Mechanoluminescence guardrail net and preparation process thereof

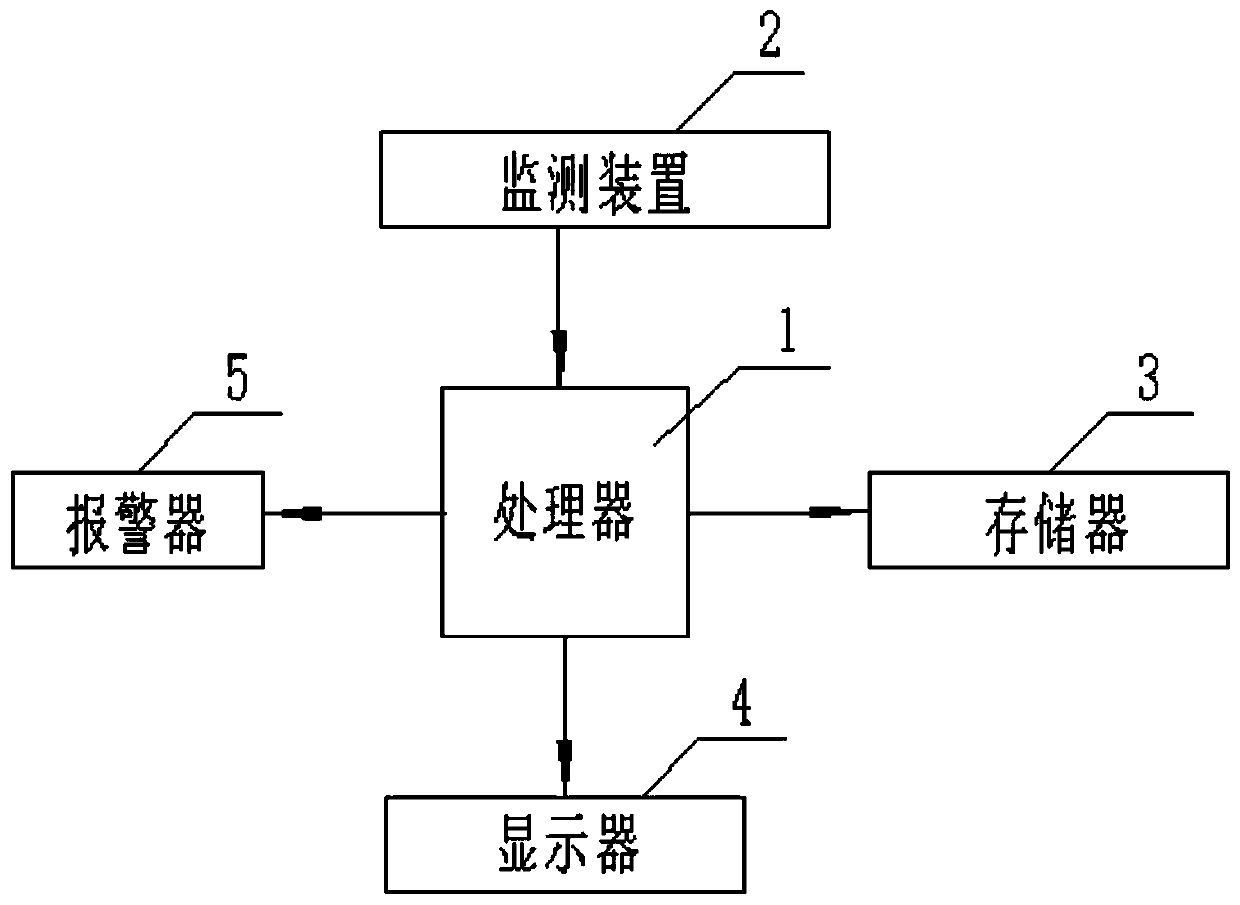

A preparation process and luminescence technology, applied in the field of fence nets, can solve the problems of inability to play an edge warning function, troublesome fence monitoring and maintenance, invisible fence nets at night, etc. performance, the effect of improving monitoring sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] like Figure 1-3 As shown, a kind of mechanoluminescence guardrail net, comprises metal net 6, long afterglow electroluminescence material, and described long afterglow electroluminescence material is covered on the surface of metal net 6; Described metal net 6 is grid shape; The long afterglow electroluminescent material uses strontium aluminate as the host material, Eu 2+ 、Dy 3+ electron doping.

[0051] The metal mesh 6 is barbed wire; electron-doped Eu 2+ 、Dy 3+ The final strontium aluminate is used as a long-lasting electroluminescent material, which is in powder form; the long-lasting electroluminescent material is waterproofed with pyrophosphoric acid; The material is added to pyrophosphoric acid, and the mass ratio of the luminescent material to pyrophosphoric acid is (0.8-1.2):(1.10-1.40); the luminescent material modified by superpyrophosphoric acid is in powder form.

[0052] The specific surface area S of the powdery luminescent material is 400-780m 2 ...

Embodiment 2

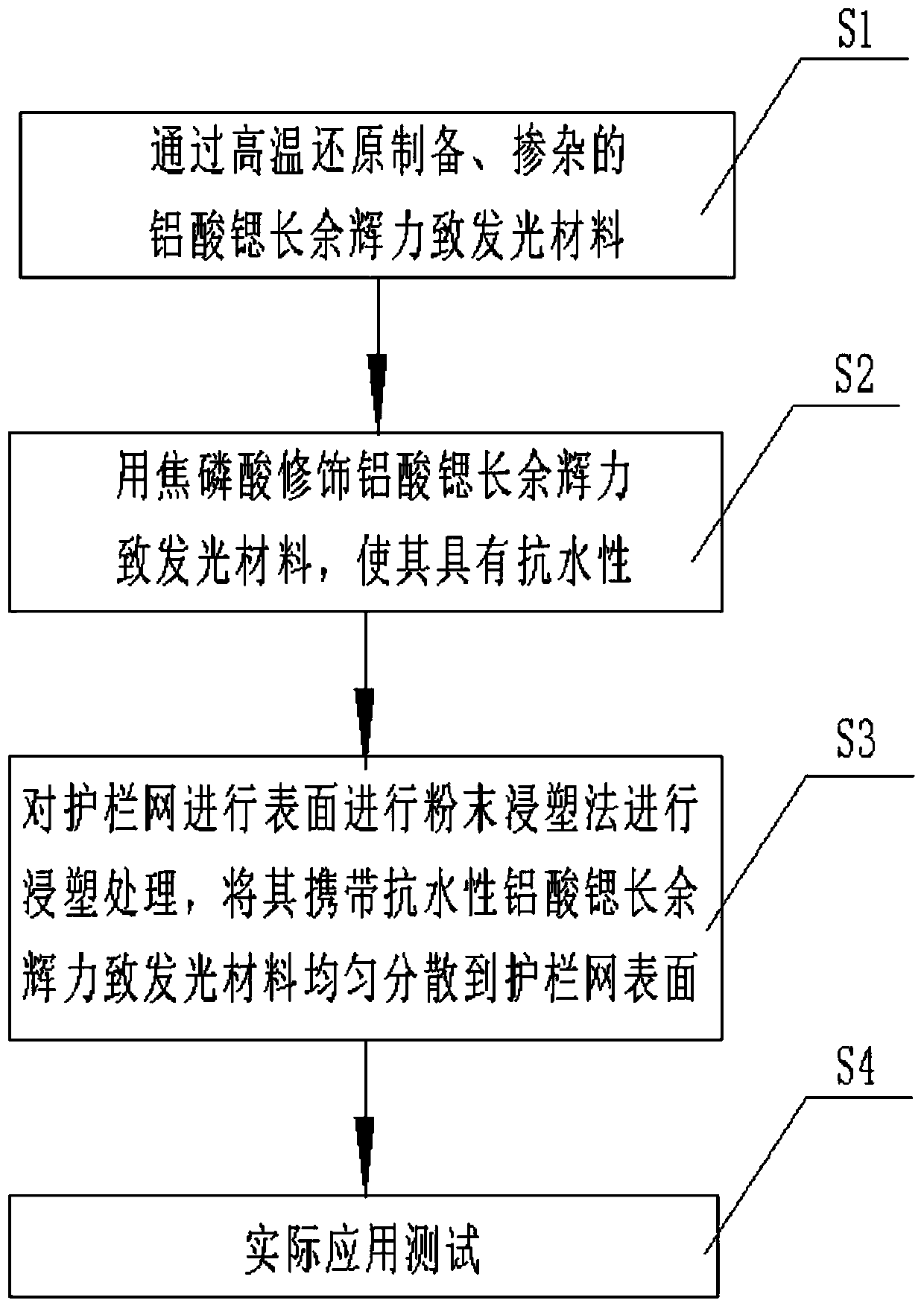

[0058] The present invention also provides a preparation process of the mechanoluminescence fence net, the preparation process comprises steps:

[0059] S1. Preparation of Eu by high temperature reduction 2+ 、Dy 3+ doped strontium aluminate;

[0060] S2. Modifying strontium aluminate long-lasting electroluminescent material with pyrophosphoric acid, so that it not only has luminous performance, but also has water resistance;

[0061] S3. Perform dipping treatment on the surface of the metal mesh 6, and then uniformly disperse the water-resistant modified long-lasting mechanoluminescent material on the surface of the metal mesh 6 to obtain a mechanoluminescent fence net.

[0062] In the step S1, materials for preparing strontium aluminate include: aluminum nitrate, strontium nitrate, europium oxide, and dysprosium oxide.

[0063] In the step S1, the reducing gas used for preparing strontium aluminate is hydrogen, and the protective gas is nitrogen.

[0064] In the step S2, ...

Embodiment 3

[0077] In the step S2, the strontium aluminate long-lasting electroluminescence material, pyrophosphoric acid, and dimethylformamide are dispersed in dimethylformamide at a mass ratio of 0.8:1.10:450, and after ultrasonic dispersion for 15 minutes, the Stir vigorously in the pot at 60 degrees Celsius for 10 hours to obtain a pyrophosphate-modified strontium aluminate long-lasting electroluminescent material, which improves its anti-hydrolysis performance and prolongs its service life.

[0078] In the step S3, a powder dipping method is used in the dipping treatment.

[0079] The pyrophosphoric acid-modified strontium aluminate long afterglow electroluminescent material was repeatedly washed twice with dimethylformamide and tetrahydrofuran, and then dried at 100 degrees Celsius to obtain the pyrophosphate-modified water-resistant strontium aluminate long afterglow Mechanoluminescent materials.

[0080] In the step S3, the water-resistant strontium aluminate long-lasting electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com