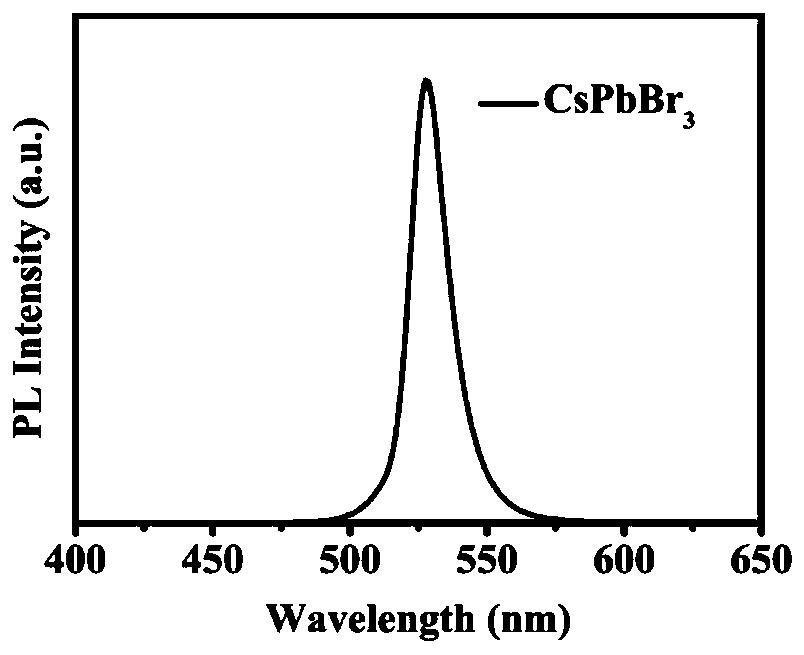

Ultra-small perovskite quantum dots and preparation method thereof

A perovskite and quantum dot technology, applied in chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of difficult size control and easy agglomeration, and achieve easy size control, difficult to agglomerate, and simplification. The effect of the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of ultra-small perovskite quantum dots, comprising the following steps:

[0036] (1) Weigh 0.105g of cesium bromide and 0.138g of lead bromide solid powder and dissolve them in a beaker with 10ml of ethanol, stir for 30min to dissolve them, and keep warm at 40°C for 30min to obtain the reactant precursor solution for later use;

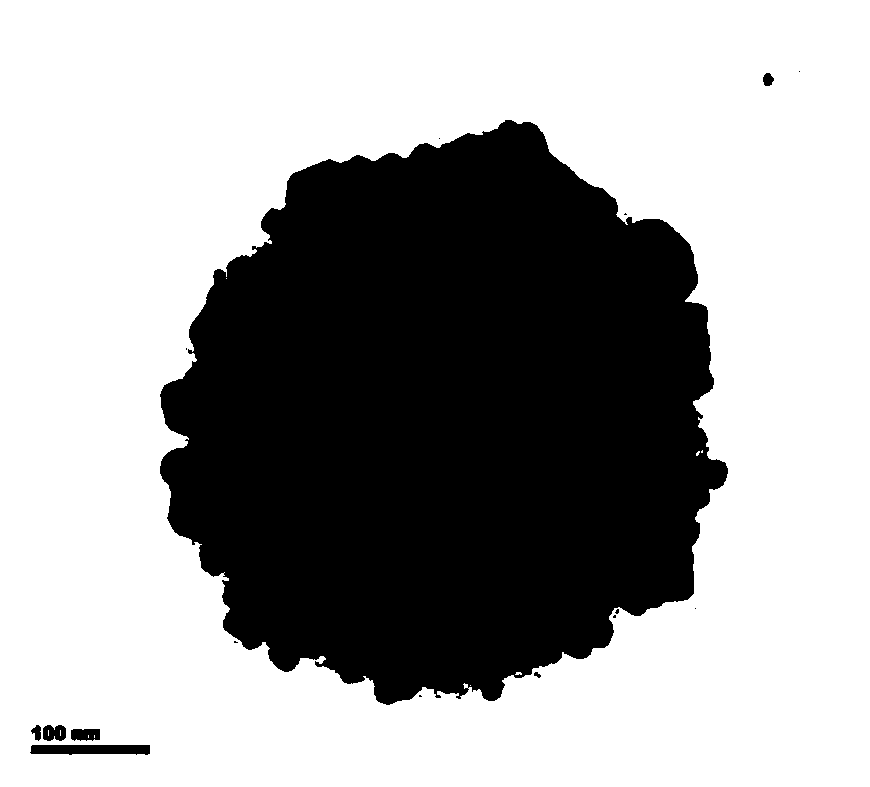

[0037] (2) Disperse 9.235 mg of mesoporous silica powder in a chloroform solution containing 1 ml of oleylamine and 1 ml of oleic acid and stir for 30 min, then place the mesoporous silica suspension in ice water for later use, wherein the concentration of mesoporous silica is 1.85×10 -3 g / ml;

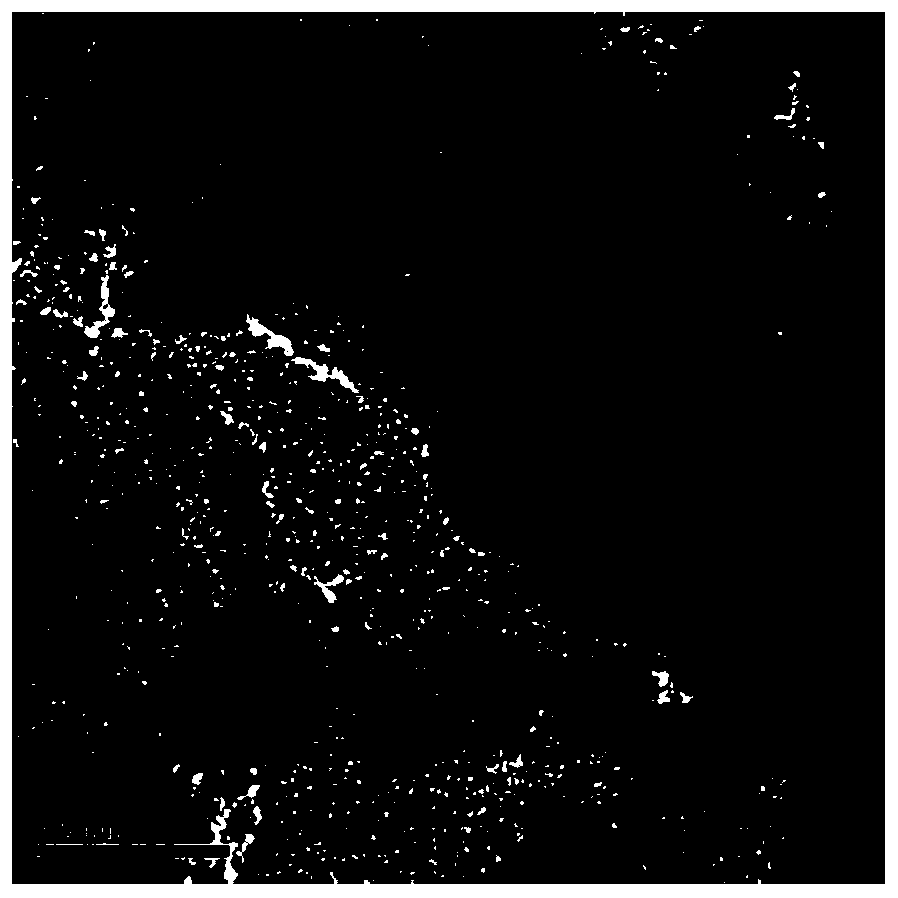

[0038] (3) Take 1ml of the above precursor solution and quickly inject it into 5ml of mesoporous silica suspension, keep stirring for 5min, and obtain perovskite quantum dots dispersed in mesoporous silica through repeated washing, centrifugation, dispersion and other processes.

[0039] The mesoporous silica used in the preparati...

Embodiment 2

[0042] A preparation method of ultra-small perovskite quantum dots, comprising the following steps:

[0043] (1) Weigh 0.105g of cesium bromide and 0.138g of lead bromide solid powder and dissolve them in a 10ml ethanol beaker, stir for 30min to dissolve them, and keep warm at 50°C for 30min to obtain the reactant precursor solution for later use;

[0044] (2) Disperse 18.47mg of mesoporous silica powder in a chloroform solution containing 1ml of oleylamine and 1ml of oleic acid and stir for 30min, then place the mesoporous silica suspension in ice water for later use, wherein the concentration of mesoporous silica is 2.31×10 -3 g / ml;

[0045] (3) Take 1ml of the above precursor solution and quickly inject it into 8ml of mesoporous silica suspension, continue to stir for 8min, and obtain perovskite quantum dots dispersed in mesoporous silica through repeated washing, centrifugation, dispersion and other processes.

[0046] The mesoporous silica used in the preparation proces...

Embodiment 3

[0049] A preparation method of ultra-small perovskite quantum dots, comprising the following steps:

[0050] (1) Weigh 0.105g of cesium bromide and 0.138g of lead bromide solid powder and dissolve them in a 10ml ethanol beaker, stir for 30min to dissolve them, and keep warm at 60°C for 30min to obtain the reactant precursor solution for later use;

[0051] (2) Disperse 92.35 mg of mesoporous silica powder in a chloroform solution containing 1 ml of oleylamine and 1 ml of oleic acid and stir for 30 min, then place the mesoporous silica suspension in ice water for later use, wherein the concentration of mesoporous silica is 9.23×10 -3 g / ml;

[0052] (3) Take 1ml of the above precursor solution and quickly inject it into 10ml of mesoporous silica suspension, keep stirring for 10min, and obtain perovskite quantum dots dispersed in mesoporous silica through repeated washing, centrifugation, dispersion and other processes.

[0053] The mesoporous silica used in the preparation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com