Gray heat-reflecting cooling coating, application thereof in asphalt pavements, and preparation method of coating

A heat reflection and coating technology, applied in the direction of reflection/signal coatings, fireproof coatings, polyurea/polyurethane coatings, etc., can solve the problem of not being suitable for asphalt pavement, wear resistance and skid resistance can not meet the actual road use index, construction technology Complicated problems, to improve high temperature thermal stability diseases, alleviate urban heat island effect, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

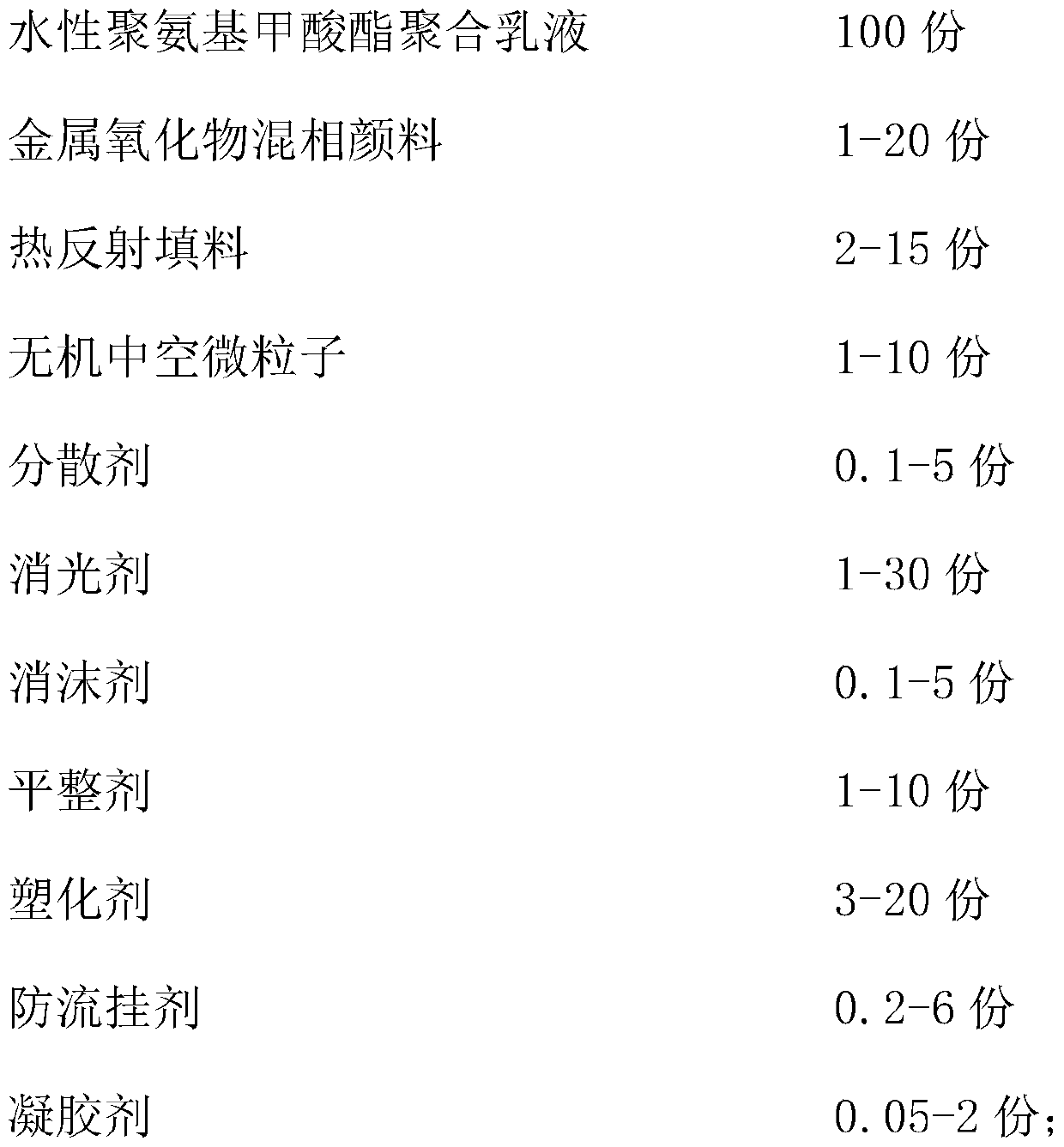

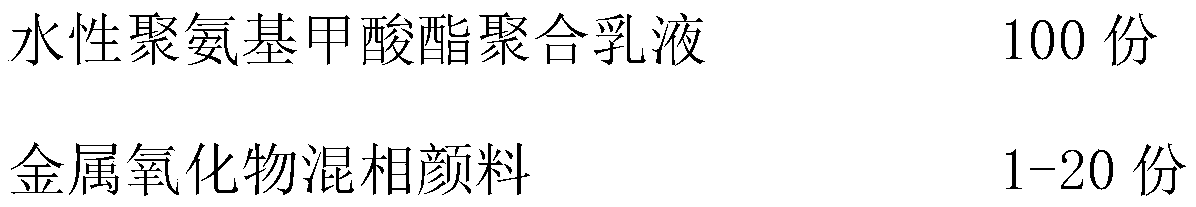

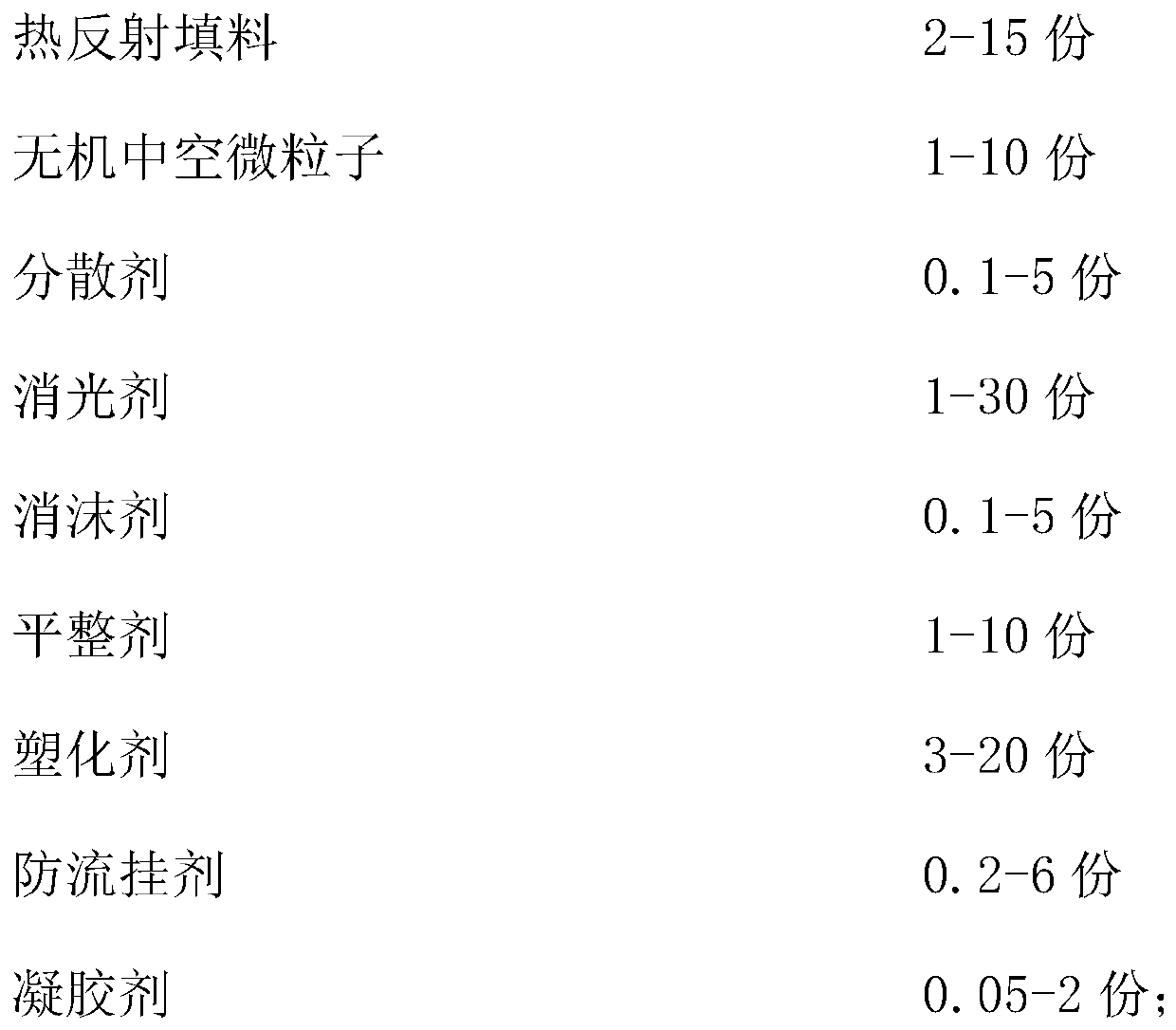

Method used

Image

Examples

Embodiment 1-4

[0040] Embodiment 1-4 is prepared according to the following steps:

[0041] a. Add water-based polyurethane polymer emulsion into the shearing machine, set the rotating speed at 200-300r / min, adjust the pH value of the system to 7-8 with ammonia water, and continue shearing for 5-10min.

[0042] b. Increase the shearing speed to 300-400r / min, add the dispersant and the first part of defoamer and continue shearing for 5-10min.

[0043] c. Mix metal oxide mixed-phase pigments, heat-reflecting fillers, inorganic hollow particles and matting agent thoroughly to obtain a mixture, adjust the speed of the shearing machine to 600-800r / min, then add the above mixture to the emulsion and continue shearing for 10 -30min.

[0044] d. Add the second part of defoamer, leveling agent and plasticizer dropwise into the system and continue shearing for 0.5-1h;

[0045] e. Finally, add the anti-sagging agent and gelling agent dropwise into the system, continue to cut for 0.5-1h, and discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com