed solution and add acid chloride dropwise to the mixed solution at a mass ratio of 1:15, maintain the pH to 10.0 with 0.5mol / L sodium hydroxide solution, wait for the acid chloride to drop After the addition is complete, stir and mix and let stand at room temperature for 12 minutes to obtain a standing solution and add 1.0 mol / L hydrochloric acid dropwise until the pH of the standing solution reaches 2.0, collect the acidified solution and wash it with water for 7 times, then suction filter and collect The filter cake was vacuum freeze-dried and ground, and passed through a 1000-mesh sieve to obtain modified particles; according to the mass ratio of 1:7, hydroquinone was ad...

Embodiment 3

[0026] Glycine and alanine were mixed at a molar ratio of 1:2 to obtain mixed amino acids, and then weighed in parts by weight 50 parts of deionized water, 20 parts of acetone, 15 parts of mixed amino acids, and 2 parts of sodium hydroxide. In a four-necked flask, stir and mix and let it stand for 30 minutes to obtain a mixed solution and add acid chloride dropwise to the mixed solution at a mass ratio of 1:15, maintain the pH to 10.0 with 0.5mol / L sodium hydroxide solution, wait for the acid chloride to drop After the addition, stir and mix and let stand at room temperature for 15 minutes to obtain a standing solution and add 1.0 mol / L hydrochloric acid dropwise until the pH of the standing solution reaches 2.0, collect the acidified solution and wash it with water for 8 times, then suction filter and collect The filter cake was vacuum freeze-dried and ground, and passed through a 1000-mesh sieve to obtain modified particles; according to the mass ratio of 1:7, hydroquinone wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com