A kind of preparation method of propyl gallate for injection

A technology of propyl gallate and injection, which is applied in the field of preparation of propyl gallate for injection, can solve problems such as difficult to ensure decarburization effect, decrease of main drug content, complex decarburization operation, etc., achieve good solubility and simplify production Good technology and recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

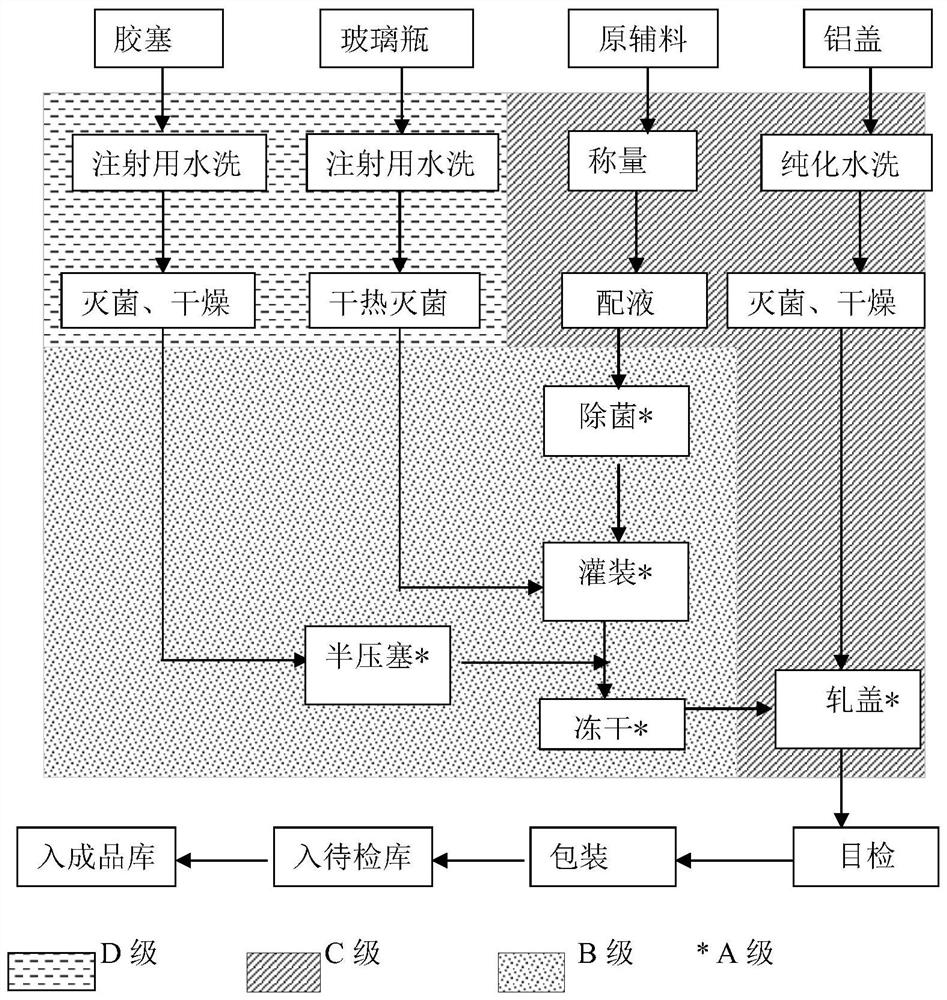

Method used

Image

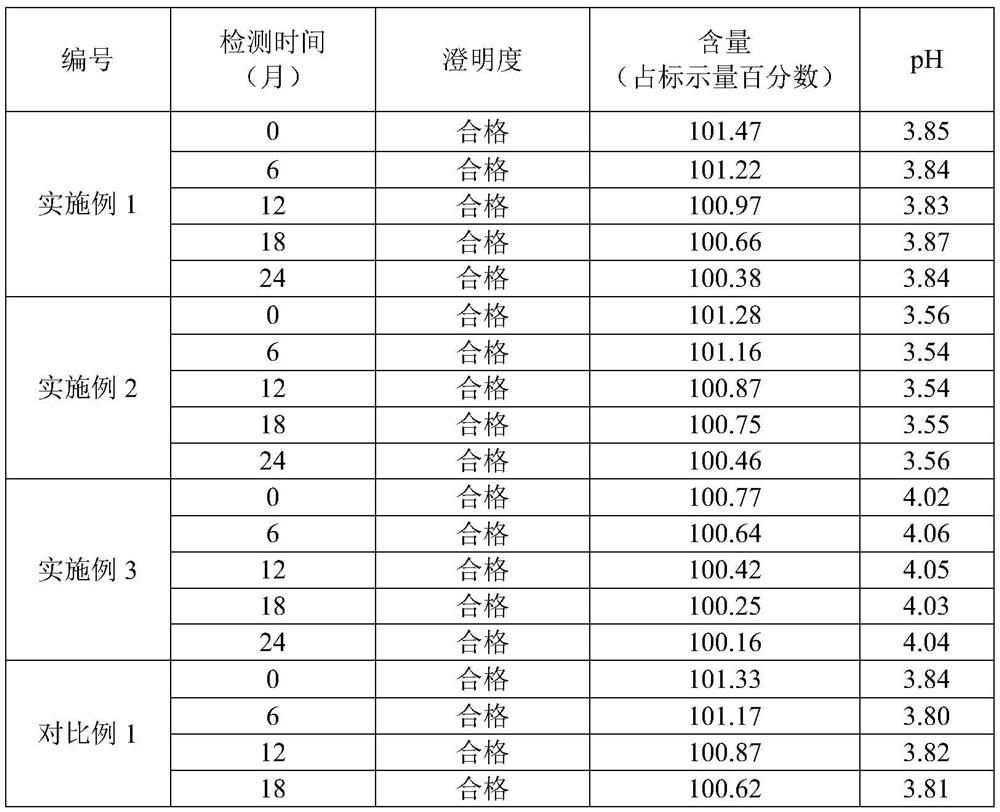

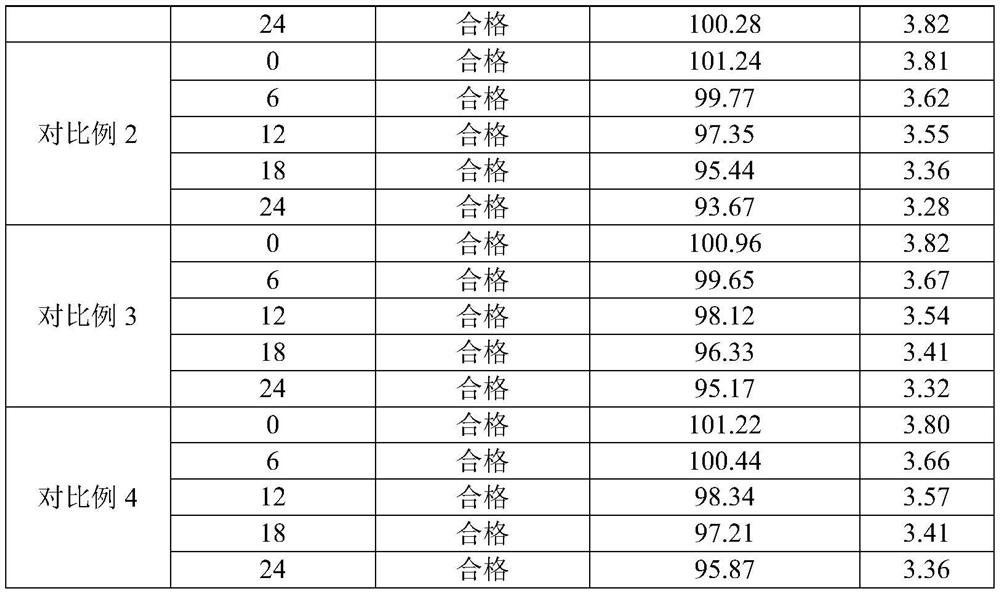

Examples

Embodiment 1

[0038] Preparation of magnetic activated carbon: Soak the activated carbon in 5% hydrochloric acid for 24h and rinse it with deionized water to neutrality; add the treated activated carbon to Fe 3+ with Fe 2+ The molar ratio of FeCl is 2:1 3 ·6H 2 O and FeSO 4 ·7H 2 In the mixed solution of O, stir for 1.5h, in which activated carbon and FeCl 3 ·6H 2 The mass ratio of O is 1:2.3; add 5mol / L NaOH solution dropwise to the mixed solution under stirring at 75°C, so that the mass ratio of NaOH to activated carbon is 4.2:1, and age at 100°C for 4h after the reaction; The precipitate was magnetically separated under the action of an external magnetic field, washed with deionized water until neutral, and dried at 80°C for later use. Before use, boil with water for injection for 35 minutes, dry at 75°C, and then bake at 180°C for 2.5 hours. .

[0039] Preparation of propyl gallate for injection:

[0040] (1) Weigh 70% water for injection at 95°C, add dextran 40, edetate disodi...

Embodiment 2

[0049] Preparation of magnetic activated carbon: Soak the activated carbon in 8% hydrochloric acid for 18 hours and then rinse it with deionized water until neutral; add the treated activated carbon to Fe 3+ with Fe 2+ The molar ratio of FeCl is 2.5:1 3 ·6H 2 O and FeSO 4 ·7H 2 In the mixed solution of O, stir for 1h, wherein activated carbon and FeCl 3 ·6H 2 The mass ratio of O is 1:2; add 2.5mol / L NaOH solution dropwise to the mixed solution under stirring at 70°C, so that the mass ratio of NaOH to activated carbon is 4:1, and age at 100°C for 2 hours after the reaction ; The precipitate was magnetically separated under the action of an external magnetic field, washed with deionized water until neutral, and dried at 80°C for later use. Before use, boil with water for injection for 30 minutes, dry at 70°C, and then bake at 170°C for 2 hours. .

[0050] Preparation of propyl gallate for injection:

[0051] (1) Weigh 70% water for injection at 90°C, add dextran 40, ede...

Embodiment 3

[0060] Preparation of magnetic activated carbon: Soak the activated carbon in 10% hydrochloric acid for 12 hours and then rinse it with deionized water to neutral; add the treated activated carbon to Fe 3+ with Fe 2+ The molar ratio of FeCl is 3:1 3 ·6H 2 O and FeSO 4 ·7H 2 In the mixed solution of O, stir for 2h, wherein activated carbon and FeCl 3 ·6H 2 The mass ratio of O is 1:3; add 4mol / L NaOH solution dropwise to the mixed solution under stirring at 80°C, so that the mass ratio of NaOH to activated carbon is 5:1, and age at 100°C for 6h after the reaction; The precipitate was magnetically separated under the action of an external magnetic field, washed with deionized water until neutral, and dried at 80°C for later use. Before use, boil with water for injection for 40 minutes, dry at 80°C, and then bake at 190°C for 3 hours.

[0061] Preparation of propyl gallate for injection:

[0062] (1) Weigh 70% water for injection at 100°C, add dextran 40, edetate disodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com