Frozen ground region negative-temperature well cementation cement slurry, preparation method and applications thereof

A warm-solidification technology in permafrost regions, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as inability to carry out cementing operations, poor cementing quality, and uncured cement, and increase the hydration rate , increase the solid phase ratio of the slurry, and promote the effect of continuous generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

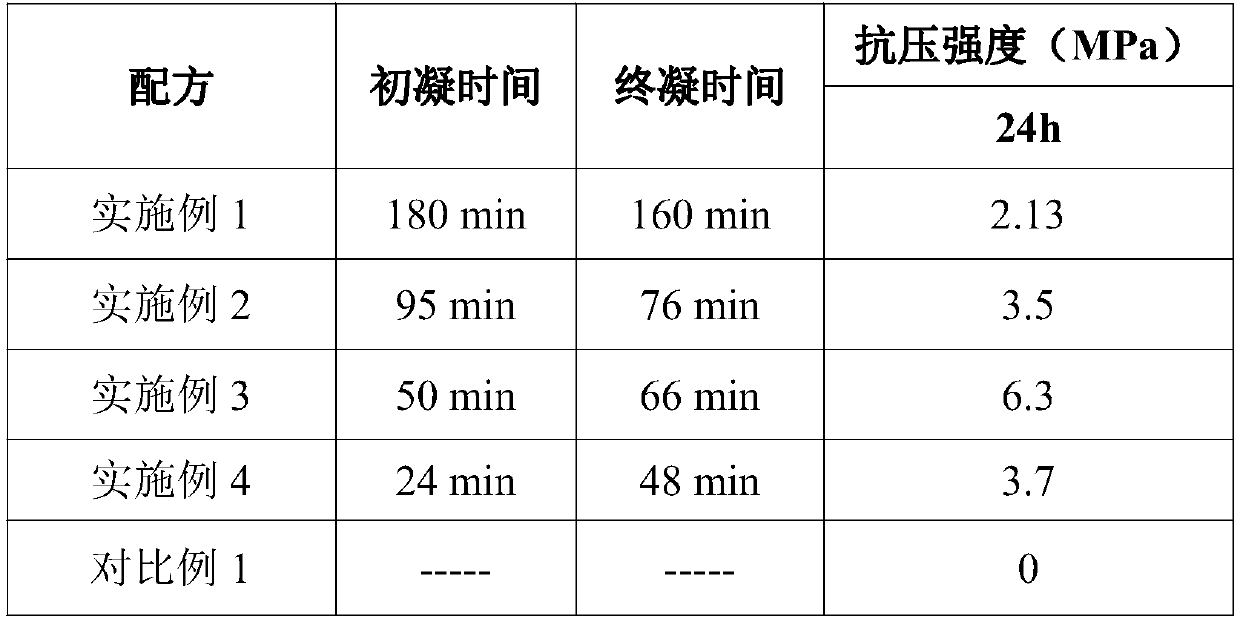

Examples

Embodiment 1

[0069] Dissolve 6 parts of negative temperature antifreeze and early strength agent in 44 parts of water to form a paste solution and place it in the freezer until the temperature of the solution drops to -18°C. Pour the slurry preparation solution at -18°C into the slurry cup, start the agitator to stir at a low speed, and quickly add 100 parts of modified aluminate cement weighed in proportion, 0.05 parts of alcohol ammonia coagulant, and 2 parts of light metal expansion agent , 3 parts of non-ionic polymer fluid loss reducer, and high-speed stirring for 1 min to obtain the negative temperature cementing cement slurry in the permafrost region.

Embodiment 2

[0071] Dissolve 9 parts of negative temperature antifreeze and early strength agent in 44 parts of water to form a slurry preparation solution and place it in the freezer until the temperature of the solution drops to -18°C. Pour the slurry preparation solution at -18°C into the slurry cup, start the agitator to stir at low speed, and quickly add 100 parts of modified aluminate cement weighed in proportion, 0.5 parts of alcohol ammonia coagulant, and 2 parts of light metal expansion agent , 3 parts of non-ionic polymer fluid loss reducer, and high-speed stirring for 1 min to obtain the negative temperature cementing cement slurry in the permafrost region.

Embodiment 3

[0073]Dissolve 10 parts of negative temperature antifreeze and early strength agent in 44 parts of water to form a slurry preparation solution and place it in the freezer until the temperature of the solution drops to -18°C. Pour the slurry preparation solution at -18°C into the slurry cup, start the agitator to stir at low speed, and quickly add 100 parts of modified aluminate cement weighed in proportion, 1 part of alcohol ammonia coagulant, and 2 parts of light metal expansion agent , 3 parts of non-ionic polymer fluid loss reducer, and high-speed stirring for 1 min to obtain the negative temperature cementing cement slurry in the permafrost region.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com