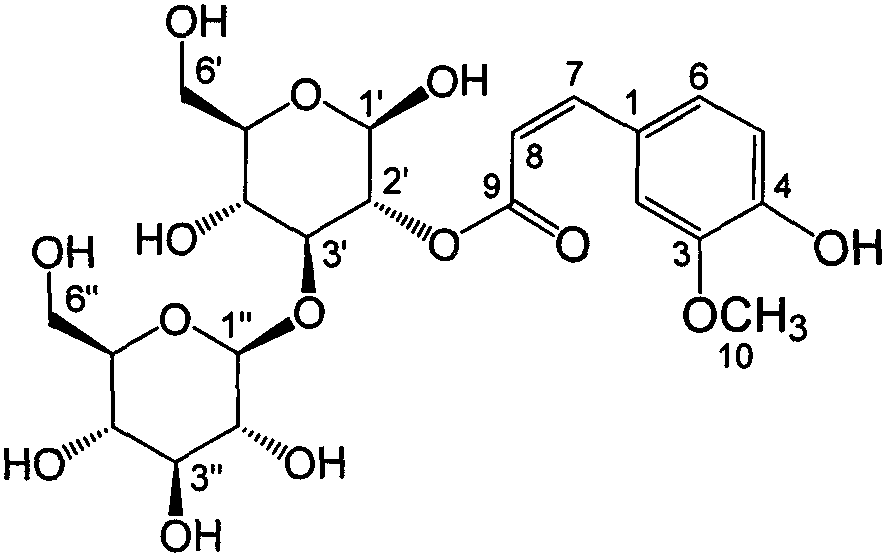

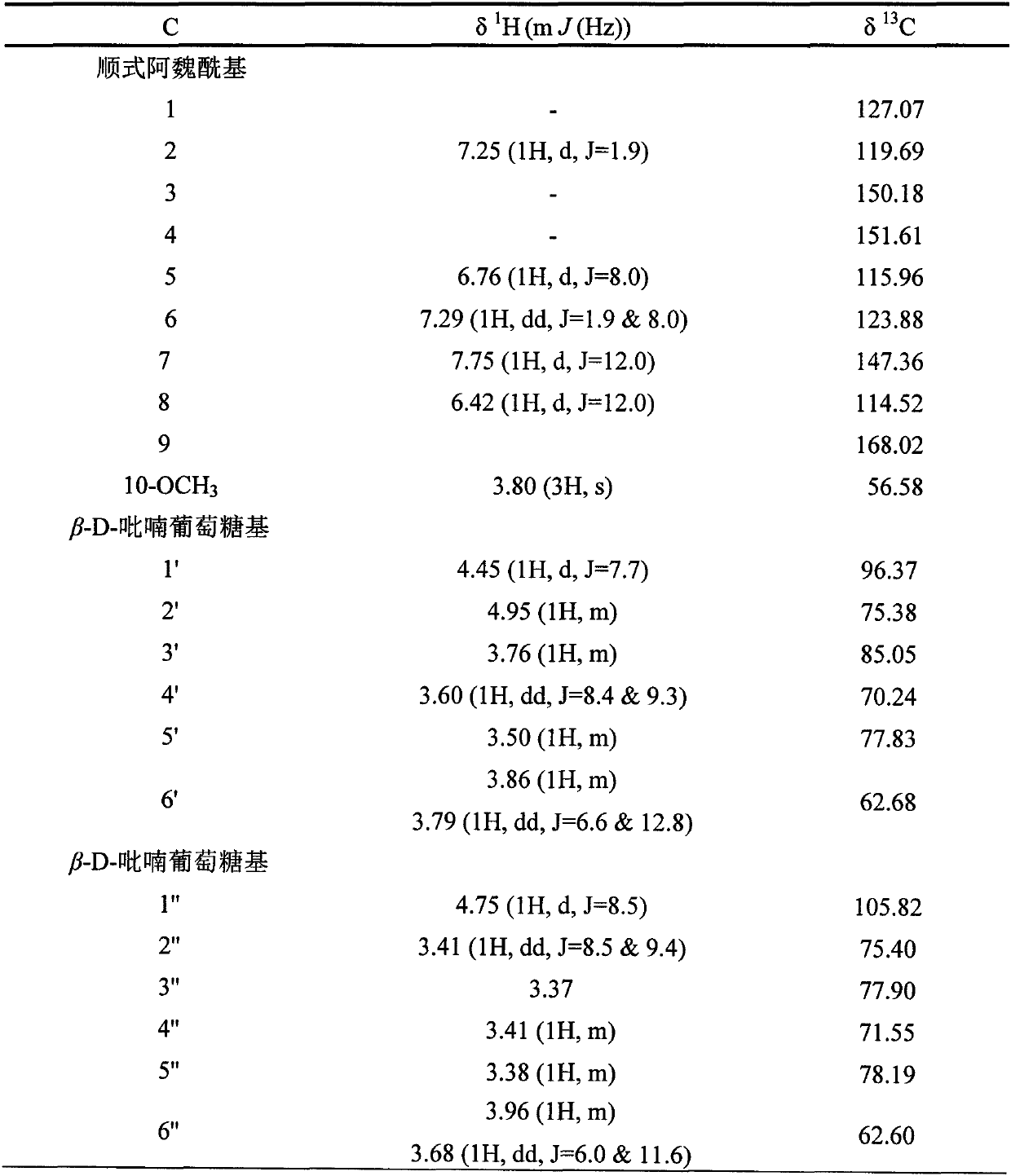

Cis-ferulic acid glycoside in walnut green husk and preparation method thereof

A technology of walnut green husk and ferulic acid, which is applied in the field of comprehensive utilization of high value-added chemical components, can solve problems such as insufficient research, and achieve the effects of efficient preparation process, high product yield, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of 2-O-cis-feruloyl-3-O-β-D-glucopyranose-β-D-glucopyranoside from the walnut green bark of Yangbi walnut tree

[0022] Step 1: get the walnut green skin of the Yangbi walnut tree (Juglans sigillata, another name three Taiwan bubble walnuts, tea bubble walnuts, deep texture bubble walnuts, iron walnuts, etc.) that is cleaned and dried in the shade, and cross 40 mesh sieves after crushing, and the mass ratio is Add 70% methanol aqueous solution at 1:2, extract at room temperature for 3 times, each time for 72 hours, filter, and concentrate the filtrate under reduced pressure to 4% of the original volume to obtain a crude extract;

[0023] Step 2: Add water with 3 times the mass of the crude extract, stir, add petroleum ether with 3 times the mass of the crude extract to extract 4 times, separate the petroleum ether layer, add ethyl acetate with 3 times the mass of the crude extract to the remaining water layer ester extraction 4 times, the ethyl ac...

Embodiment 2

[0032] Example 2: Preparation of 2-O-cis-feruloyl-3-O-β-D-glucopyranose-β-D-glucopyranoside from the walnut green bark of wild walnut tree

[0033] Step 1: Get the walnut green skin of the wild walnut tree (Juglans cathayensis Dode, another name hickory nut, Pakistan walnut etc.) that washes and dry in the shade, pass through 40 mesh sieves after pulverizing, be 1: 3 by mass ratio and add volume percent concentration to be 75 % methanol aqueous solution, ultrasonic-assisted extraction twice, each time for 1 hour, filtered, and the filtrate was concentrated under reduced pressure to 6% of the original volume to obtain a crude extract;

[0034] Step 2: Add water with 2 times the mass of the crude extract, stir, add petroleum ether with 4 times the mass of the crude extract to extract 3 times, separate the petroleum ether layer, add ethyl acetate with 4 times the mass of the crude extract to the remaining water layer The ester was extracted twice, the ethyl acetate layer was sepa...

Embodiment 3

[0037] Example 3: Preparation of 2-O-cis-feruloyl-3-O-β-D-glucopyranose-β-D-glucopyranoside from walnut green bark of walnut tree

[0038] Step 1: get the walnut green skin of the walnut tree (Juglans regia, having another name called Chinese walnut, common walnut etc.) that cleans and dry, cross 40 mesh sieves after pulverizing, be 1: 2.5 by mass ratio and add volume percent concentration and be 65% methanol aqueous solution, heated and extracted 4 times, each time for 12 hours, filtered, and the filtrate was concentrated under reduced pressure to 5% of the original volume to obtain a crude extract;

[0039] Step 2: Add water with 2 times the mass of the crude extract, stir, add petroleum ether with 3 times the mass of the crude extract to extract twice, separate the petroleum ether layer, add ethyl acetate with 3 times the mass of the crude extract to the remaining water layer The ester was extracted twice, the ethyl acetate layer was separated, and the ethyl acetate layer w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com