Non-uniform metamaterial for converging electromagnetic waves

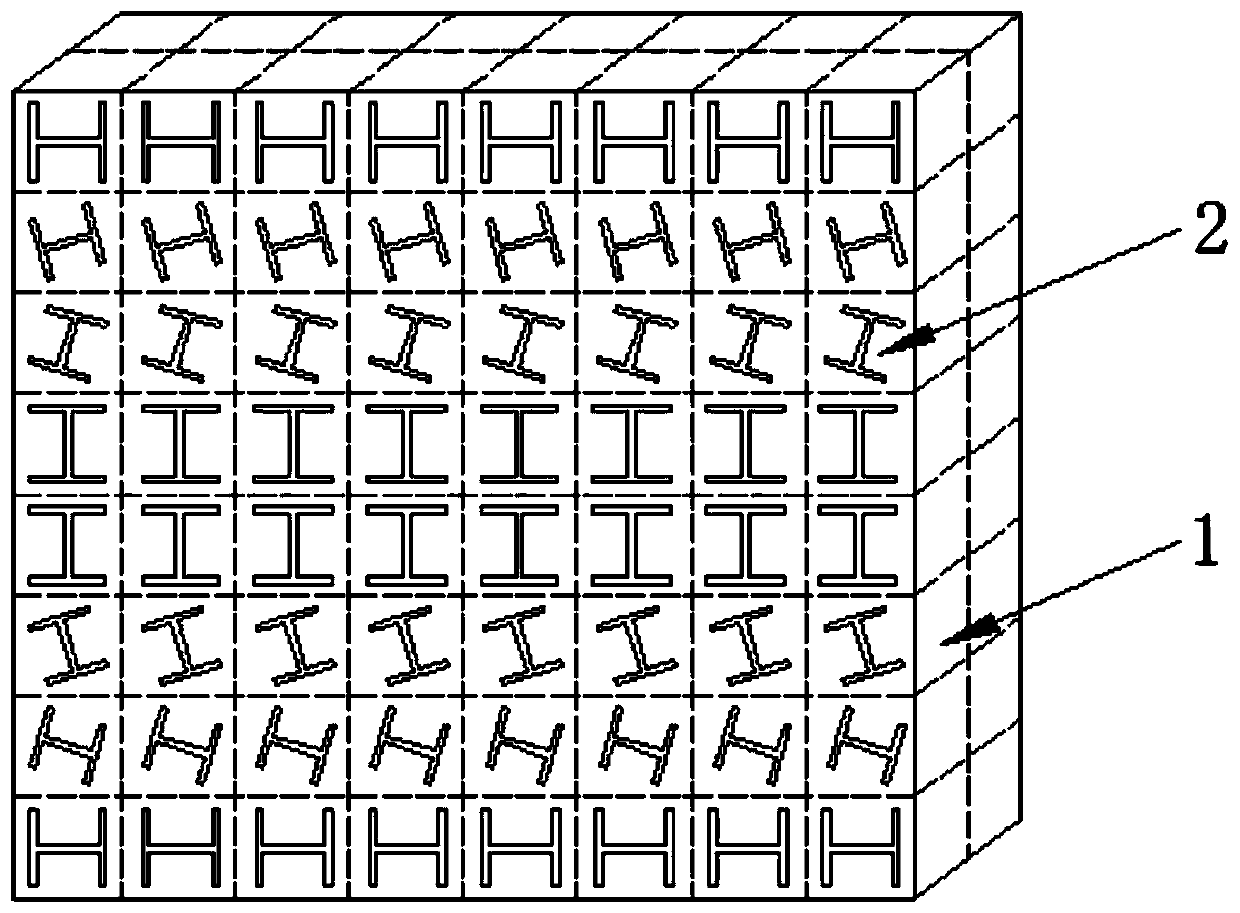

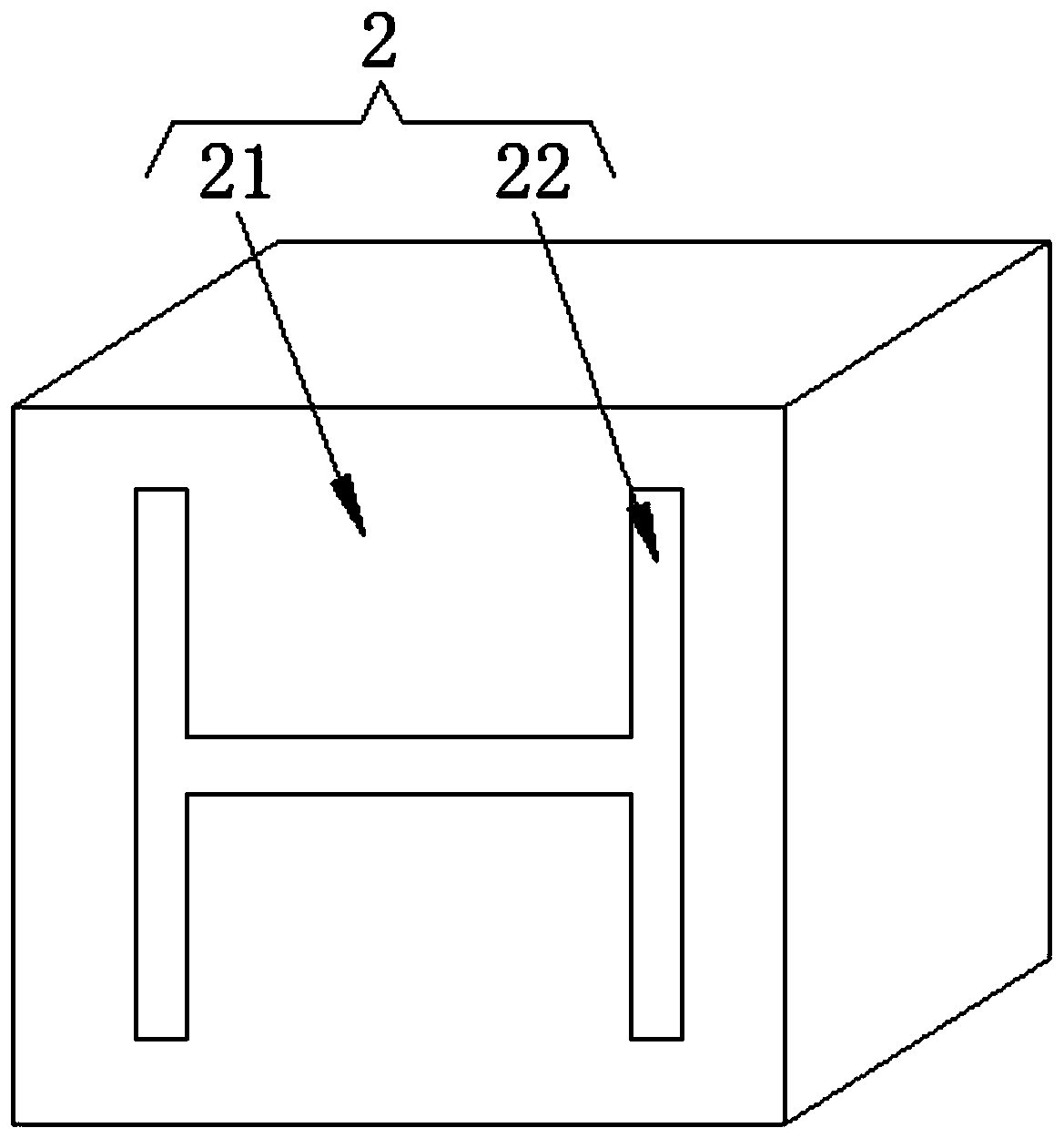

A metamaterial, non-uniform technology, applied in the field of metamaterials, can solve the problems of large size of focusing antenna, easy aging of medium, large loss, etc., to achieve the effect of enhancing the performance of convergent electromagnetic waves, flexible use, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

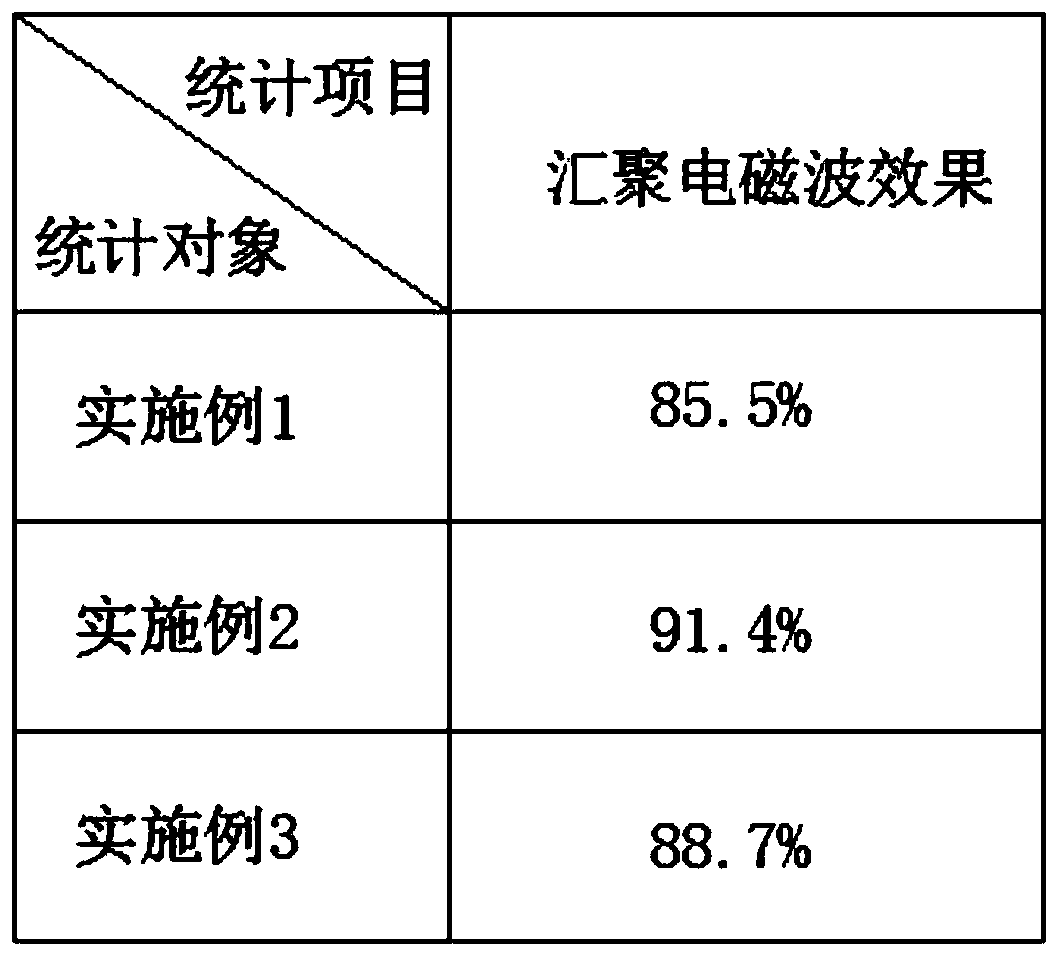

Embodiment 1

[0027] Mix and dissolve 6 parts of ferric nitrate, 4 parts of nickel nitrate, 4 parts of zinc nitrate and 1 part of cobalt powder in 15 parts of deionized water, add 25% ethylene glycol to the mixed solution, and ultrasonically disperse until it is evenly dispersed. Put it in a water bath at 45°C, slowly add sodium hydroxide solution to the mixed solution, and at the same time, stir continuously at 300 rpm for 80 minutes to obtain a mixed solution, then crystallize and dry the mixed solution and pulverize it into fine powder to obtain doped Nickel-zinc ferrite magnetic powder, uniformly mix the obtained doped nickel-zinc ferrite magnetic powder with 7 parts of binder, 5 parts of plasticizer, and 10 parts of solvent to form a slurry, and ultrasonically disperse the slurry at 25kHz for 50 minutes , cast the slurry to make a ferrite green sheet and dry it, then paste a metal film on the upper and lower surfaces of the ferrite green sheet, and then roll and compact it with a magnet...

Embodiment 2

[0029] Mix and dissolve 7 parts of iron nitrate, 5 parts of nickel nitrate, 5 parts of zinc nitrate and 2 parts of cobalt powder in 20 parts of deionized water, add 25% ethylene glycol to the mixed solution, and ultrasonically disperse until it is evenly dispersed. Put it in a water bath at 45°C, slowly add sodium hydroxide solution to the mixed solution, and at the same time, stir continuously at 300 rpm for 80 minutes to obtain a mixed solution, then crystallize and dry the mixed solution and pulverize it into fine powder to obtain doped Nickel-zinc ferrite magnetic powder, uniformly mix the obtained doped nickel-zinc ferrite magnetic powder with 8 parts of binder, 6 parts of plasticizer, and 12 parts of solvent to form a slurry, and ultrasonically disperse the slurry at 25kHz for 50 minutes , cast the slurry to make a ferrite green sheet and dry it, then paste a metal film on the upper and lower surfaces of the ferrite green sheet, and then roll and compact it with a magneti...

Embodiment 3

[0031] Mix and dissolve 8 parts of ferric nitrate, 6 parts of nickel nitrate, 6 parts of zinc nitrate and 3 parts of cobalt powder in 25 parts of deionized water, add 25% ethylene glycol to the mixed solution, and ultrasonically disperse until it is evenly dispersed. Put it in a water bath at 45°C, slowly add sodium hydroxide solution to the mixed solution, and at the same time, stir continuously at 300 rpm for 80 minutes to obtain a mixed solution, then crystallize and dry the mixed solution and pulverize it into fine powder to obtain doped Nickel-zinc ferrite magnetic powder, uniformly mix the obtained doped nickel-zinc ferrite magnetic powder with 10 parts of binder, 7 parts of plasticizer, and 15 parts of solvent to form a slurry, and ultrasonically disperse the slurry at 25kHz for 50 minutes , casting the slurry to make a ferrite green sheet and drying it, then sticking a metal film on the upper and lower surfaces of the ferrite green sheet, rolling and compacting it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com