Nano composite material and preparation method thereof

A nanocomposite material and self-healing technology, applied in the field of nanocomposite materials and their preparation, can solve problems such as low self-repairing efficiency and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

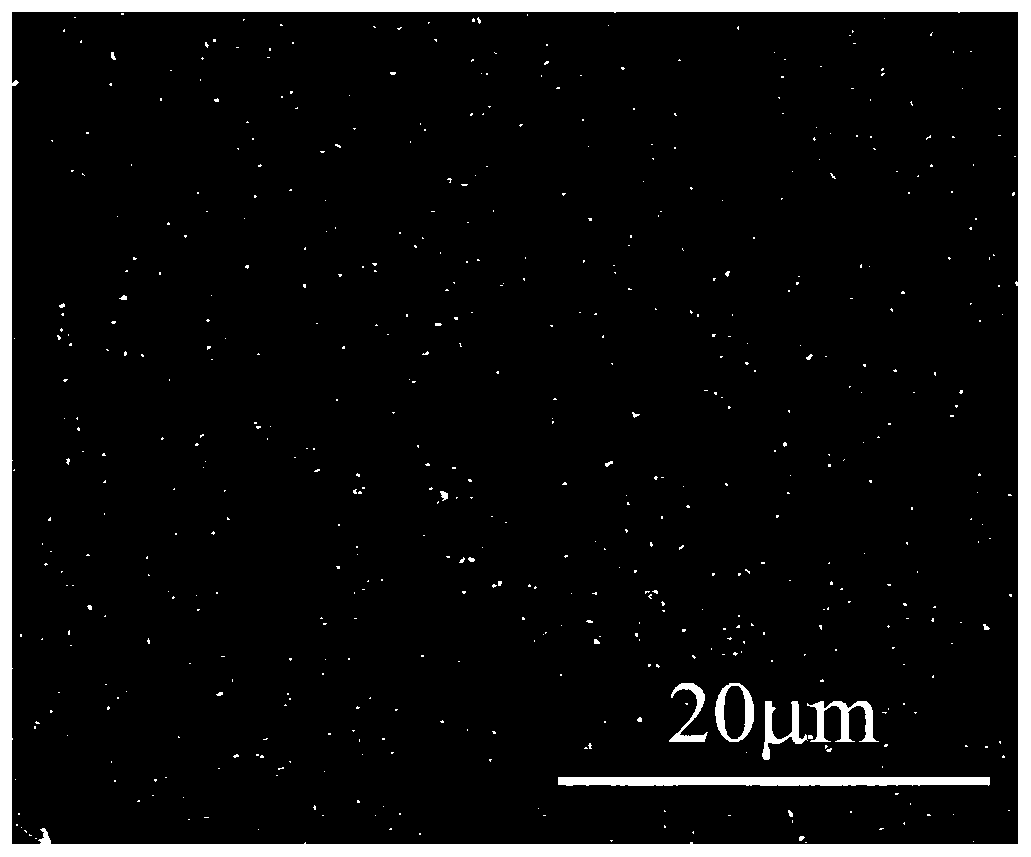

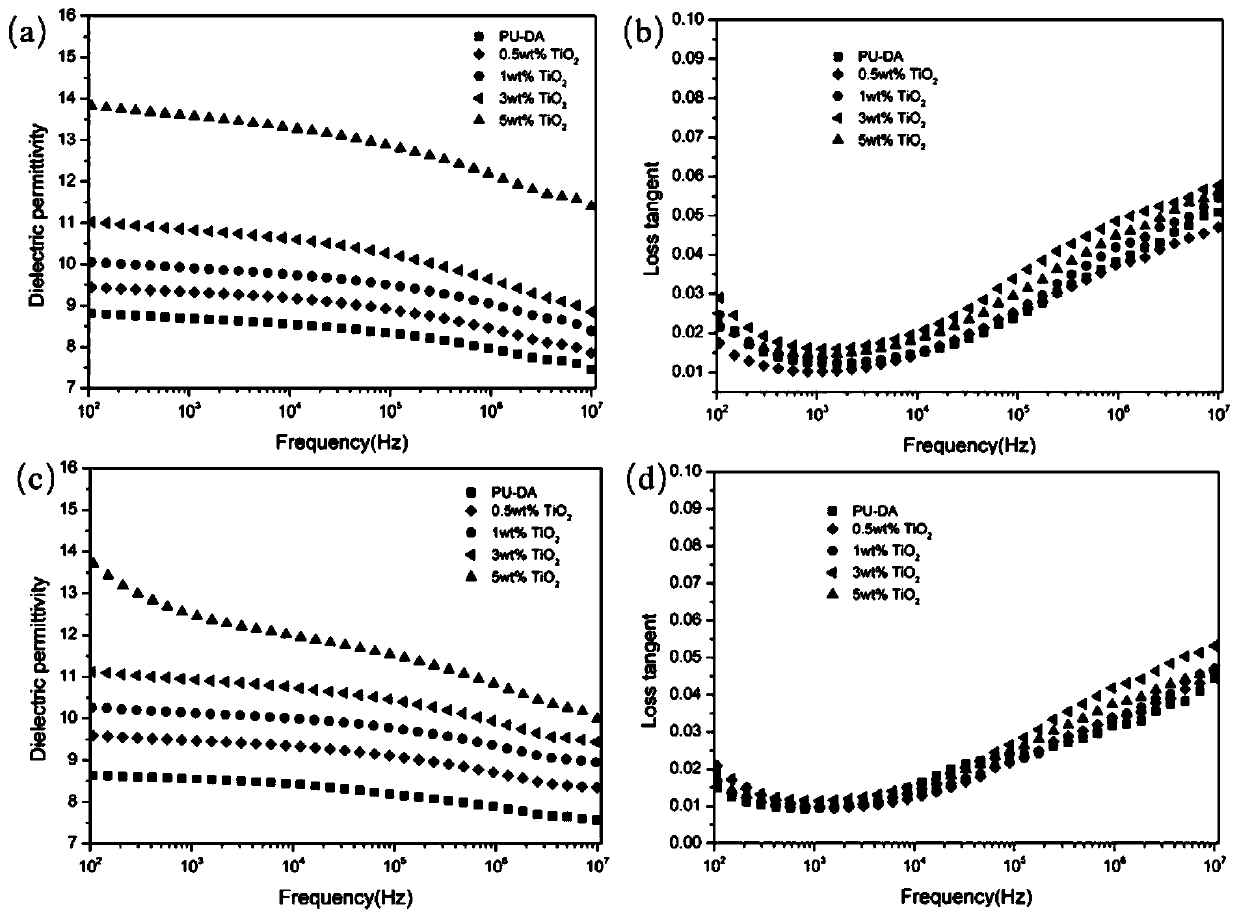

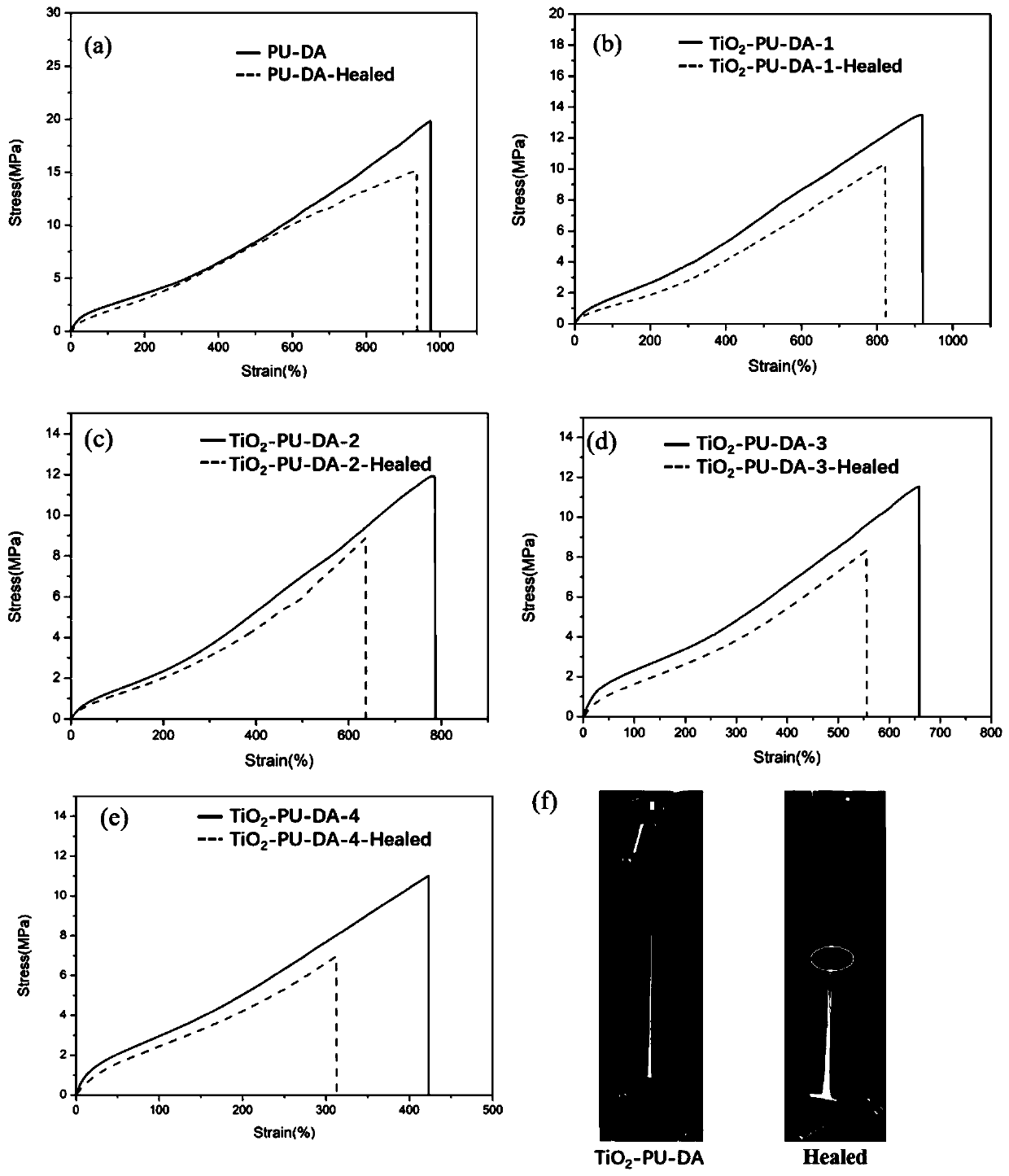

Image

Examples

Embodiment 1

[0057] Step 1: Under the protection of an inert atmosphere, the molecular weight of 2000g mol -1 Hydroxyl-terminated polytetrahydrofuran (4.0 g) and N,N-dimethylformamide (DMF) (15 g) were thoroughly mixed, and the mixed solution was added into a three-necked flask at room temperature.

[0058] Step 2: Under the protection of an inert atmosphere, diphenylmethane diisocyanate (MDI) (1.050 g) and DMF (10 g) were mixed at room temperature.

[0059] Step 3: Under the protection of an inert atmosphere, add the mixed solution in Step 2 to the mixed solution in Step 1 through an atmospheric funnel. Reaction was carried out at 80° C. for 3 h under a nitrogen atmosphere.

[0060] Step 4: Under the protection of an inert atmosphere, 0.75g of bismaleimide (BMI) and 0.40g of furfuryl alcohol (FA) were mixed with 9.6g of DMF, and heated in an oven at 70° C. for 3 hours to obtain the repaired part.

[0061] Step 5: under the protection of an inert atmosphere, add the repaired part as a ch...

Embodiment 2

[0069] Step 1: Under the protection of an inert atmosphere, the molecular weight of 2000g mol -1 Hydroxyl-terminated polytetrahydrofuran (2.0 g) and N,N-dimethylformamide (DMF) (7.5 g) were thoroughly mixed, and the mixed solution was added into a three-necked flask at room temperature.

[0070] Step 2: Under the protection of an inert atmosphere, diphenylmethane diisocyanate (MDI) (0.500 g) and DMF (5.0 g) were mixed at room temperature.

[0071] Step 3: Under the protection of an inert atmosphere, add the mixed solution in Step 2 to the mixed solution in Step 1 through an atmospheric funnel. React at 85°C for 2h under nitrogen atmosphere.

[0072] Step 4: Under the protection of an inert atmosphere, 0.375g of bismaleimide (BMI) and 0.20g of furfuryl alcohol (FA) were mixed with 4.8g of DMF, and heated in an oven at 70° C. for 3 hours to obtain the repaired part.

[0073] Step 5: Under the protection of an inert atmosphere, add the repaired part as a chain extender to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com