High-purity decoloration filter pressing process of sulfadoxine

A high-purity technology of sulfonamide, which is applied in the fields of filtration and separation, membrane filter, fixed filter element filter, etc., can solve the problem of not specifically disclosing the method of fine processing and purification of crude sulfonamide, high impurity content, and inability to be directly applied, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: add 4500kg water in dissolving pot, add under heating and stirring 285kg of the sulfonamide crude product that is made by CN102391190A embodiment 1, add 67.5kg calcium hydroxide and adjust pH value to 12, after fully dissolving, add 22.5kg respectively Activated carbon and 22.5kg acidic preactivated pore-enlarging activated carbon are used for decolorization, and the temperature is at 90° C., and it is incubated for 70 minutes; The temperature is set at 10°C, and all the comparative examples and examples below are the same as the implementation conditions), centrifuged and dehydrated; the filter cake is washed with water until the liquid outlet is clarified, and the centrifuged and dried discharge is dried by a double-cone rotary vacuum drier to obtain Zhou The finished product of sulfonamide has a purity of about 99.99%.

Embodiment 2

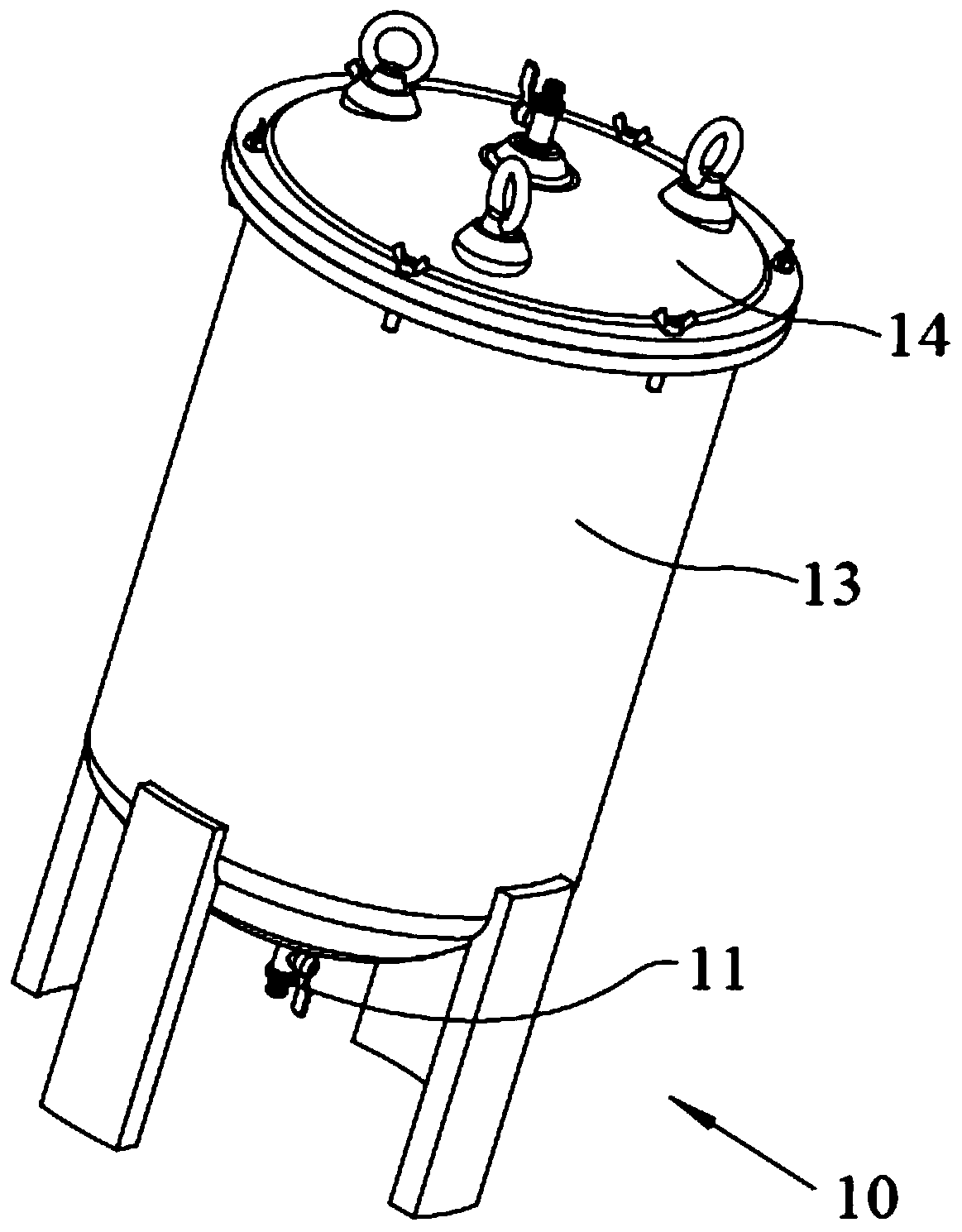

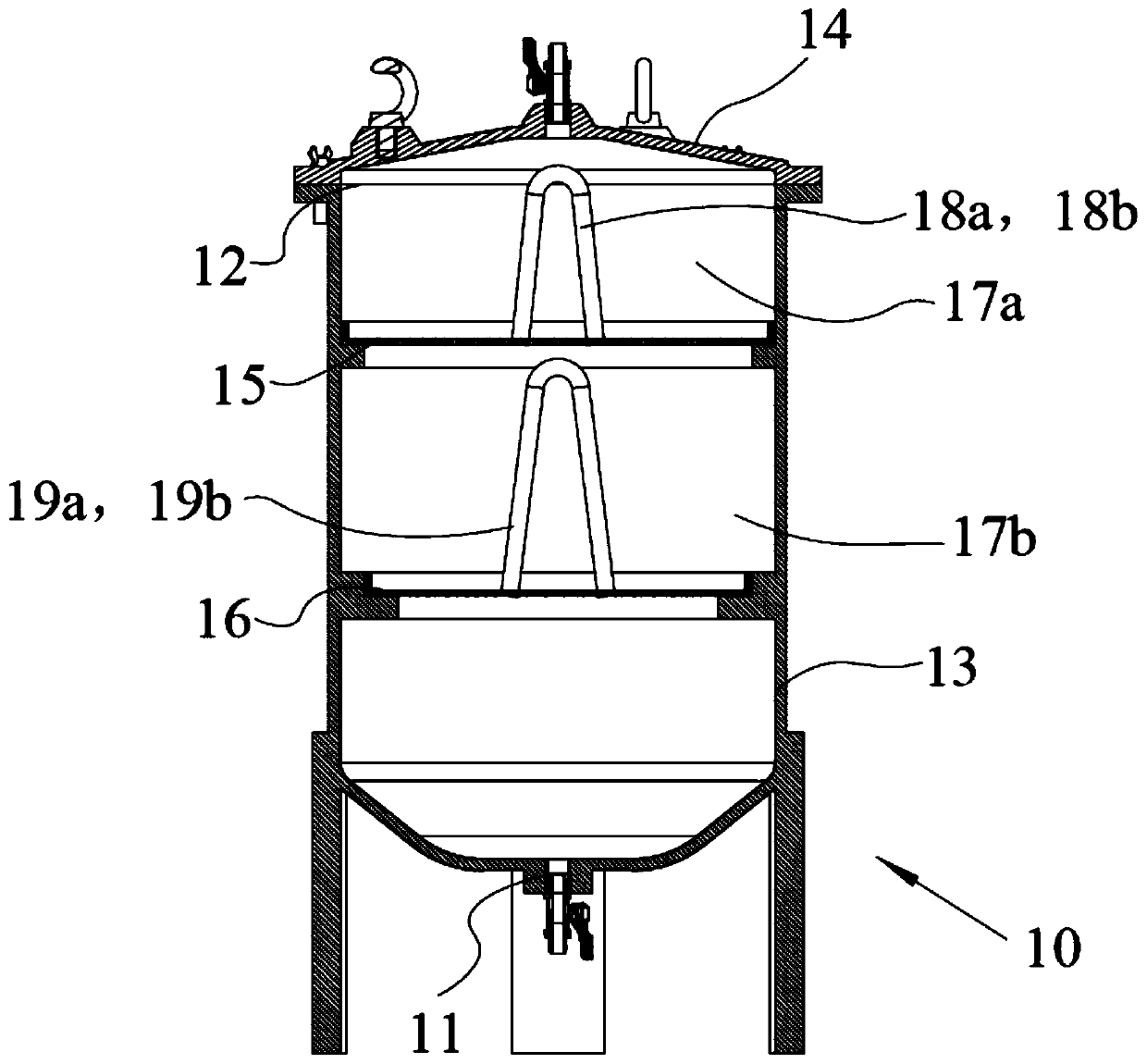

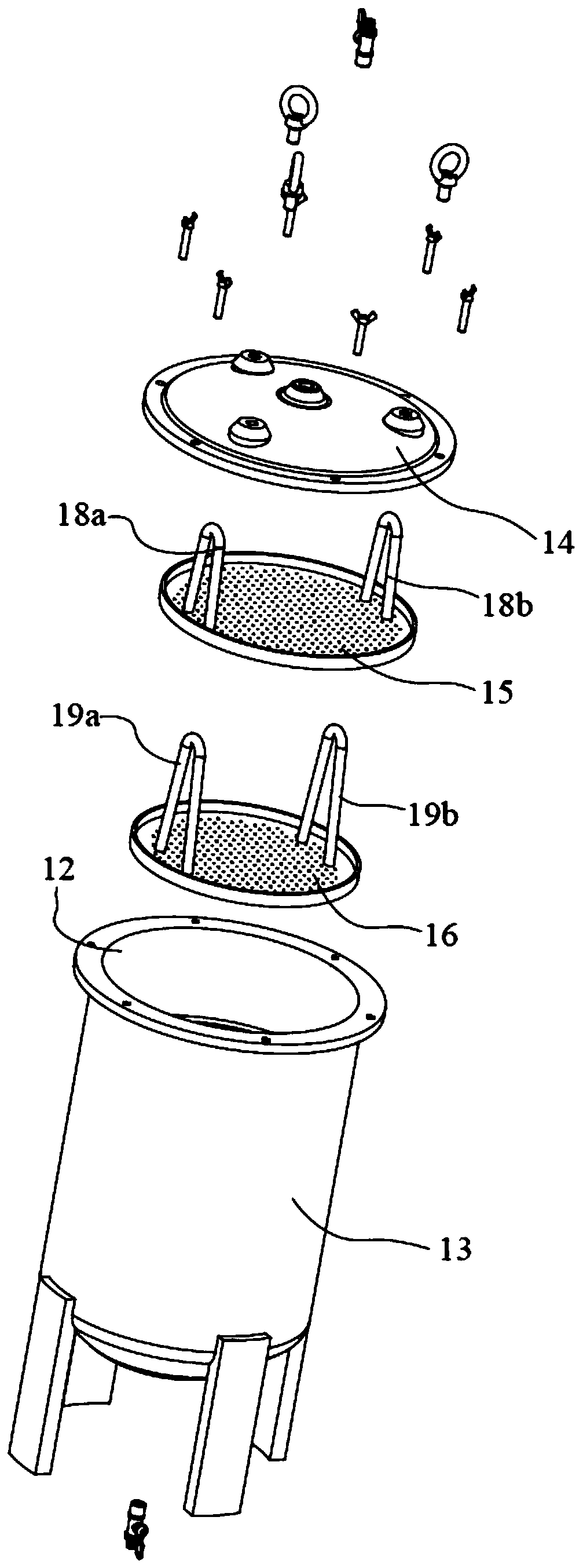

[0038] Embodiment 2: add 4500kg water in dissolving pot, add under heating and stirring 285kg of the sulfonamide crude product that is made by CN102391190A embodiment 1, add 67.5kg calcium hydroxide and adjust pH value to 12, after fully dissolving, add 45kg activated carbon decolorization , the temperature is at 90°C, and it is incubated for 70 minutes; after cooling, the pressure filter 10 provided by the present embodiment is filtered and then sent to the fine crystallization pot for cooling and recrystallization. Glacial acetic acid solution, until the pH value is 5.5, after retesting unchanged, centrifugal dehydration; wash the filter cake with water until the liquid outlet is clarified, centrifugally dry and discharge the material and use a double-cone rotary vacuum dryer to dry to obtain the finished product of sulfonamide, which has a purity of It is about 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com