Preparation method of p-type and n-type conductive lithium niobate nanowires

A technology of conductive lithium niobate and conductive nanometers, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as limiting the preparation of active devices, and achieve the promotion of development and repeatability High, simple method and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] After many times of research and development, the invention provides a preparation method of p-type and n-type conductive lithium niobate nanowires, which mainly includes the following steps:

[0037] Step 1: heat-treating the multi-domain lithium niobate crystal by using heat-fixing technology. In the heat treatment process, the temperature is raised first, and then kept for a period of time after rising to the specified temperature, and then the temperature is lowered at a certain rate. The protons in the crystal are fixed in the domain wall region through the heat treatment process;

[0038] Step 2: Polarize the lithium niobate crystal prepared above by using the electric polarization technology;

[0039] Step 3: Polarize the above-prepared lithium niobate crystals for the second time by using the electric polarization technique to change the conductivity type of the nanowires prepared in step 2. The preparation method utilizes the theory of proton fixation in lith...

Embodiment 1

[0063] The lithium niobate crystal used in this embodiment is Z tangential doped magnesium 5mol% lithium niobate crystal with the same composition, and the crystal size is: X×Y×Z=8mm×8mm×0.5mm. The lithium niobate crystal has been made into a periodically poled ferroelectric domain structure.

[0064] The specific implementation steps are:

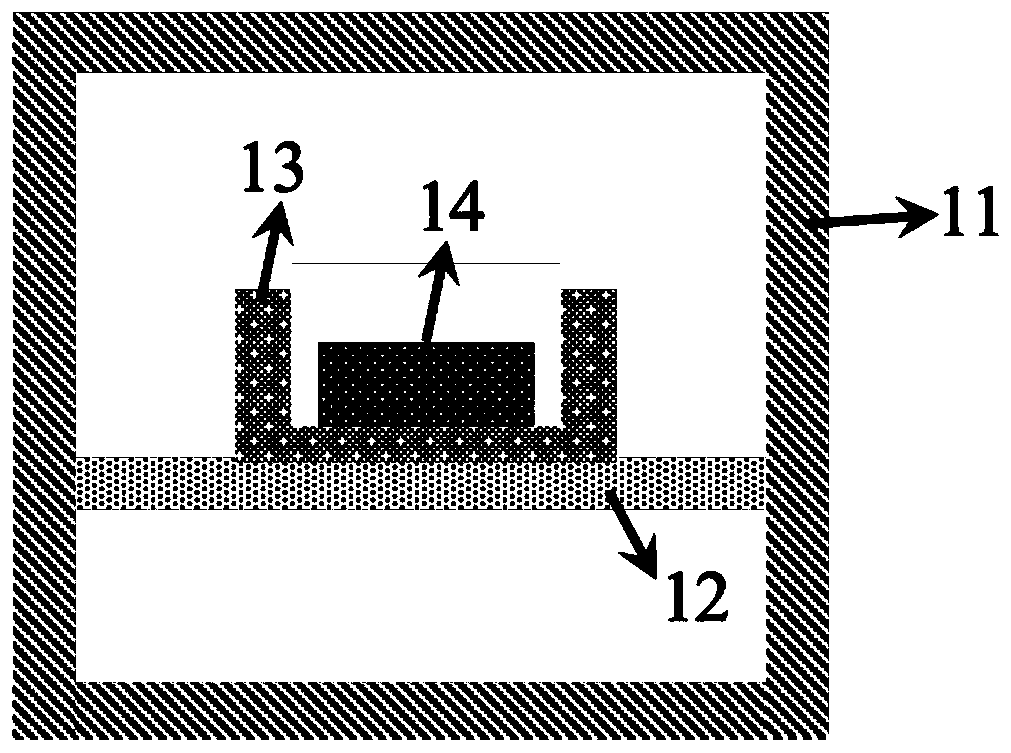

[0065] (1) The periodically poled lithium niobate crystal in this embodiment is placed in a heating furnace for heat treatment. Experimental device such as figure 1 shown. The temperature rising rate is 5°C / min, the holding temperature is 120°C, the holding time is 2h (hour), and the cooling rate is 5°C / min.

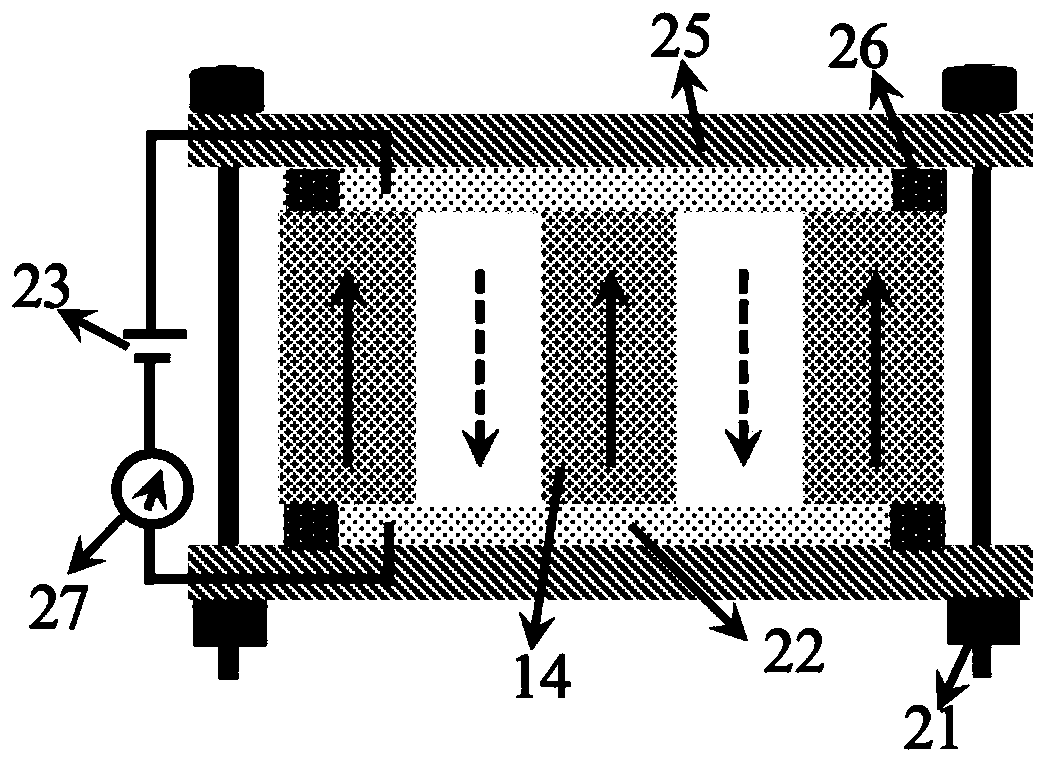

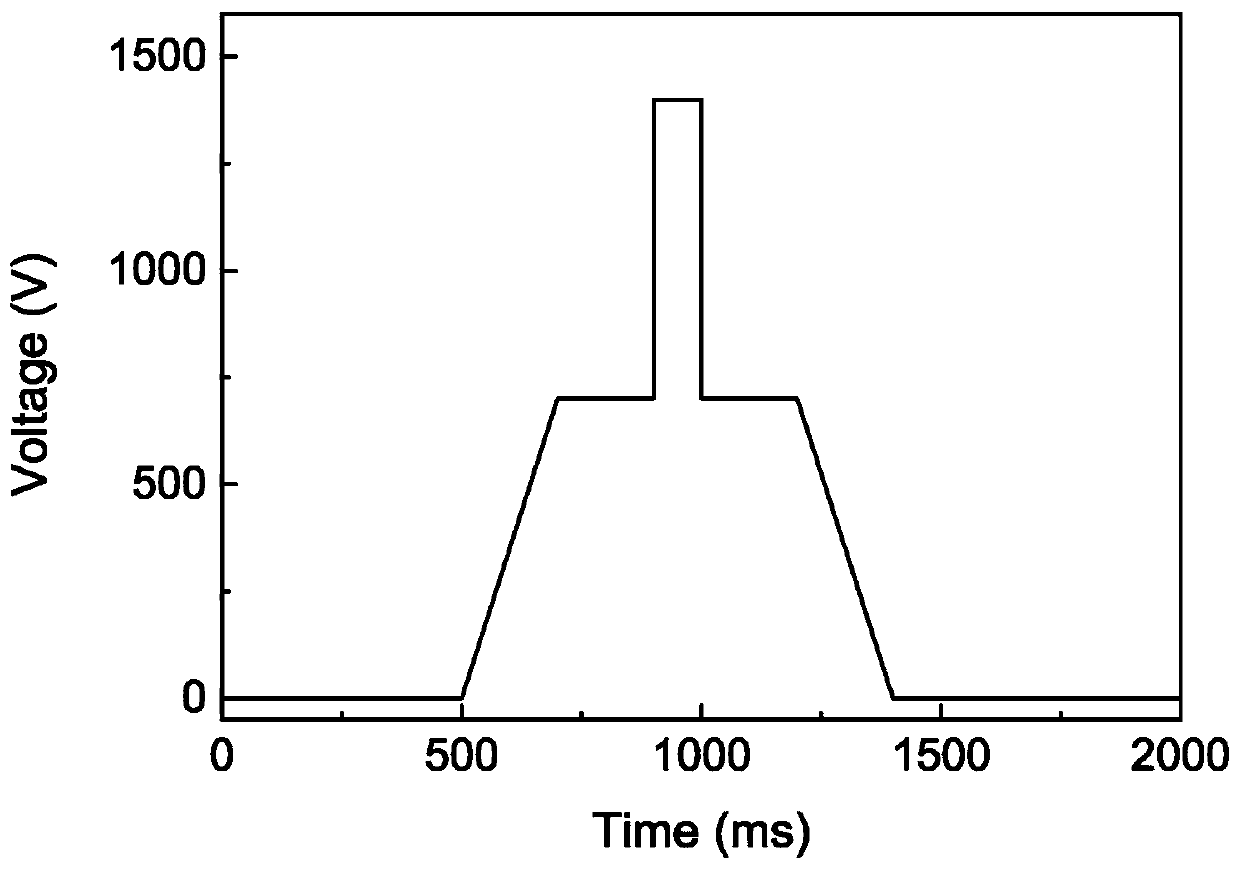

[0066] (2) After the crystal is cooled to room temperature, use the liquid electrode to reverse the crystal’s back polarization, as shown in figure 2 shown. At this time, the positive pole of the high voltage power supply is connected to the -Z surface of the initial crystal, and the negative pole of the high voltage power sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com