Silk fibroin solution preparation and identification method

A technology of protein solution and silk fibroin, which is applied in the field of biomedicine, can solve the problems of poor mechanical properties of regenerated silk fibroin materials, and achieve the effect of shortening the time-consuming identification and rapid elution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

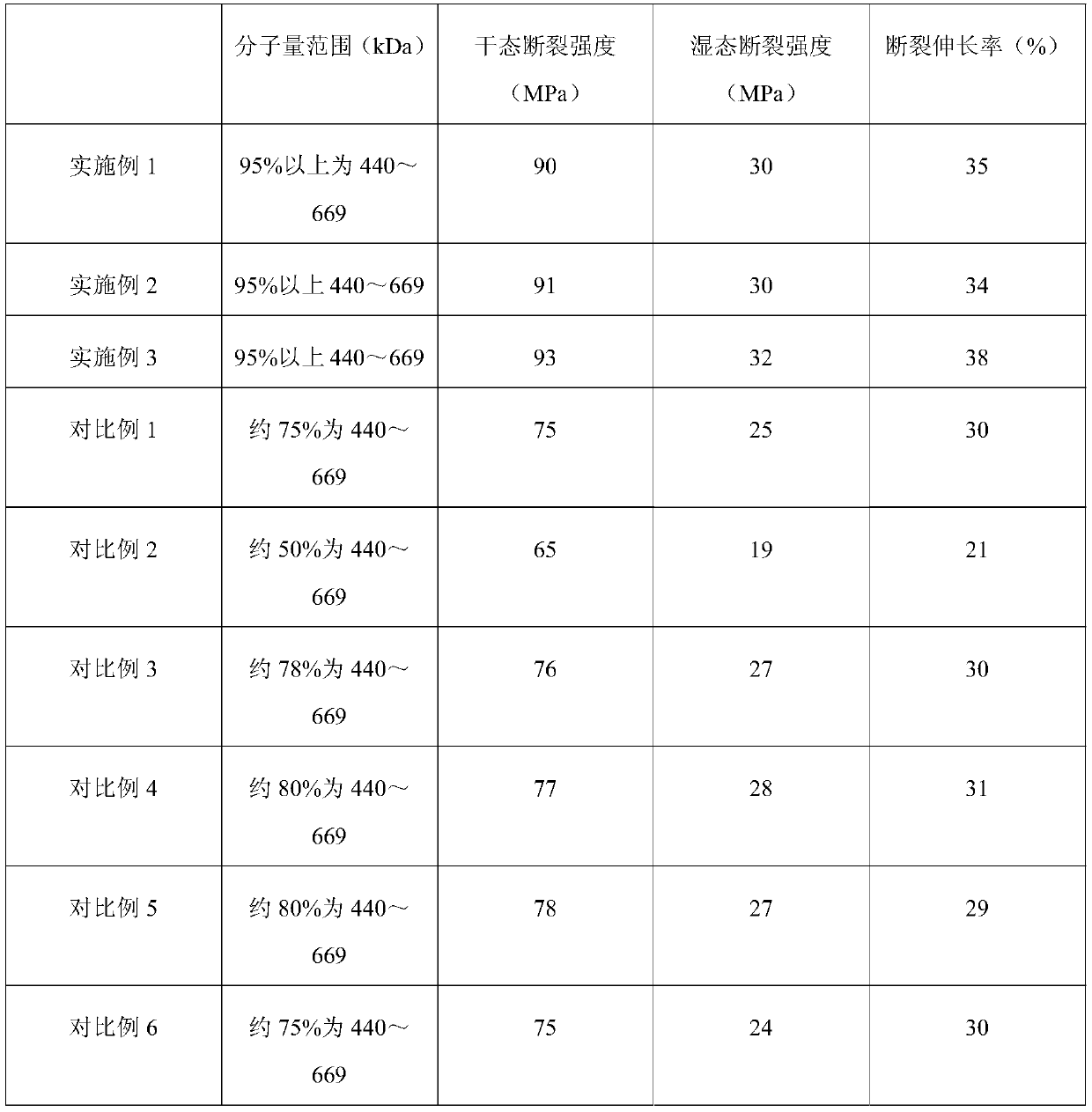

Examples

Embodiment 1

[0029] A method for preparing a silkworm fibroin protein solution, which uses silkworm silk as a raw material, and undergoes the steps of degumming, hydrolysis, impurity removal and sterilization in sequence to obtain the silk fibroin protein solution described above, wherein the specific method of the hydrolysis step yes:

[0030] (1) First mix calcium chloride, sodium thiocyanate, distilled water, 1,2,4-butanetriol, polyethylene glycol 300, and diethylenetriaminepentaacetic acid in a mass ratio of 1:0.5:8:2:5 : 0.8 mixed to obtain the solution, for subsequent use;

[0031] (2) Then the degummed silk obtained after the degumming step is successively subjected to freeze-thaw treatment and microwave treatment;

[0032] (3) Finally, add the silk treated in step (2) into a dissolving solution with 6 times the weight, and treat it for 5 hours under the conditions of 70° C. and 0.6 MPa.

[0033] The specific method of degumming treatment is as follows: soak silk in 0.5% sodium ca...

Embodiment 2

[0044] A method for preparing a silkworm fibroin protein solution, which uses silkworm silk as a raw material, and undergoes the steps of degumming, hydrolysis, impurity removal and sterilization in sequence to obtain the silk fibroin protein solution described above, wherein the specific method of the hydrolysis step yes:

[0045] (1) First, calcium chloride, sodium thiocyanate, distilled water, 1,2,4-butanetriol, polyethylene glycol 300, and diethylenetriaminepentaacetic acid are mixed in a mass ratio of 1:0.6:6:3:4 : 1 mixed to obtain a solution, for subsequent use;

[0046] (2) Then the degummed silk obtained after the degumming step is successively subjected to freeze-thaw treatment and microwave treatment;

[0047] (3) Finally, add the silk treated in step (2) into a 4-fold weight solution, and treat it for 8 hours at 80° C. and 0.5 MPa.

[0048] The specific method of degumming treatment is: soak the silk in 1% sodium carbonate aqueous solution with a mass concentrati...

Embodiment 3

[0059] A method for preparing a silkworm fibroin protein solution, which uses silkworm silk as a raw material, and undergoes the steps of degumming, hydrolysis, impurity removal and sterilization in sequence to obtain the silk fibroin protein solution described above, wherein the specific method of the hydrolysis step yes:

[0060] (1) First, calcium chloride, sodium thiocyanate, distilled water, 1,2,4-butanetriol, polyethylene glycol 300, and diethylenetriaminepentaacetic acid are mixed in a mass ratio of 1:0.55:7:2.5:4.5 : 0.9 mixed to obtain a solution, for subsequent use;

[0061] (2) Then the degummed silk obtained after the degumming step is successively subjected to freeze-thaw treatment and microwave treatment;

[0062] (3) Finally, add the silk treated in the step (2) into a dissolving solution with 5 times the weight, and treat it for 6 hours under the conditions of 75° C. and 0.55 MPa.

[0063] The specific method of degumming treatment is: immerse silk in 0.8% so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com