Bioconversion method for producing 1,5-pentanediamine

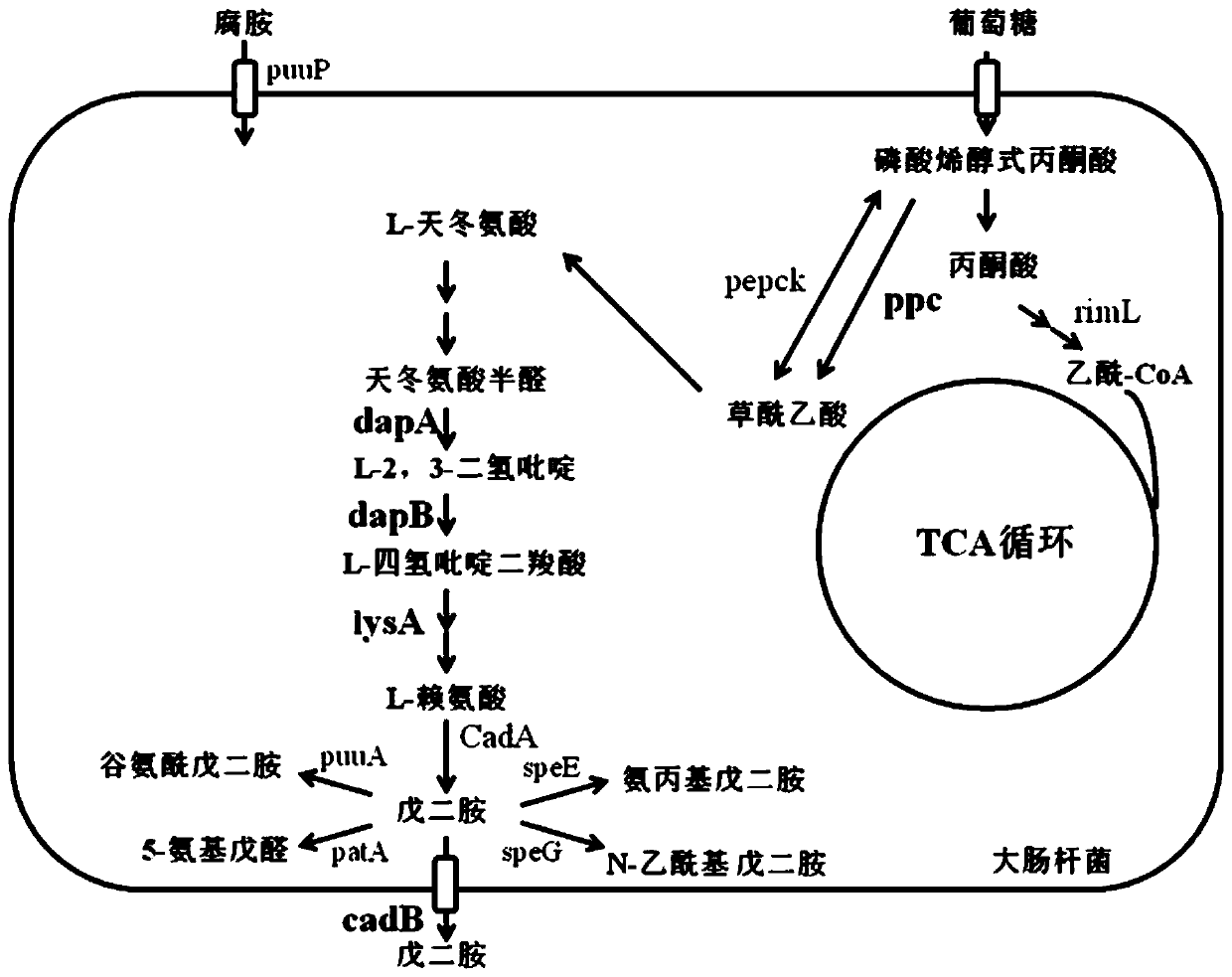

A technology for biotransformation and pentamethylenediamine, which is applied in the field of genetic engineering, can solve the problems of long fermentation period, complex metabolic regulation and low efficiency, and achieve the effects of saving production costs, promoting production fermentation, and improving the utilization rate of carbon sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

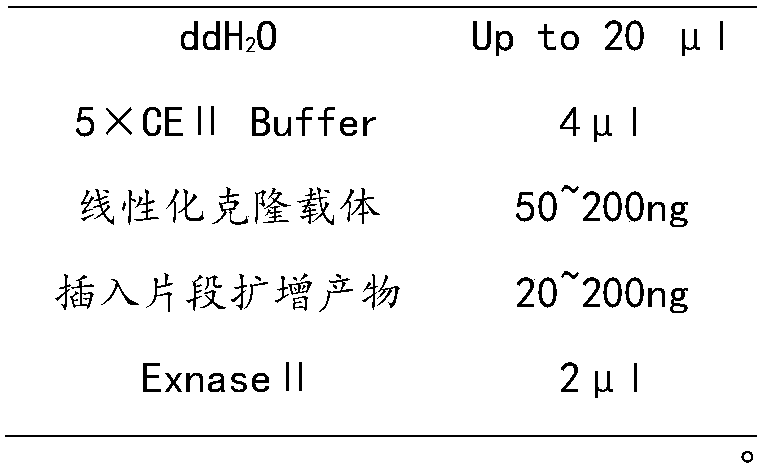

[0045] (3) Preparation of electroporation competent

[0046] The plasmid Pcas was transferred into 1,5-pentanediamine-producing strain DFC1001 competent cells, and a single colony was picked and inoculated in 5 mL of LB liquid medium, cultured at 30°C, 200 rpm, for 8 hours. Transfer to 50mL LB liquid medium containing 1% inoculum and cultivate to OD 600 About 0.2, add 1.5mL 1mM L-arabinose solution, continue to cultivate to OD 600 0.4 to 0.5; then transferred to a 50mL centrifuge tube for 20 minutes on ice to stop growth. 4°C, 4000rpm, centrifuge for 10min, and collect the bacteria. Wash the cells with 40 mL of pre-cooled sterile water, and collect the cells by centrifugation. Repeat the above steps; wash the cells with 20 mL of pre-cooled 10% glycerol, and collect the cells by centrifugation. Finally, 500 μL of pre-cooled 10% glycerol was used to resuspend the bacterial cells, and the obtained NT1003-cas competent cells were allocated for use;

[0047] (4) Gene knockout ...

Embodiment 1

[0052] Example 1 Knockout of the 1,5-pentanediamine degradation pathway of the production strain

[0053] 1. Knockout of degradation genes

[0054] The sgRNA and homology arms of the four degradation genes puuA, speE, speG and patA were constructed respectively. See Table 2 and Table 3 for primers. The plasmid sg-X and X fragments were transferred into DFC1001-cas competent cells by electroporation, cultured at 30°C, 200rpm for 2h, and coated with 40μg·mL -1 Streptomycin resistance and 50 μg mL -1 Culture overnight at 30°C on kanamycin-resistant LB plates. The colonies in the plate were screened by means of colony PCR, and the PCR primers were X-F1 / X-R2. Three of the positive clones were selected for sequencing, and the correctly sequenced strains were stored in a -80°C refrigerator for later use.

[0055] Table 2 sgRNA-puuA, speE, speG and patA primers

[0056]

[0057] Table 3 PuuA, speE, speG and patA homology arm primers

[0058]

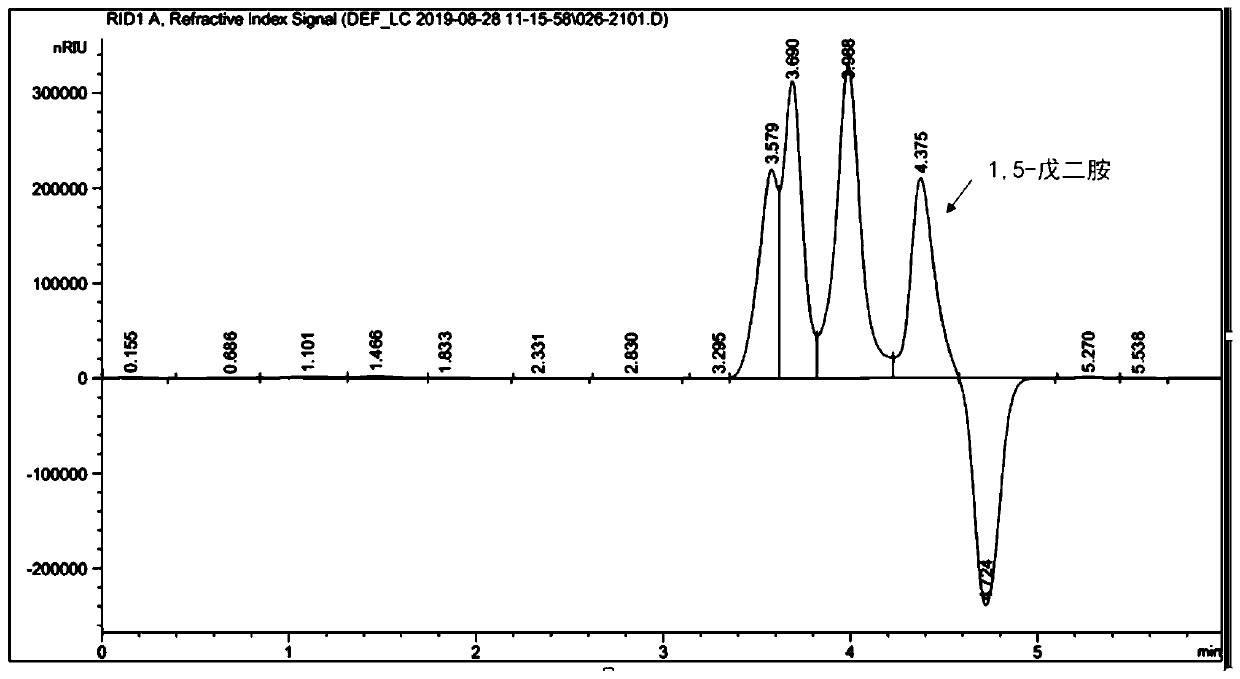

[0059] 2. Fermentation verif...

Embodiment 2

[0064] Example 2 The increase of the production strain 1,5-pentanediamine synthesis precursor lysine

[0065] On the basis of the modified strain in Example 1, the transformation was continued, and the production was further increased by increasing the synthesis of lysine, the precursor of 1,5-pentanediamine synthesis. The specific steps are as follows:

[0066] 1. Knockout of lysine synthesis inhibitory pathway

[0067]The sgRNA and homology arms of pepck and rimL genes were constructed respectively. See Table 4 and Table 5 for primers. The plasmid sg-X and X fragments were transferred into DFC1001-cas competent cells by electroporation, cultured at 30°C, 200rpm for 2h, and coated with 40μg·mL -1 Streptomycin resistance and 50 μg mL -1 Culture overnight at 30°C on kanamycin-resistant LB plates. The colonies in the plate were screened by means of colony PCR, and the PCR primers were X-F1 / X-R2. Three of the positive clones were selected for sequencing, and the correctly se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com