Water-soluble cardanol-based aqueous epoxy resin curing agent, preparation method and applications thereof

A water-based epoxy resin, cardanol technology, applied in epoxy resin coatings, chemical instruments and methods, preparation of organic compounds, etc. Good water solubility, good emulsifying and curing properties, low water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

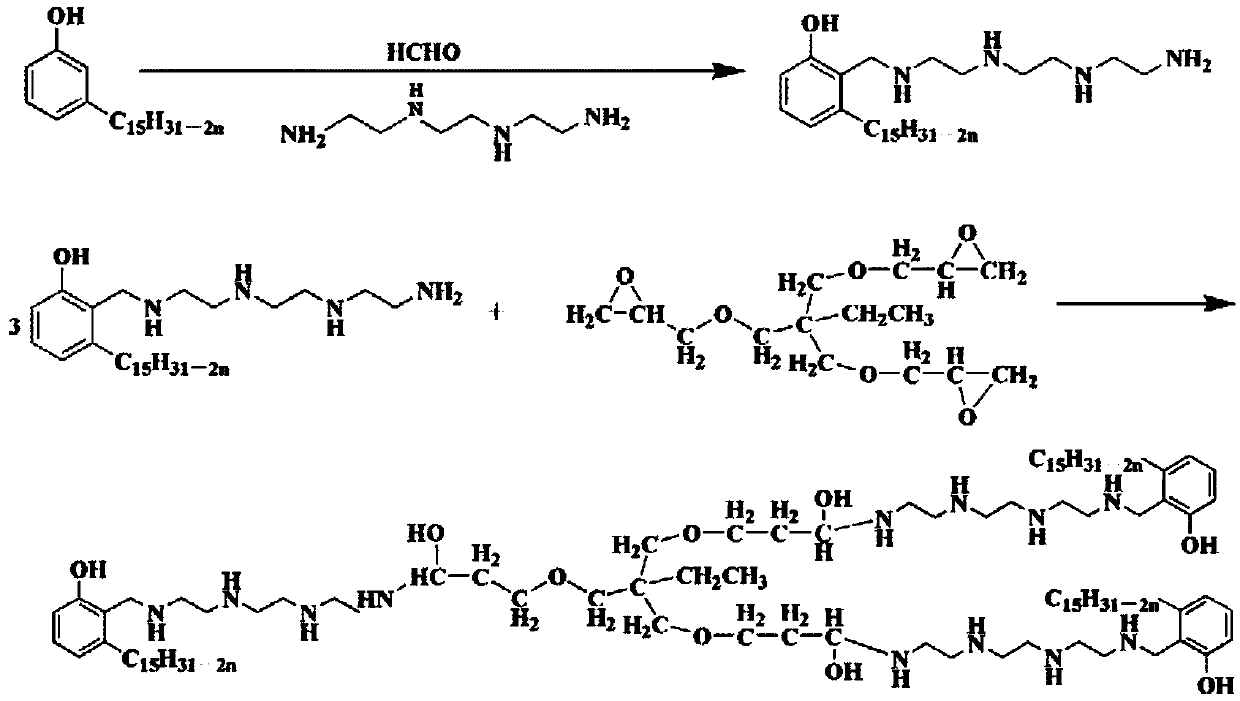

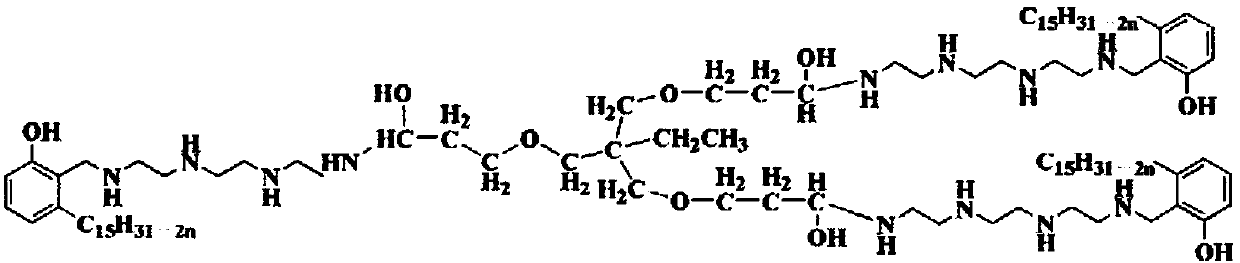

[0029] According to the principle of mannich reaction and ring-opening reaction, another aspect of the embodiments of the present invention provides a method for preparing a water-soluble cardanol-based waterborne epoxy resin curing agent, comprising:

[0030] Making the mixed reaction system comprising at least cardanol, triethylenetetramine and formaldehyde undergo a Mannich (mannich) reaction to obtain an intermediate product;

[0031] And, in a protective atmosphere, the intermediate product is subjected to a ring-opening reaction with trimethylolpropane triglycidyl ether to obtain a water-soluble cardanol-based aqueous epoxy resin curing agent.

[0032] In some embodiments, the molar ratio of cardanol, triethylenetetramine and formaldehyde is 1:(1.0-1.5):1.

[0033] In some embodiments, the temperature of the Mannich reaction is 80-120°C.

[0034] Further, the time of the Mannich reaction is 3-5h.

[0035] In some embodiments, the molar ratio of the intermediate product...

Embodiment 1

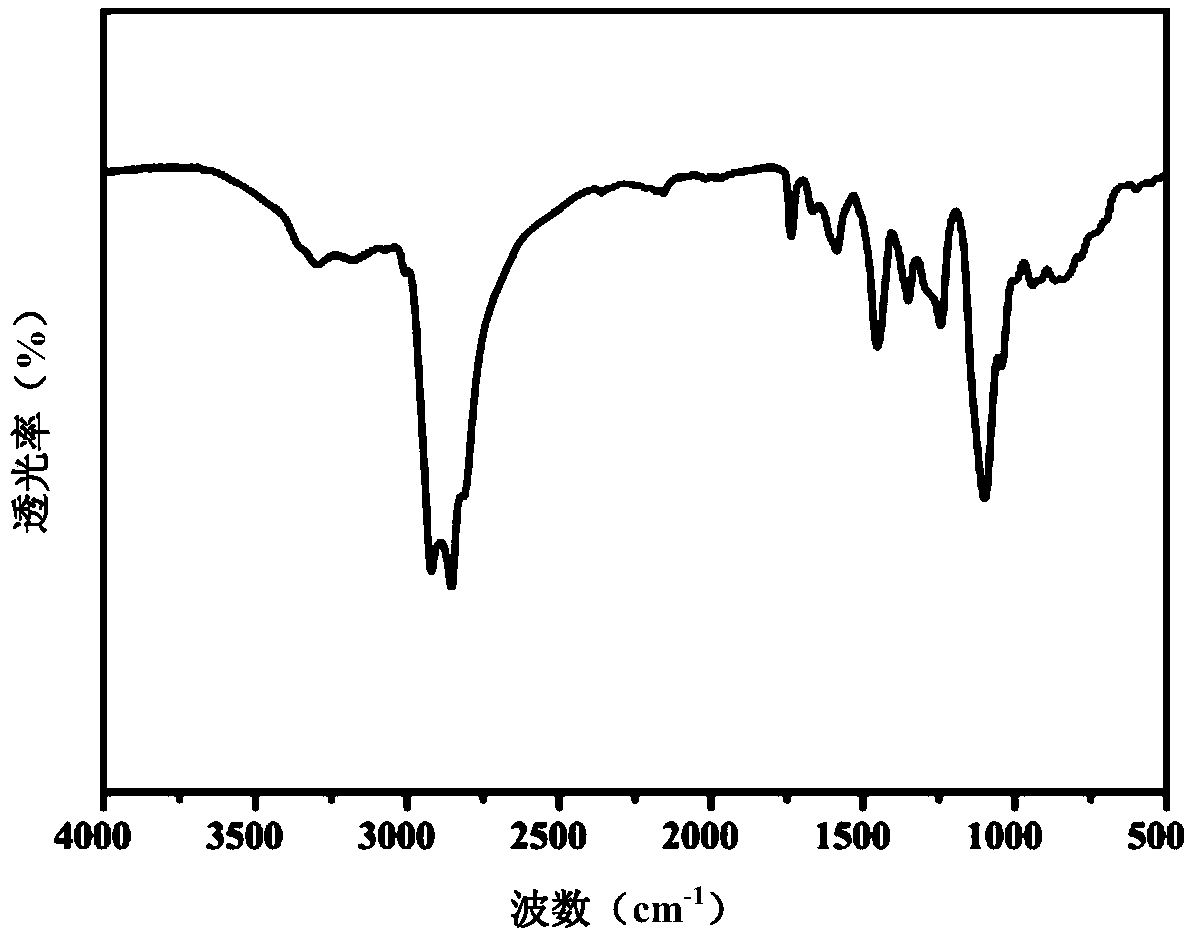

[0054] The first step of the reaction is to add 1.0mol of cardanol and 1.2mol of triethylenetetramine in a three-necked flask equipped with a thermometer, a water separator and a stirring magnet, preheated to 80°C and slowly drop in 1.0mol of 37 % aqueous formaldehyde solution, heated to 100 °C and reacted for 4 h to obtain an intermediate product, which was a reddish-brown viscous liquid. The second step reaction, in the there-necked flask equipped with a stirring magnet, a protective gas conduit, and a thermometer, add 4.0 mol of the intermediate product, stir and heat in an argon atmosphere and be warming up to 60 ° C, and use a separatory funnel at this temperature. Slowly add 1.0 mol of trimethylolpropane triglycidyl ether dropwise, and spin off unreacted triethylene tetramine after the reaction for 3 hours to obtain a reddish-brown viscous liquid, that is, a water-soluble cardanol water-based epoxy resin curing agent, Yield was 92%. The infrared spectrum of the water-so...

Embodiment 2

[0056] In the first step reaction, in a three-necked flask equipped with a thermometer, a water separator and a stirring magnet, add 1.0 mol of cardanol and 1 mol of triethylenetetramine, and slowly drop in 1.0 mol of 37% after preheating to 80 °C The aqueous formaldehyde solution was heated to 100 °C and reacted for 4 h to obtain an intermediate product, which was a reddish-brown viscous liquid. The second step reaction, in the there-necked flask equipped with a stirring magnet, a protective gas conduit, and a thermometer, add 4.0 mol of the intermediate product, stir and heat in an argon atmosphere and be warming up to 60 ° C, and use a separatory funnel at this temperature. Slowly add 1.0 mol of trimethylolpropane triglycidyl ether dropwise, and spin off unreacted triethylene tetramine after the reaction for 3 hours to obtain a reddish-brown viscous liquid, that is, a water-soluble cardanol water-based epoxy resin curing agent, The yield was 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com