Method for preparing composite-layer nonwoven fabric

A non-woven, composite layer technology, applied in the direction of coating, textile and papermaking, metal material coating process, etc., can solve the problem of high application cost, and achieve the effect of reducing application cost, cost reduction, and excellent sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

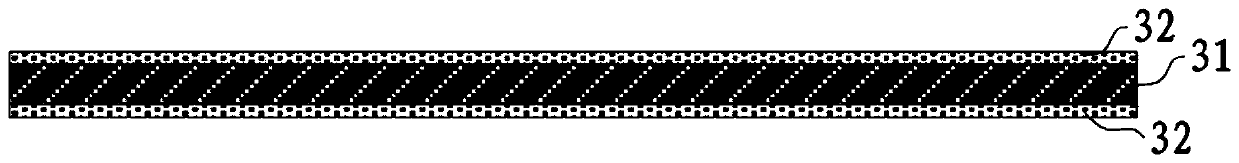

[0040] This implementation provides a composite layer non-woven fabric, which includes a non-woven fabric base layer and a calcium hydroxide particle coating layer bonded to at least one side of the non-woven fabric base layer. Calcium hydroxide granules have strong bactericidal and antibacterial effects. Calcium hydroxide granules can strongly destroy the protease in the bacteria, make the protease lose its activity, and cause the bacteria to die. After the bacteria are killed by the calcium hydroxide particles, they are then contacted with other bacterial colonies, and the above process is repeated repeatedly to achieve continuous sterilization and antibacterial. Therefore, in this embodiment, one or both sides of the non-woven base layer are coated with calcium hydroxide particles, which can kill bacteria and viruses gathered on the surface, and have excellent bactericidal and antibacterial effects. At the same time, the paper diapers, sanitary napkins, panty liners, wet wi...

Embodiment 2

[0053] This example is described in a manner of extracting calcium hydroxide particles from animal calcium sources.

[0054] Calcium hydroxide particles pass through in the present embodiment Figure 4 Prepared by the following method shown:

[0055] S401: Washing the animal calcium source.

[0056] At least one of the animal calcium sources in this embodiment: scallop shells, abalone shells, conch shells, surf clam shells, sea urchin shells, coral shells and egg shells. In this embodiment, ultrasonic cleaning may be used to clean the animal calcium source, or other effective cleaning methods, such as washing with water, may be used.

[0057] S402: Perform multi-stage high-temperature calcination on the washed animal calcium source.

[0058] In this embodiment, continuous multi-stage high-temperature calcination can be carried out on the cleaned animal calcium source, for example, continuous eight-stage high-temperature calcination can be carried out. The specific calcinati...

Embodiment 3

[0065] This embodiment provides a kind of composite layer non-woven fabric preparation method, please refer to Figure 5 shown, including:

[0066] S501: Prepare a non-woven fabric base layer.

[0067] The preparation method of the non-woven fabric base layer in this embodiment can adopt any manner of non-woven fabric base layer, which will not be repeated here.

[0068] S502: Coating calcium hydroxide particle coating on at least one side of the non-woven fabric base layer.

[0069] In this step, the calcium hydroxide particle coating is composed of natural grade calcium hydroxide particles, and the thickness of the calcium hydroxide particle coating can be 10 nanometers to 100 nanometers. Of course, the specific thickness can be flexibly set according to actual needs.

[0070] In S502, plating calcium hydroxide particle coating on at least one side of the non-woven fabric base layer includes:

[0071] Calcium hydroxide particle coating is coated on the front or back of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com