Low viscosity high solid content wax emulsion, preparation method and emulsifier thereof

An emulsifier and wax emulsion technology, applied in the field of high solid content wax emulsion and its preparation method and emulsifier, can solve the problems of unstable system, complicated preparation process, coarse particles, etc., and save production cost and transportation cost. , The manufacturing process is simple to operate, and the dispersion and fluidity are good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

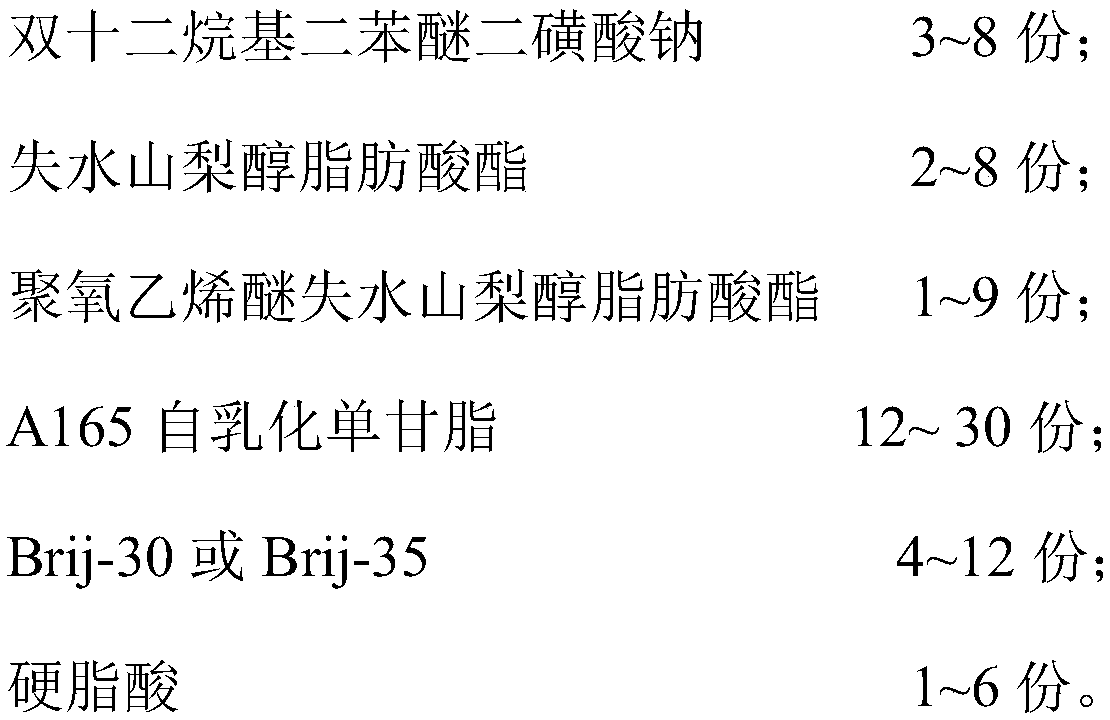

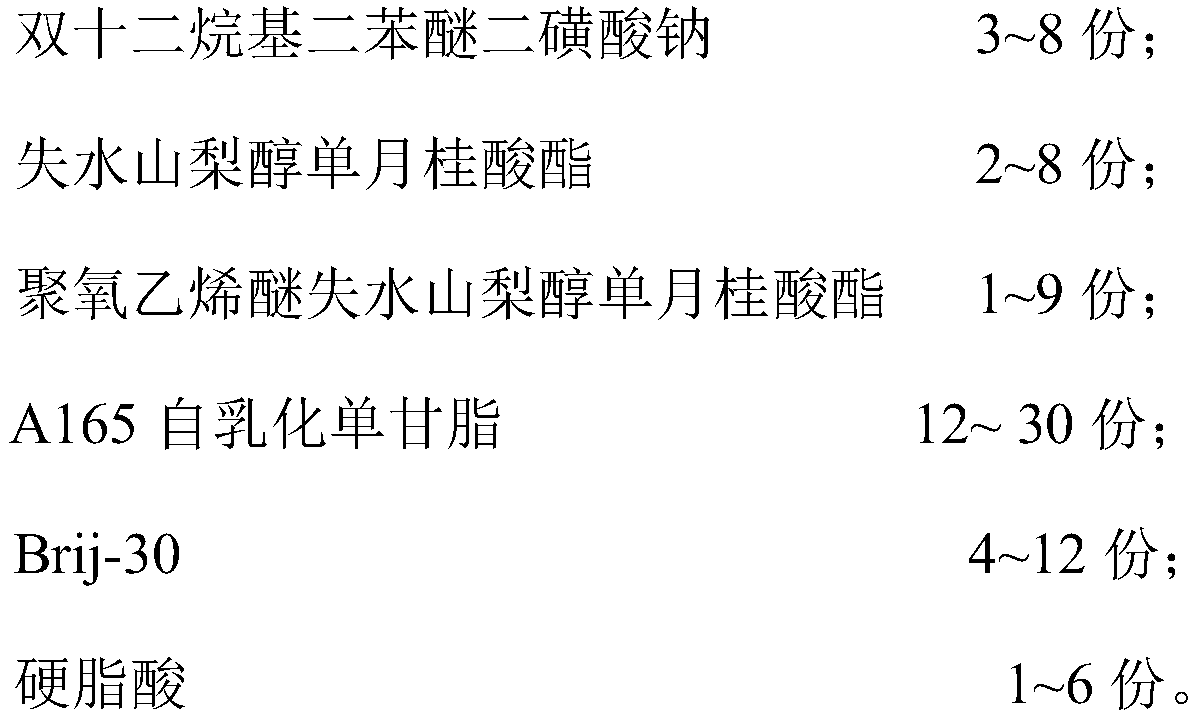

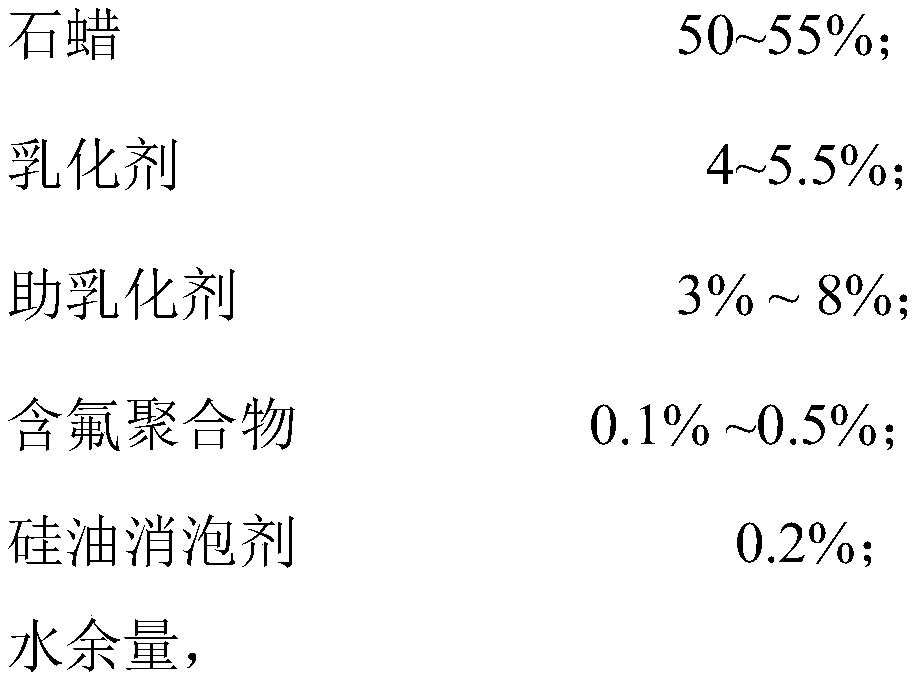

Method used

Image

Examples

Embodiment 1

[0024] This example illustrates the preparation of 100 g of a wax emulsion with a solid content of 50%.

[0025] Step 1, weigh 50g of No. 58 paraffin, 0.5g of sodium didodecyl diphenyl ether disulfonate, 0.5g of sorbitan monolaurate, and 0.5g of polyoxyethylene ether sorbitan monolaurate , A165 self-emulsifying monoglyceride 1.8g, Brij-300.6g, stearic acid 0.34g, fluoropolymer 0.1g, glycerin 5g, silicone oil defoamer 0.2g, water 40.46g.

[0026] Step 2, heating the weighed No. 58 paraffin in a water bath at 95° C. until completely melted to obtain liquid paraffin.

[0027] Step 3, the above-mentioned weighed sodium dodecyl diphenyl ether disulfonate, sorbitan monolaurate, polyoxyethylene ether sorbitan monolaurate, A165 self-emulsifying monoglyceride, Mix Brij-30, stearic acid, fluoropolymer, glycerol, silicone oil defoamer and 1 / 2 of the water weighed above by low-energy emulsification method, heat and stir to melt each raw material, and keep warm at 85°C for 10 minutes.

...

Embodiment 2

[0030] This example illustrates the preparation of 100 g of a wax emulsion with a solid content of 53%.

[0031] Step 1, weigh 53g of No. 58 paraffin, 0.6g of sodium didodecyl diphenyl ether disulfonate, 0.2g of sorbitan monooleate, 0.1g of polyoxyethylene ether sorbitan monooleate , A165 self-emulsifying monoglyceride 1.5g, Brij-30 1.2g, stearic acid 0.5g, fluoropolymer 0.3g, 1,3-propanediol 6g, silicone oil defoamer 0.2g, water 36.4g.

[0032] Step 2, heating the weighed No. 58 paraffin in a water bath at 95° C. until completely melted to obtain liquid paraffin.

[0033] Step 3, the above-mentioned weighed sodium didodecyl diphenyl ether disulfonate, sorbitan monooleate, polyoxyethylene ether sorbitan monooleate, A165 self-emulsifying monoglyceride, Brij-30, stearic acid, fluoropolymer, 1,3-propanediol, silicone oil defoamer and 1 / 2 of the above-mentioned weighed water are mixed evenly by low-energy emulsification method, heated and stirred to melt each raw material, and ke...

Embodiment 3

[0036] This example illustrates the preparation of 100 g of a wax emulsion with a solid content of 52%.

[0037] Step 1, weigh 52g of microcrystalline paraffin, 0.8g of sodium didodecyl diphenyl ether disulfonate, 0.7g of sorbitan monostearate, and 0.9g of polyoxyethylene ether sorbitan monostearate , A165 self-emulsifying monoglyceride 1.2g, Brij-35 0.4g, stearic acid 0.34g, fluoropolymer 0.6g, 1,2-propylene glycol 3g, silicone oil defoamer 0.2g, water 39.86g.

[0038] Step 2, heating the weighed microcrystalline paraffin in a water bath at 95° C. until completely melted to obtain liquid paraffin.

[0039]Step 3, the above-mentioned weighed sodium didodecyl diphenyl ether disulfonate, sorbitan monostearate, polyoxyethylene ether sorbitan monostearate, A165 self-emulsifying monoglyceride, Brij-35, stearic acid, fluoropolymer, 1,2-propanediol, silicone oil defoamer and 1 / 2 of the above-mentioned weighed water are mixed evenly by low-energy emulsification method, heated and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com