Expandable microsphere drying system and method for drying by using same

A technology of drying system and expanded microspheres, which is applied in chemical instruments and methods, drying solid materials, and drying solid materials without heating, etc. It can solve the problems of high heat transfer loss, large space occupied by equipment, and long drying time, etc., to achieve Improve the reliability and simplicity of use, low cost, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

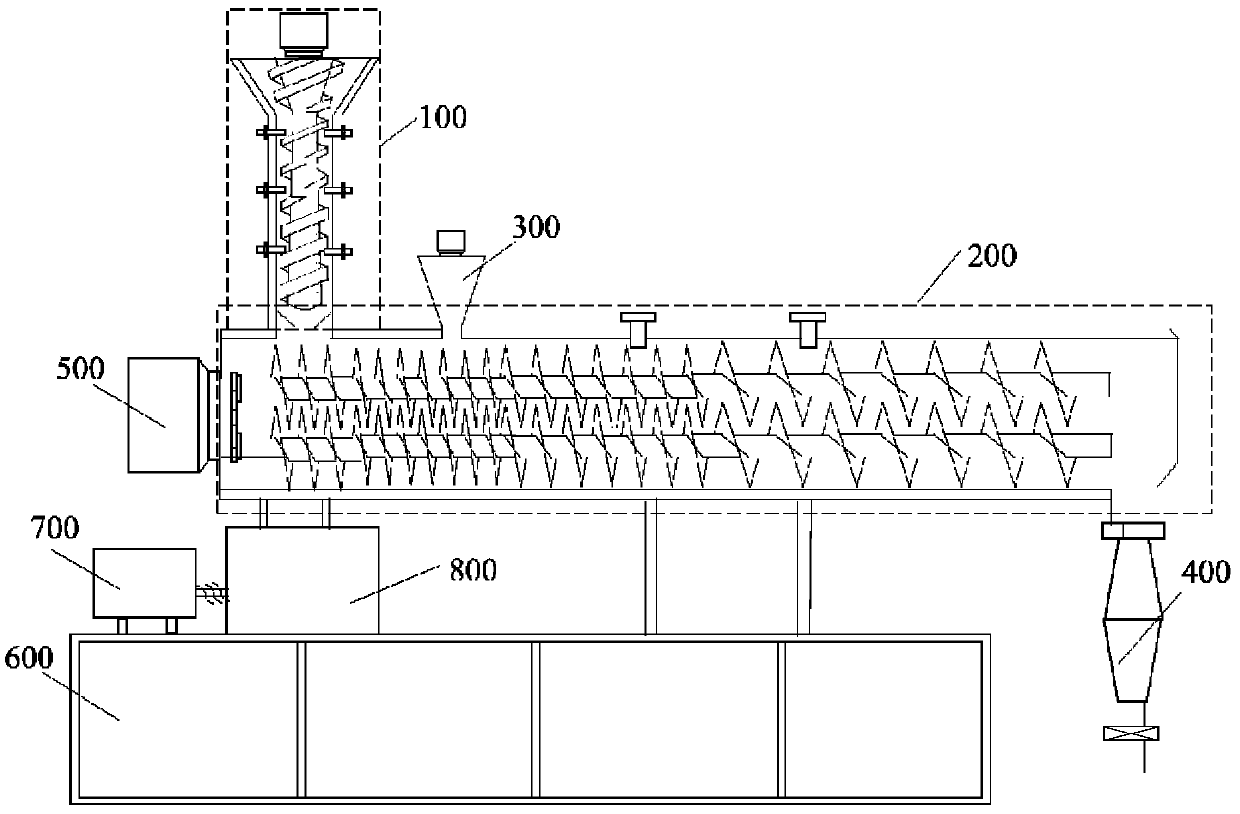

[0132] use figure 1 Shown drying system implements the method of the present embodiment, and described method comprises the steps:

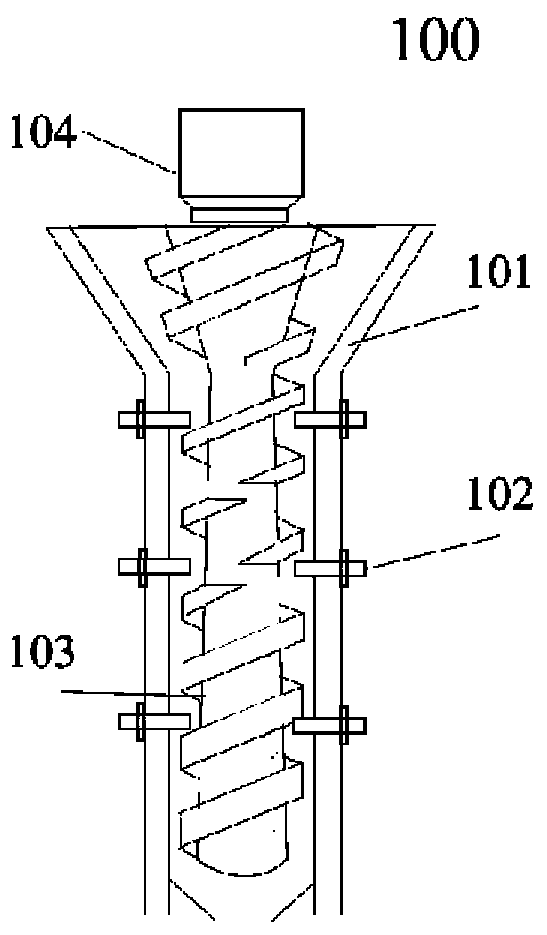

[0133] (1) First, add the compound synthesized by suspension polymerization into the conical hopper 101 of the solid-liquid separation device 100 (self-made, wherein the conical hopper 101 is from Hongyu Machinery Co., Ltd., and the dehydration screw 103 is from Zhoushan Bohai Machinery Co., Ltd.). The microsphere slurry with a water content of 70% (wherein the microspheres are low-temperature microspheres), the feeding speed is 300kg / h.

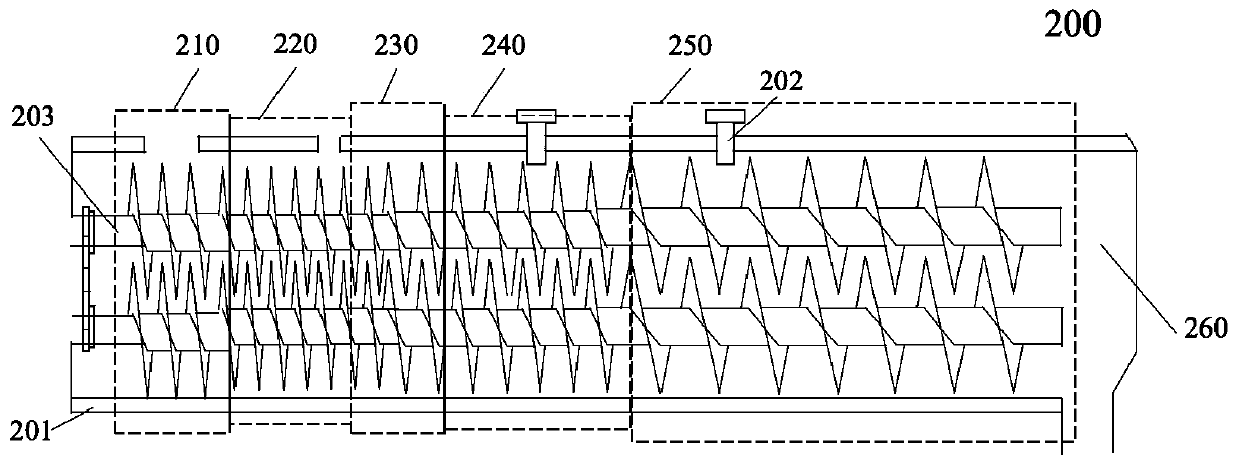

[0134] In the solid-liquid separation device 100, the driving motor 104 drives the dewatering screw 103 to rotate, thereby realizing the solid-liquid separation of the slurry, wherein the liquid is removed from the water outlet 102, and the dewatering screw 103 pushes the solid (microsphere wet cake) To the feeding section 210 of the drying device 200 (from Shanghai Baodie Plastic Equipment Co., Ltd., which is...

Embodiment 2

[0142] The drying system and process flow of embodiment 2 are basically the same as embodiment 1, except the following aspects:

[0143] In step (1), the microsphere slurry (wherein the microspheres are low-temperature microspheres) with a water content of 70% synthesized by suspension polymerization is added into the conical feeding hopper, and the feeding speed is 350kg / h, and the dehydration screw The 103 revs at 300rpm.

[0144] In step (2), the processing aid from the additive adding device 300 is a liquid dispersant polyvinylpyrrolidone (Shanghai Aladdin Biochemical Technology Co., Ltd.), and the addition amount is 1Kg / h;

[0145] The rotation speed of the transverse coupling 500 connected with the drying device 200 is 80rpm.

[0146] In step (3), the temperature of the preheating section is 90°C, and the temperature of the drying section is 100°C.

[0147] The microsphere dry powder obtained in step (3) is a dry expandable microsphere powder with a density of 21 kg / m3...

experiment example 1

[0148] The water content test of experimental example 1 microsphere

[0149] Weigh each 100g of the microspheres obtained after drying in Examples 1-2, then place it in an oven at 50°C (Guangzhou Kangnuo Pharmaceutical Machinery Co., Ltd.) to continue drying the water, and weigh the mass once every hour. Until the quality of the microspheres in the beaker no longer changes. To calculate the water content, the calculation formula is as follows:

[0150]

[0151] —Moisture content of microspheres after drying

[0152] m 0 — the mass of the microspheres before being placed in the oven

[0153] m 1 —The mass of the microspheres whose mass does not change after being placed in the oven

[0154] The calculation results are shown in Table 1 below.

[0155]

[0156] It can be seen from the above experimental results that the microsphere slurries with different water contents are dried in the above manner, and the water content of the dried microspheres is between 0.38% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com