Method for preparing spherical 1,1-diamino-2,2-dinitroethylene crystal assisted by ultrasonic assistance

A technology of dinitroethylene and diamino is applied in the direction of purification/separation of amino compounds, nitration of acyclic/alicyclic/heterocyclic amine explosive compositions, organic chemistry, etc., and can solve the problems of rough surface and uneven particle size, etc. Achieve narrow particle size distribution, good dispersion and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Measure 20 mL of dimethyl sulfoxide and 10 mL of acetone, weigh 0.05% of the initial amount of FOX-7 additive polyethylene glycol 600, and add it to the crystallization kettle, which is in a constant temperature water bath at 25°C; 9.2 g Powdered FOX-7 raw materials were added into the organic solvent, and the stirrer was turned on at a stirring rate of 500 r / min to completely dissolve FOX-7. Start the dropping device to add ethyl acetate dropwise to the crystallization kettle, and add dropwise while stirring. The stirring rate is 500 r / min, the dropping rate is 0.6mL / min, and the total amount of ethyl acetate is 100mL. After all the drops are completed, the crystals are ultrasonically treated in the mother liquor, and ultrasonically treated while stirring. The stirring rate is 500 r / min, the ultrasonic frequency is 50KHz, and the ultrasonic time is 2h; after filtering, washing and drying, it can be obtained Spherical FOX-7 crystals.

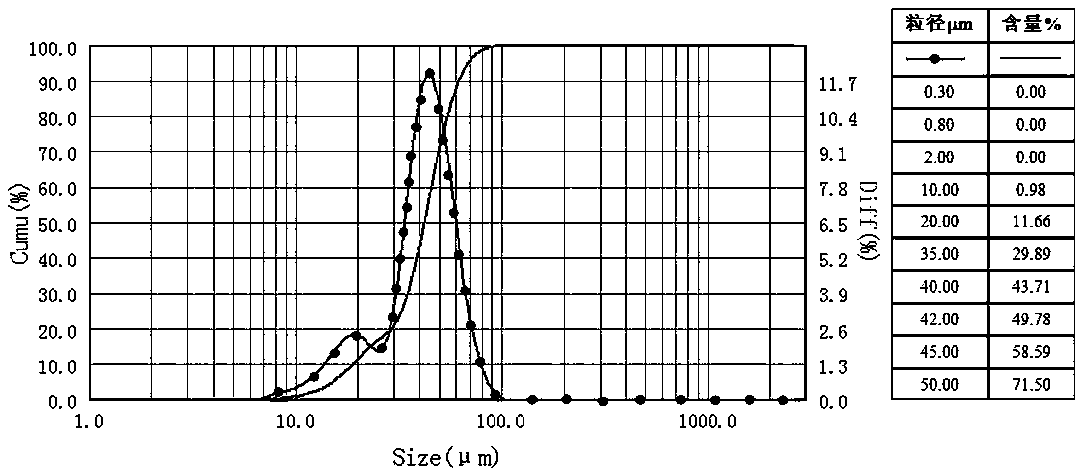

[0034] figure 1 It is the optica...

Embodiment 2

[0037] Measure 30 mL of dimethyl sulfoxide, weigh the additive polyethylene glycol 4000 whose weight is 1% of the initial amount of FOX-7, and add it to the crystallization kettle, which is placed in a constant temperature water bath at 23 °C. Add 8.5 g of powdered FOX-7 raw materials into the organic solvent, start the stirrer, and stir at a rate of 300 r / min to completely dissolve FOX-7. Start the dropping device to add acetone dropwise to the crystallization kettle, and add dropwise while stirring. The stirring rate is 300 r / min, the dropping rate is 3mL / min, and the total consumption of acetone is 150mL. After all the addition was completed, the crystals were ultrasonically treated in the mother liquor, and the ultrasonic treatment was performed while stirring. The stirring rate was 300 r / min, the ultrasonic frequency was 30KHz, and the ultrasonic time was 2.5h. Spherical FOX-7 crystals can be obtained after filtering, washing and drying.

Embodiment 3

[0039] Measure 35 mL of N-methylpyrrolidone and 15 mL of water, weigh 0.01% of the initial amount of FOX-7 additive polyethylene glycol 400, and add it to the crystallization kettle, which is placed in a constant temperature water bath at 35 °C. Add 15.6 g of powdered FOX-7 raw materials into the organic solvent, start the stirrer, and stir at a rate of 100 r / min to completely dissolve FOX-7. Start the dropping device to add water dropwise to the crystallization kettle, and add dropwise while stirring. The stirring rate is 100 r / min, the dropping rate is 2mL / min, and the total amount of water is 180mL. After all the addition was completed, the crystals were ultrasonically treated in the mother liquor, and ultrasonically treated while stirring. The stirring rate was 100 r / min, the ultrasonic frequency was 45KHz, and the ultrasonic time was 2h. Spherical FOX-7 crystals can be obtained after filtering, washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com