Preparation method of nano cuprous oxide

A nano-cuprous oxide and mixed solution technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of poor reproducibility and effective control of crystal morphology, and achieve the effects of simple method, narrow particle size distribution and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of nano-cuprous oxide, characterized in that, proceed as follows:

[0029] (1) Under magnetic stirring, in 40mL of 0.5mol / L CuSO 4 Add 80mL of 1.5mol / L NaOH aqueous solution to the aqueous solution, and then continue magnetic stirring for 30min to prepare the mixed solution A;

[0030] (2) Take 100mL of 0.25mol / L ascorbic acid, 2mL of oleic acid, and 1.06g of PVP k30, mix and stir for 30min, and prepare the mixture B;

[0031] (3) Add the mixed solution B to the mixed solution A drop by drop, and then stir for 35 minutes. The volume ratio of the mixed solution A to the mixed solution B is 1.1:0.9;

[0032] (4) Centrifuge to filter out the red precipitate formed by the reaction, wash with absolute ethanol and deionized water successively, and dry at 60°C for 8 hours.

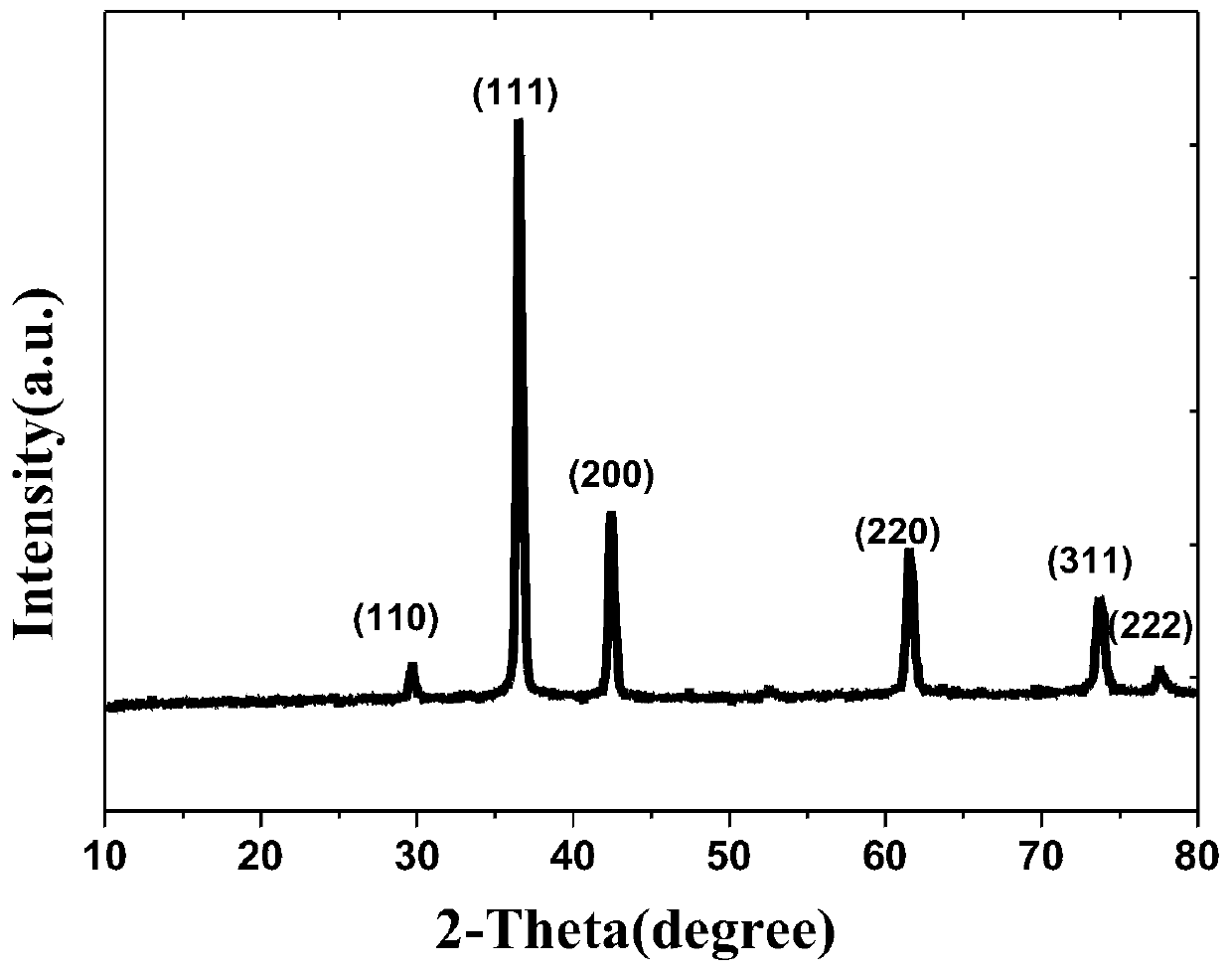

[0033] XRD detection conditions of cuprous oxide:

[0034] The radiation source is a Cu target, the wavelength is 1.54060 m, the scanning angle is 20°-80°, the voltage is 30 kV, the...

Embodiment 2

[0038] A preparation method of nano-cuprous oxide, characterized in that, proceed as follows:

[0039] (1) Under magnetic stirring, in 50mL of 0.5mol / L CuSO 4 Add 100mL of 1.5mol / L NaOH aqueous solution to the aqueous solution, and then continue magnetic stirring for 30min to prepare the mixed solution A;

[0040] (2) Take 120mL of 0.25mol / L ascorbic acid, 2.4mL of oleic acid, and 1.27g of PVP k30, mix and stir for 35min, and prepare the mixture B;

[0041] (3) Add the mixed solution B to the mixed solution A drop by drop, and then stir for 30 minutes. The volume ratio of the mixed solution B to the mixed solution A is 1.2:1;

[0042] (4) The red precipitate generated by the reaction was filtered by centrifugation, washed with absolute ethanol and deionized water in turn, and then dried at 60°C for 8 hours.

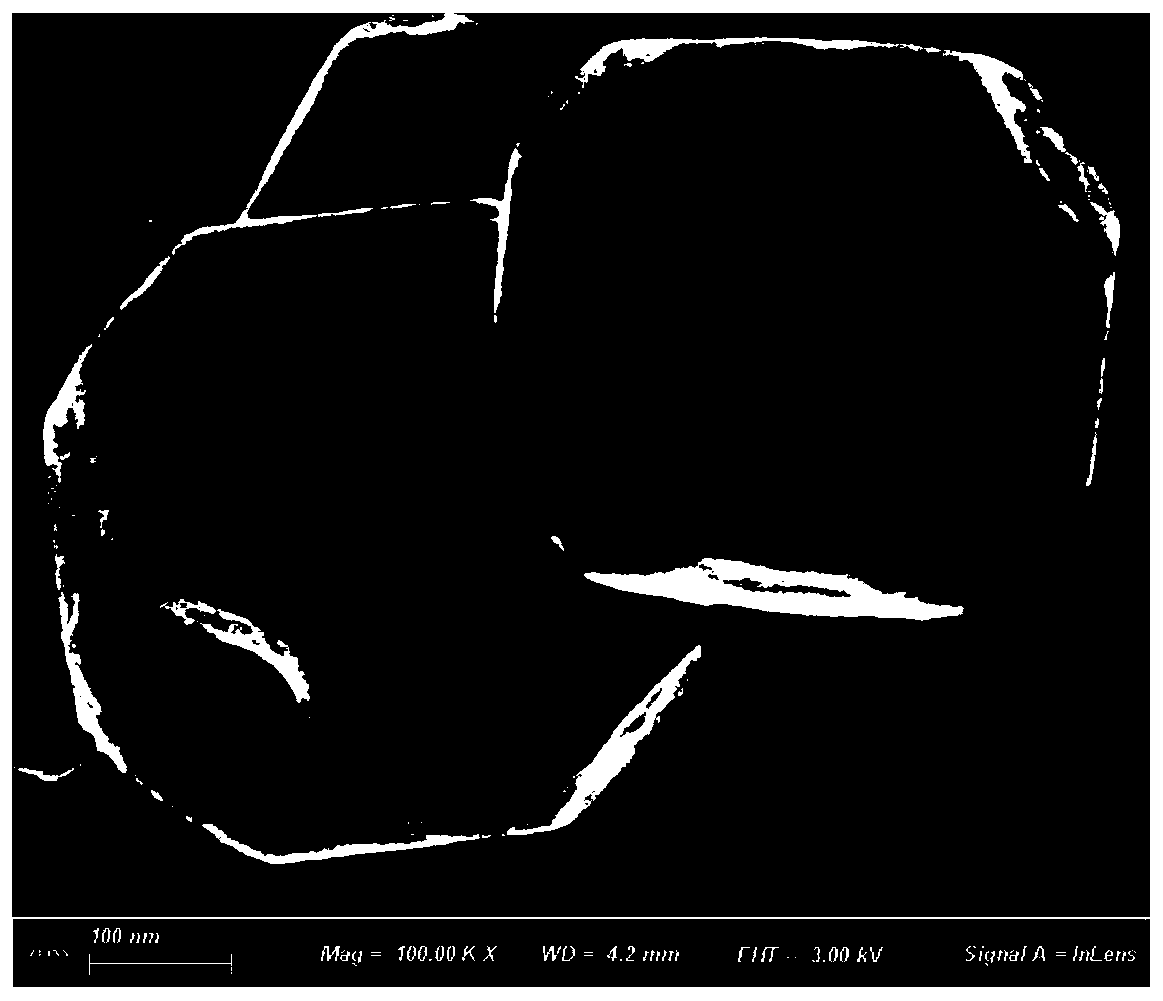

[0043] The nanometer cuprous oxide that present embodiment 1 prepares is as figure 2As shown, they are all octahedral structures with chamfered corners and chamfered ...

Embodiment 3

[0045] A preparation method of nano-cuprous oxide, characterized in that, proceed as follows:

[0046] (1) Under magnetic stirring, in 60mL of 0.5mol / L CuSO 4 Add 120mL of 1.5mol / L NaOH aqueous solution to the aqueous solution, and then continue magnetic stirring for 20min to prepare the mixed solution A;

[0047] (2) Take 150mL of 0.25mol / L ascorbic acid, 3mL of oleic acid, and 1.59g of PVP k30, mix and stir for 40min, and prepare the mixture B;

[0048] (3) Add the mixed solution B to the mixed solution A drop by drop, and then stir for 40 minutes. The volume ratio of the mixed solution B to the mixed solution A is 1.15:0.95;

[0049] (4) The red precipitate generated by the reaction was filtered by centrifugation, washed with absolute ethanol and deionized water in turn, and then dried at 60°C for 8 hours.

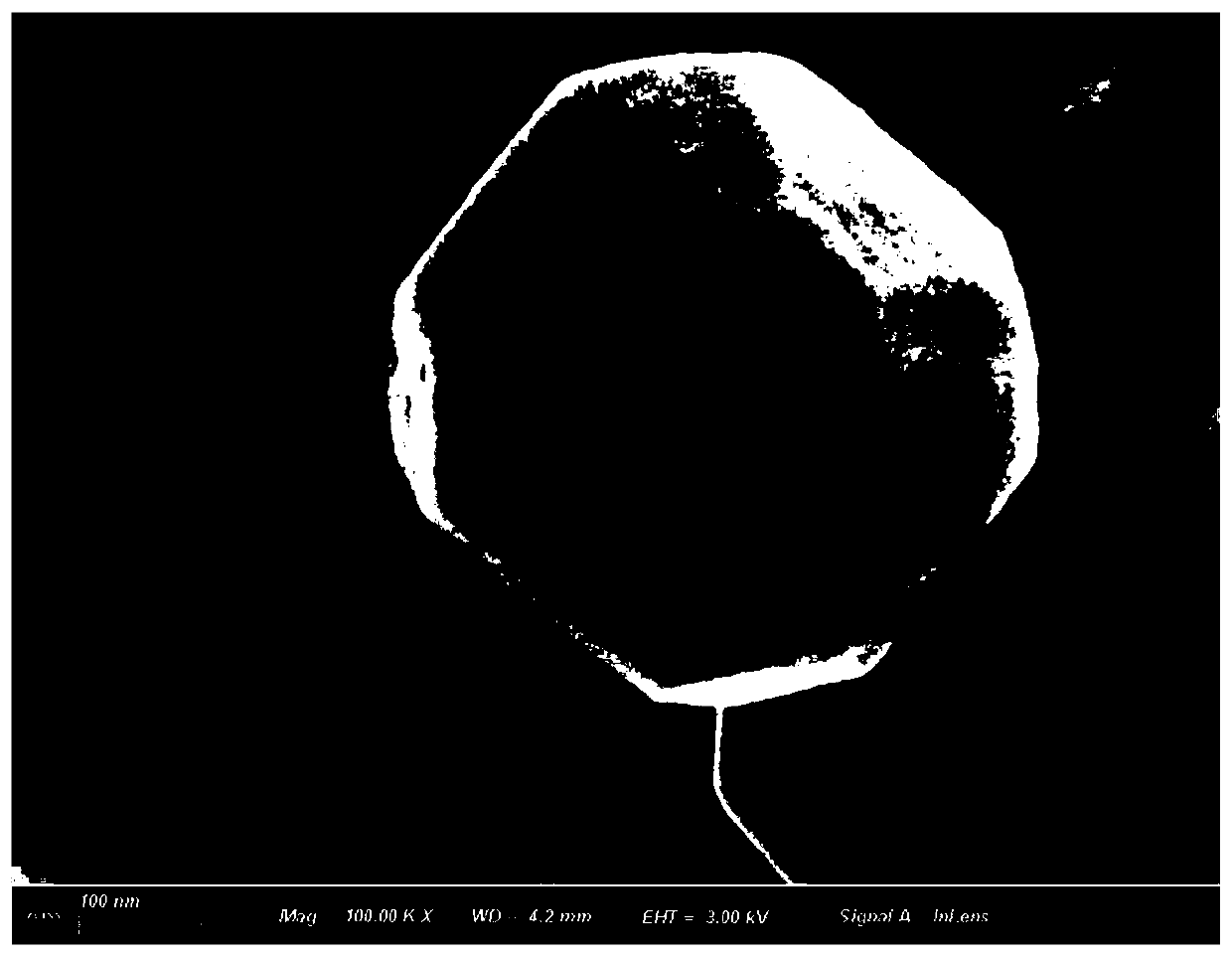

[0050] The nano-cuprous oxide prepared in Example 3 has a regular appearance and an octahedral structure with chamfered corners and chamfered edges, and its particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com