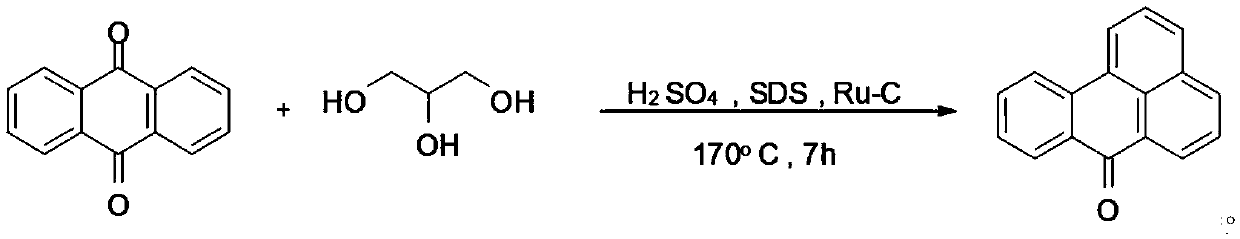

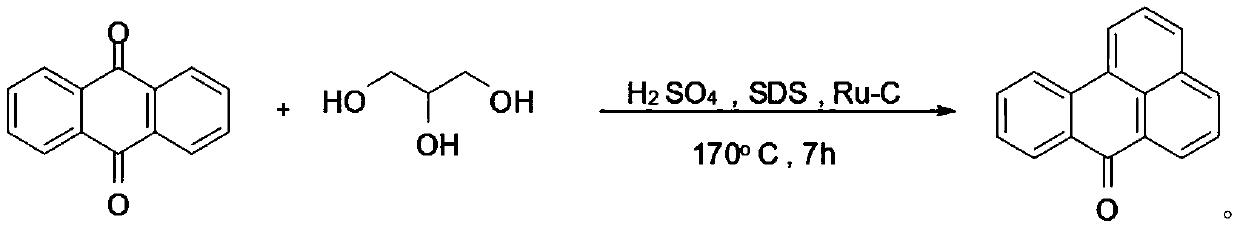

Novel production method of benzanthrone

A technology of benzoanthrone and its production method, which is applied in the field of fine chemicals, can solve the problems such as difficult recycling of raw materials and reaction by-products, and achieve the effects of low cost, easy process control, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

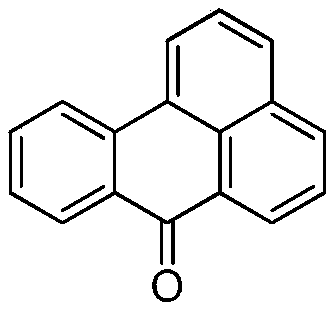

Image

Examples

Embodiment 1

[0032] Prepare anthraquinone 21kg (molecular weight 208.2, 101mol), ruthenium carbon (containing 5% palladium carbon) 0.26kg, 60% sulfuric acid 0.08kg, phase transfer catalyst sodium lauryl sulfate 210g, chlorobenzene 100kg, put the above-mentioned substances into 600L In a pressure reactor with a capacity of 2 At the same time, make the pressure in the container reach 1400kPa, stir at 175°C for 6.5h; cool the reaction solution to 110°C, and discharge the remaining H 2 Finally, filter the reaction solution, then wash in batches with 30L chlorobenzene, and the filter cake is used as the next batch of catalyst recycling;

[0033] Then the above-mentioned chlorobenzene residue and washing liquid are poured into a 500L clean reactor, and then 20.6kg (molecular weight 92.1, 200mol) of glycerine (glycerine) (glycerine) with a concentration of 85% is added, and heated to 105 while stirring. ℃;

[0034] Control the reaction temperature at 105-120°C and add 35.8kg of sulfuric acid (m...

Embodiment 2

[0037] Prepare anthraquinone 21kg (molecular weight 208.2, 101mol), ruthenium carbon 0.10kg, 60% sulfuric acid 0.04kg, phase transfer catalyst sodium lauryl sulfate 105g, chlorobenzene 65kg, put the above-mentioned material in the pressure reactor of 400L capacity, In access to H 2 At the same time, make the pressure in the container reach 1200kPa, stir at 180°C for 6h; cool the reaction solution to 110°C, and discharge the remaining H 2 Finally, filter the reaction solution, then wash in batches with 30L chlorobenzene, and the filter cake is used as the next batch of catalyst recycling;

[0038] Then, pour the above-mentioned chlorobenzene residue and washing liquid into a 500L clean reactor, then add 15.4kg of glycerol (molecular weight: 92.1, 150mol) with a concentration of 85%, and heat to 110°C while stirring;

[0039] Control the reaction temperature at 100-120°C and add 21.9kg of sulfuric acid (molecular weight: 98, 200mol) with a concentration of 85% dropwise. After t...

Embodiment 3

[0041]Prepare anthraquinone 21kg (molecular weight 208.2, 101mol), ruthenium carbon (containing 5% palladium carbon) 0.40kg, 80% sulfuric acid 0.26kg, phase transfer catalyst sodium lauryl sulfate 210g, chlorobenzene 160kg, put the above-mentioned substances into 800L In a pressure reactor with a capacity of 2 At the same time, make the pressure in the container reach 1600kPa, stir at 160°C for 8h; cool the reaction solution to 100°C, and discharge the remaining H 2 Finally, filter the reaction solution, then wash in batches with 30L chlorobenzene, and the filter cake is used as the next batch of catalyst recycling;

[0042] Then, pour the above-mentioned chlorobenzene residue and washing liquid into a 600L clean reactor, and then add 30.8kg (molecular weight 92.1, 300mol) of glycerine (glycerine) with a concentration of 85%, and heat it to 105 while stirring. ℃;

[0043] Control the reaction temperature at 105-120°C and add 54.8kg of sulfuric acid (molecular weight 98,500mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com