Structural flexible electronic skin

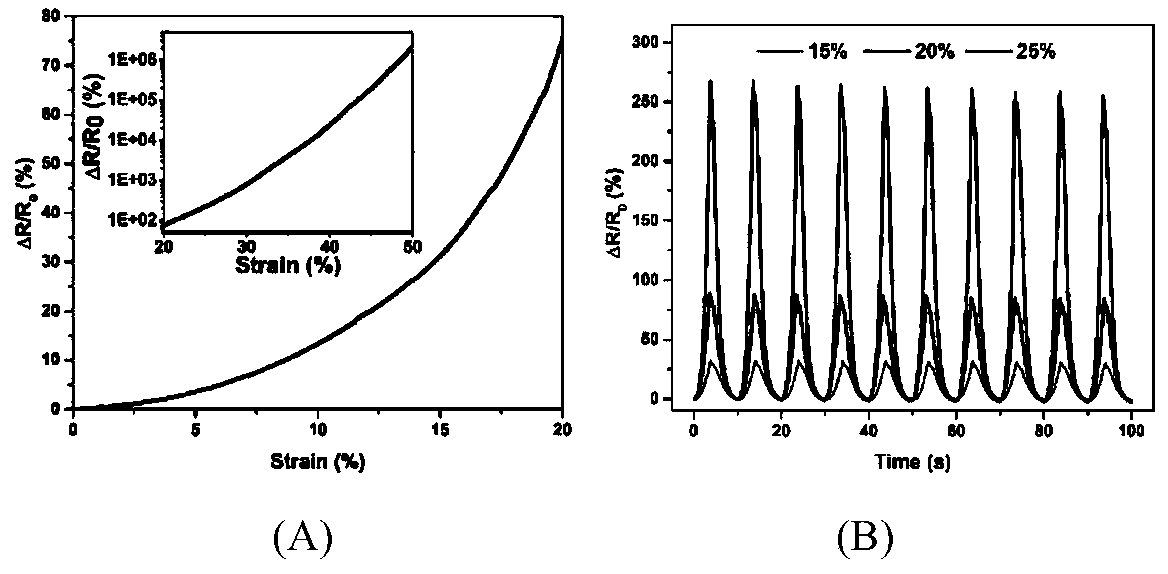

An electronic skin and structural technology, applied in the field of flexible sensors, can solve the problems of complex preparation process and inability to truly simulate the mechanical properties of human skin, and achieve the effects of high tactile sensitivity, large stretchable strain, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

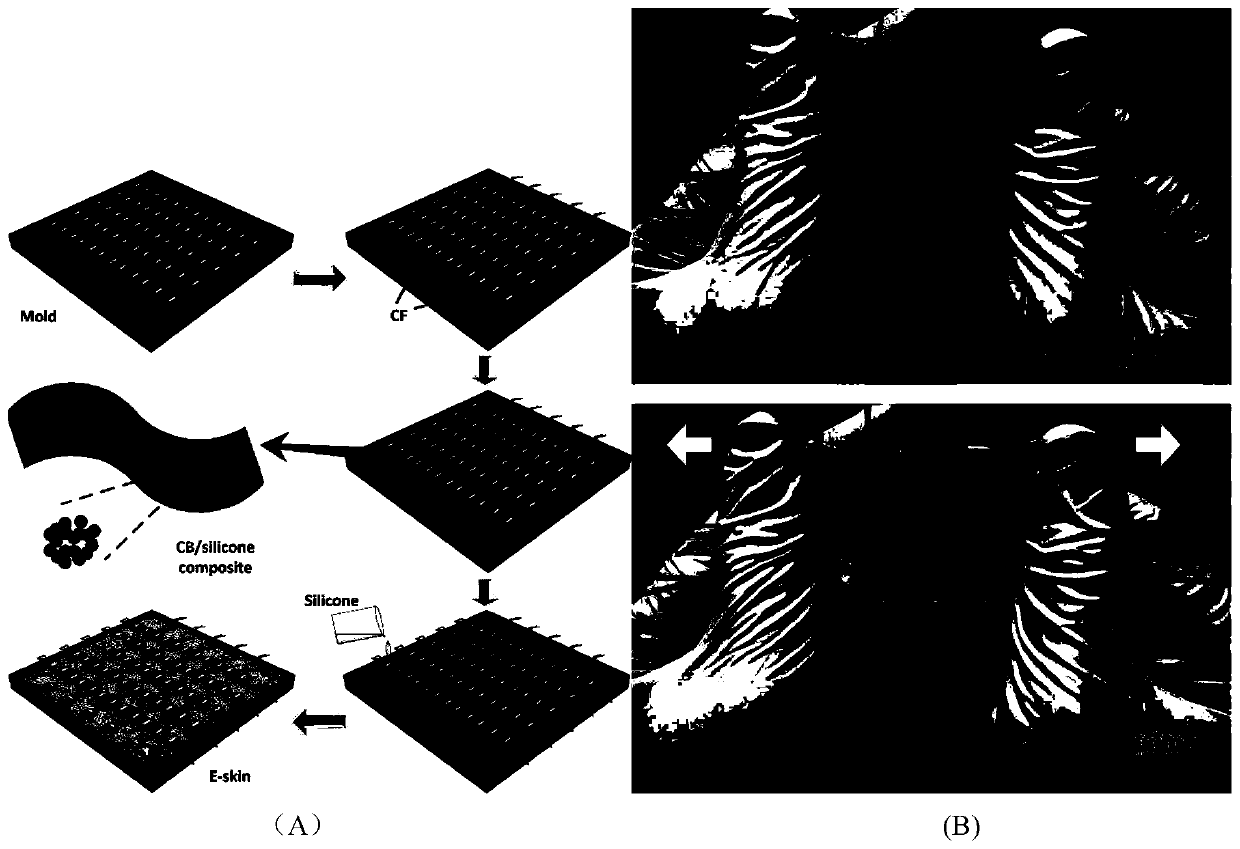

[0025] ① Mix carbon black and polydimethylsiloxane evenly, pour into a mold for curing, and obtain a flexible composite material sheet with a thickness of 2mm.

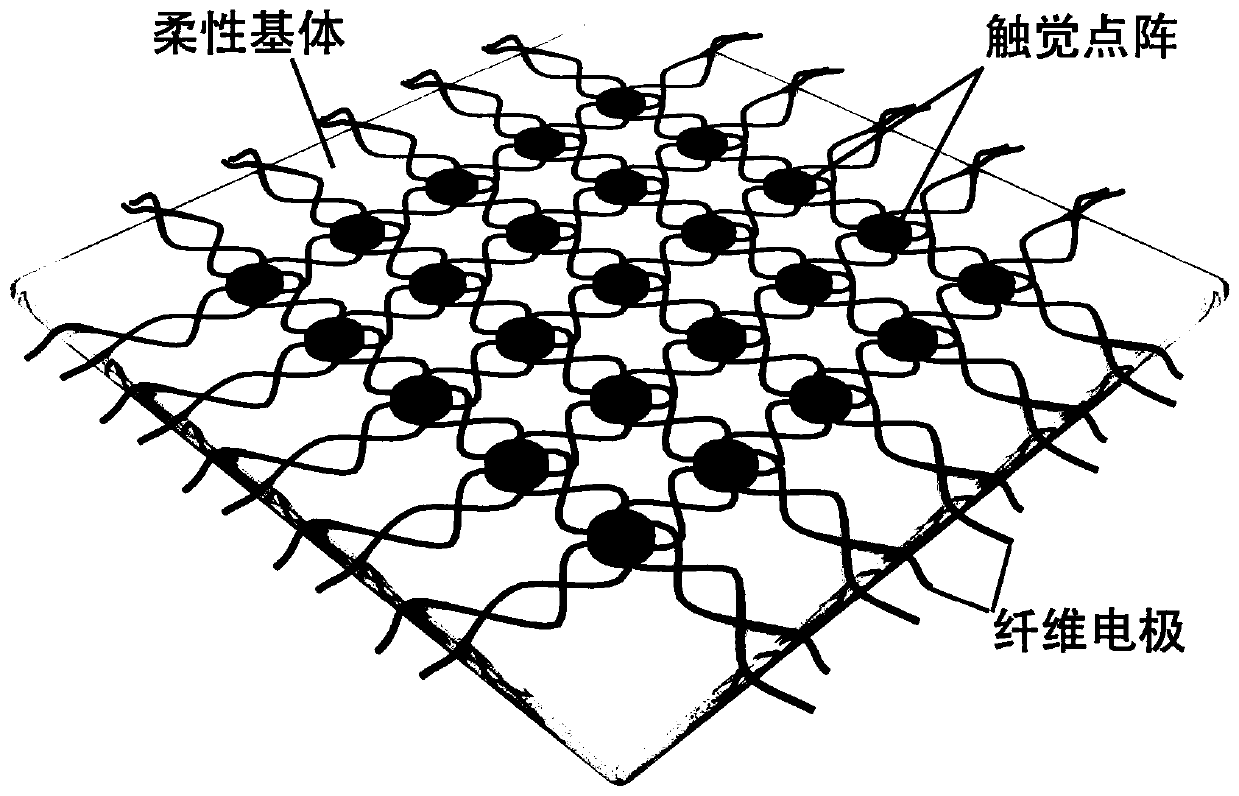

[0026] ② Prepare as figure 2 (A) In the mold shown in (A), two bundles of carbon fibers are cross-wound on the bottom of the short column in the mold to form a quasi-sinusoidal structure. The volume content of the electrode array accounts for 0.52% of the electronic skin.

[0027] ③Cut the composite sheet obtained in step ① into a cylindrical tactile unit of φ5*2mm, such as figure 2 As shown in (A), the tactile units are arranged in the mold, and the arrangement density of the tactile units is 1 / cm -2 ; Cross-wind the carbon fiber electrodes on top of the haptic unit in the same way along the direction perpendicular to the carbon fiber winding at the bottom of the mold stub.

[0028] ④ Use the piezoresistive composite material mixture (before curing) configured in ① as an adhesive, coat the upper and lower surfac...

Embodiment 2

[0033] ① Mix carbon nanotubes and polydiethylsiloxane evenly, pour them into a mold for curing, and obtain a flexible composite material sheet with a thickness of 4 mm.

[0034] ②The copper wire electrodes are cross-wound at the bottom of the mold to form a zigzag structure. The buckling degree of the fiber electrode array (the ratio of the length of the zigzag structure after straightening to that before unstretching) is 1.8, and the volume content of the fiber electrode array in the electronic skin is 0.6%.

[0035] ③Cut the composite sheet obtained in step ① into cylindrical tactile units of φ3*4mm, arrange the tactile units in the mold, and the arrangement density of the tactile units is 3 pieces / cm -2 ; Along the direction perpendicular to the winding of the copper wire at the bottom of the mold stub, cross-wind the copper wire electrode on the top of the haptic unit in the same manner.

[0036] ④ Use the piezoresistive composite material mixture (before curing) configur...

Embodiment 3

[0040] ① Evenly mix graphene and polymethylvinyl siloxane, pour it into a mold for curing, and obtain a 10mm thick flexible composite material sheet.

[0041] ②The silver wire electrodes are cross-wound at the bottom of the mold to form an "S"-shaped structure. The degree of buckling of the fiber electrode array (the ratio of the length of the "S"-shaped structure after straightening to that before unstraightening) is 2.4. The volume content is 0.23%.

[0042] ③Cut the composite sheet obtained in step ① into cylindrical tactile units of φ15*10mm, arrange the tactile units in the mold, and the arrangement density of the tactile units is 0.5 pieces / cm - 2 ; Along the direction perpendicular to the winding of the silver wire at the bottom of the short column of the mold, cross-wind the silver wire electrode on the top of the haptic unit in the same way.

[0043] ④ Use the piezoresistive composite material mixture (before curing) configured in ① as an adhesive, coat the upper an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com