Sodium bicarbonate dry method desulfurization ash resourceful treatment method

A dry desulfurization ash and treatment method technology, applied in the field of circular economy, achieves significant economic and social benefits, and solves environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

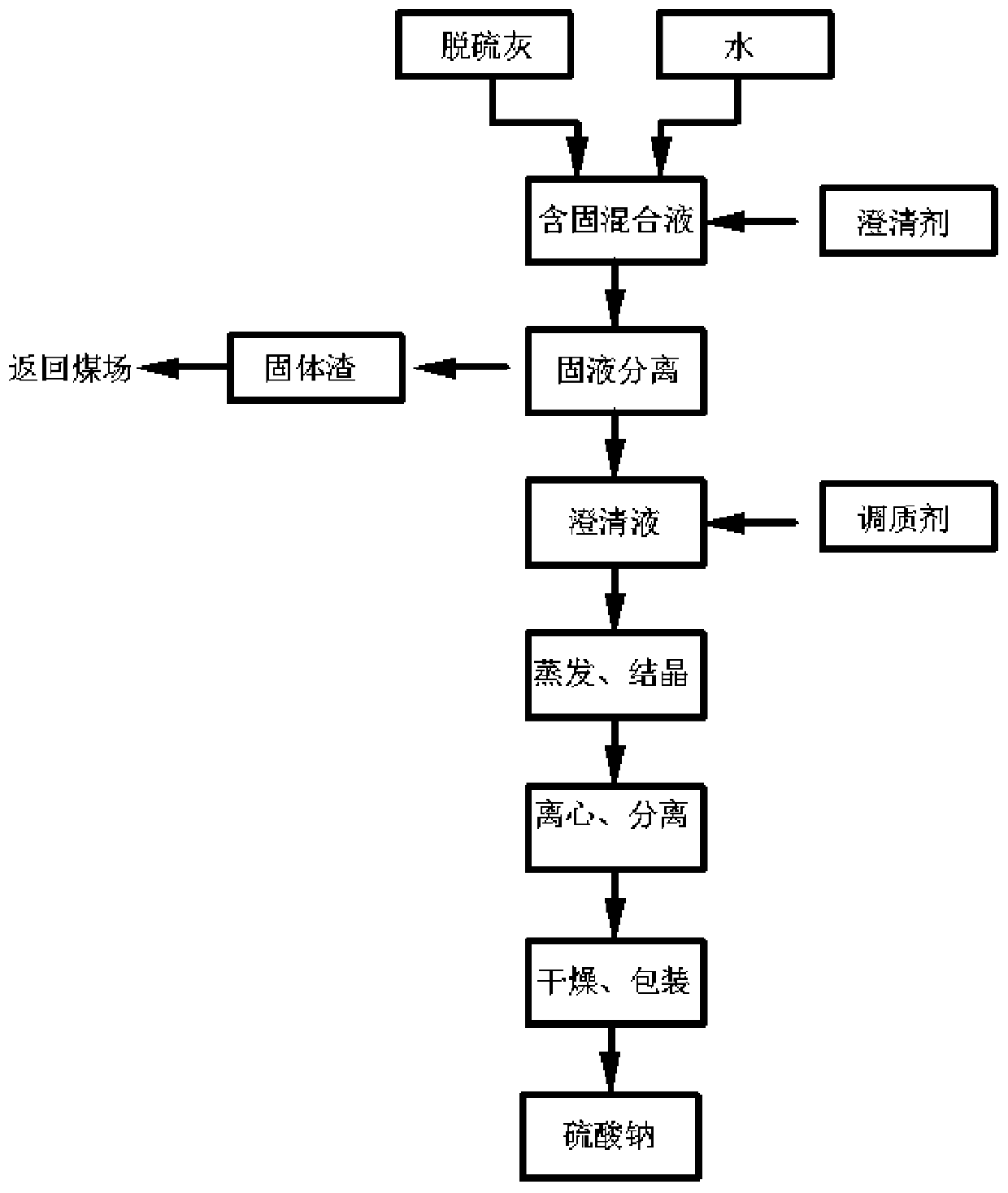

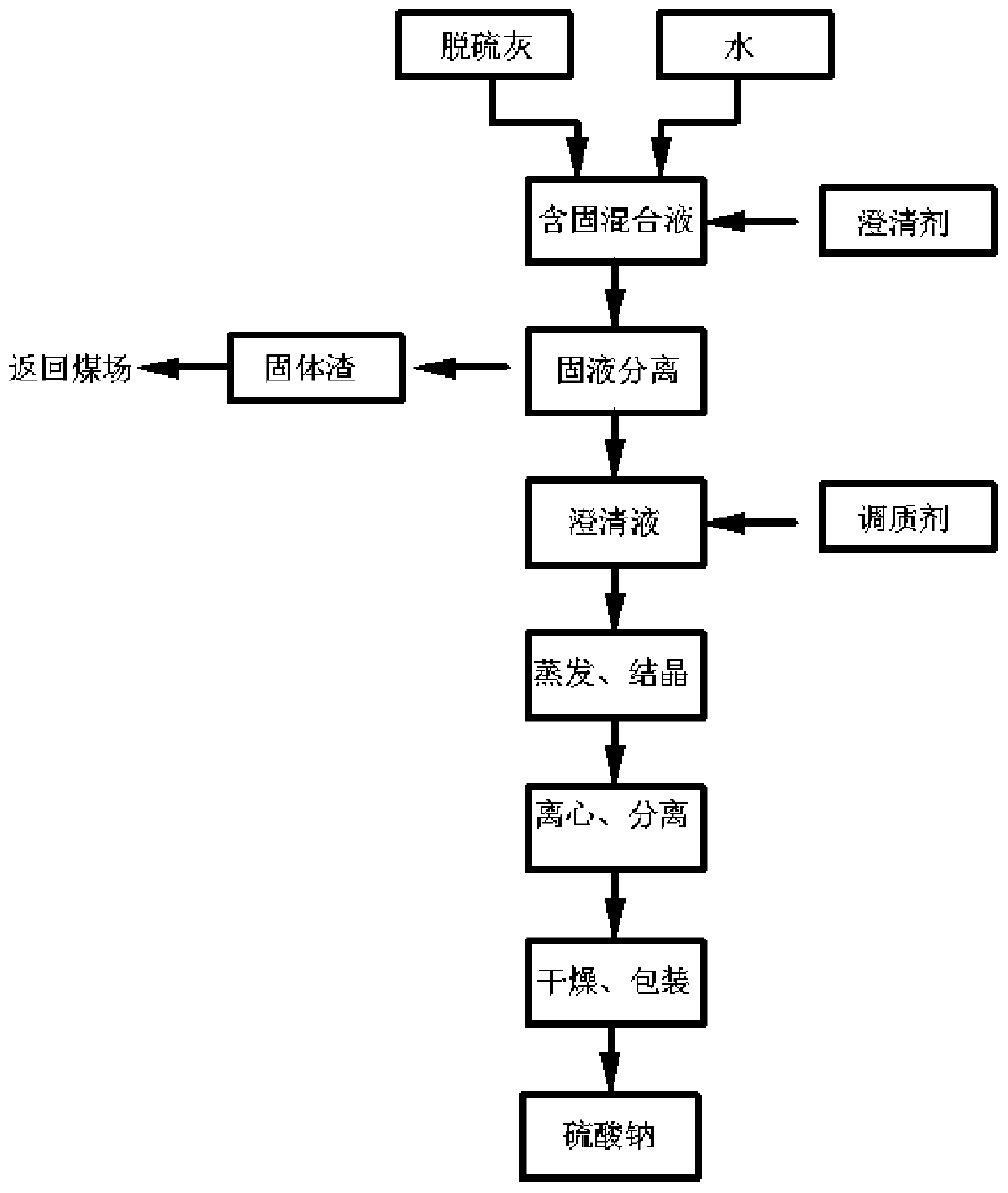

Method used

Image

Examples

Embodiment 1

[0022] At room temperature, use a liquid-solid ratio of 2.2:1 to dissolve and dilute baking soda dry desulfurization ash with industrial clean water or condensed water in the production process (the temperature of the water is controlled at 35-85 degrees, and steam heating is used when the water temperature is low). At the same time, clarifiers PAC and PAM were added, compressed air was introduced, and the slurry was stirred for 30 minutes to obtain a uniform slurry. During the stirring process, monitor the temperature of the slurry, and when the temperature is lower than 35 degrees, heat the slurry to rise to 35-85 degrees. Stop stirring and heating, and let it stand for 60-90 minutes. When the suspended matter in the slurry is completely settled, discharge the sediment at the bottom, press filter the sediment, and send the obtained filter cake to the gas coal yard. The filter press filtrate can be recycled for use in Dilute the desulfurization ash; filter the upper clarified...

Embodiment 2

[0024] At room temperature, use a liquid-solid ratio of 2.5:1, use industrial clean water or condensed water in the production process (the temperature of the water is controlled at 35-85 degrees, and use steam heating when the water temperature is low) to dissolve and dilute the dry desulfurization ash of baking soda, Add PAC and PAM at the same time, feed compressed air, and stir the slurry for 30 minutes to obtain a uniform slurry. During the stirring process, monitor the temperature of the slurry, and when the temperature is lower than 35 degrees, heat the slurry to rise to 35-85 degrees. Stop stirring and heating, and let it stand for 60-90 minutes. When the suspended matter in the slurry is completely settled, discharge the sediment at the bottom, press filter the sediment, and send the obtained filter cake to the gas coal yard. The filter press filtrate can be recycled for use in Dilute desulfurization ash. Filter the upper clear liquid after the suspension is complete...

Embodiment 3

[0026] At room temperature, use a liquid-solid ratio of 3:1, dissolve and dilute baking soda dry desulfurization ash with industrial clean water or condensed water in the production process (the temperature of the water is controlled at 35-85 degrees), and add PFC at the same time to carry out the slurry Mechanical stirring was performed for 30 minutes to obtain a homogeneous slurry. During the stirring process, monitor the temperature of the slurry, and when the temperature is lower than 35 degrees, heat the slurry to rise to 35-85 degrees. Stop stirring and heating, and let it stand for 60-90 minutes. When the suspended matter in the slurry is completely settled, discharge the sediment at the bottom, press filter the sediment, and send the obtained filter cake to the gas coal yard. The filter press filtrate can be recycled for use in Dilute the desulfurization ash; filter the upper clear liquid after the suspension is completely precipitated, add sulfuric acid to the obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com