A color-developing paint for inspecting fuel spillage from aircraft during flight

A technology for flight process and fuel, applied in the field of coatings, which can solve problems such as poor adhesion, difficult color rendering, and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A color-developing paint used to inspect fuel spillage during aircraft flight, the specific components and dosage are shown in Table 1.

[0040] Table 1 embodiment 1 concrete composition and consumption

[0041] serial number raw material weight Remark 1 rosin 42 oil soluble resin 2 Butyl acetate 20 solvent 3 Cyclohexane 16 solvent 4 acetone 6 solvent 5 10-Phenanthrenequinone 0.4 Fluorescent reagent 6 9-fluorenone 0.5 Fluorescent reagent 7 BYK333 0.3 Wetting and leveling agent 8 SN4333 0.2 Wetting and leveling agent 9 Tego410 0.1 Toughener 10 Dioctyl phthalate 9 Toughener 11 Dibutyl phthalate 5.5 Toughener

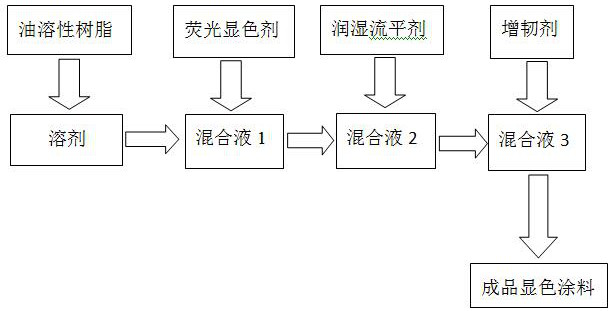

[0042] like figure 1 Shown, the preparation method steps of the color-developing paint that are used to test the fuel oil spilled during the flight of the aircraft are as follows:

[0043] Step 1: Add 42 parts of rosin to a mixed solvent consisting...

Embodiment 2

[0056] A color-developing paint used to inspect fuel spillage during aircraft flight, the specific components and dosage are shown in Table 3.

[0057] Table 1 embodiment 2 specific composition and consumption

[0058] serial number raw material weight Remark 1 Alkyd resin 40.4 oil soluble resin 2 Xylene 30 solvent 3 Cyclohexane 12 solvent 4 Butyl acetate 6.4 solvent 5 9-fluorenone 0.5 Fluorescent reagent 6 10-Phenanthrenequinone 0.3 Fluorescent reagent 7 BYK310 0.3 Wetting and leveling agent 8 BYK333 0.1 Wetting and leveling agent 9 Dioctyl phthalate 2 Toughener 10 Diisononyl adipate 8 Toughener

[0059] like figure 1 Shown, the preparation method steps of the color-developing paint that are used to test the fuel oil spilled during the flight of the aircraft are as follows:

[0060] Step 1, add 40.4 parts of alkyd resin to a mixed solvent consisting of 30 parts of xy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com