A Short-cut Nitrification-ANAMMOX Process for Efficiently Treating Low-Carbon and High-Ammonia Nitrogen Wastewater

A technology of anaerobic ammonium oxidation and short-range nitrification, which is applied in the field of sewage treatment, can solve the problems of low-carbon high-ammonia-nitrogen wastewater and other problems, and achieve the effect of low treatment cost, controllable process and complete denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

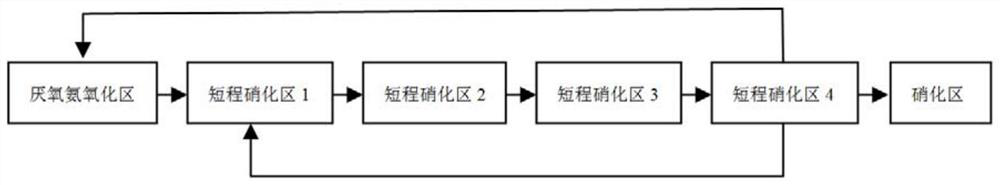

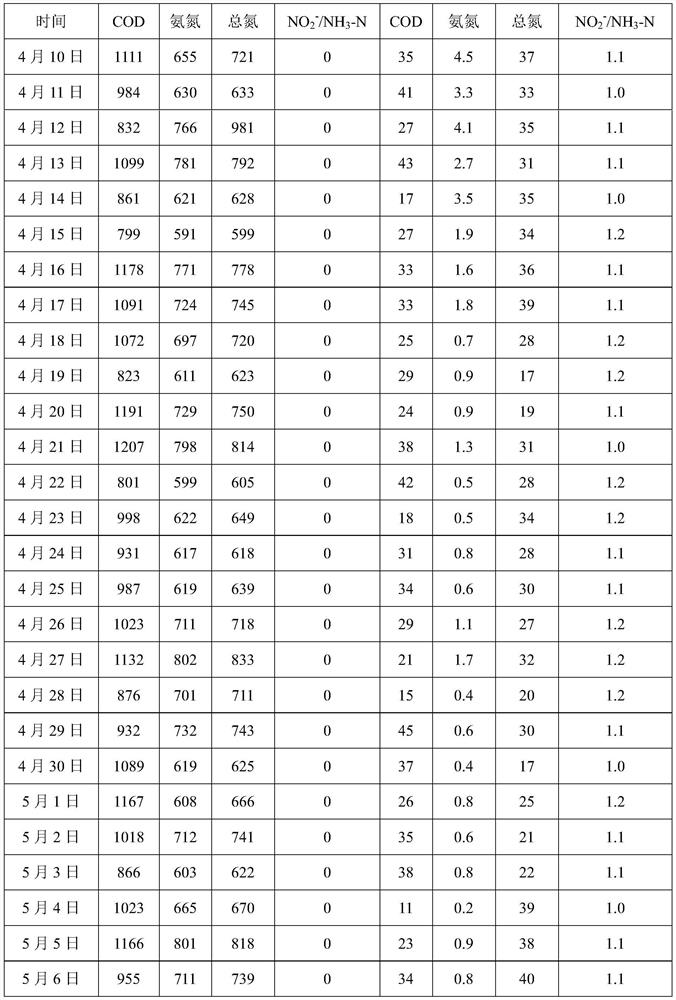

[0040] Such as figure 1 As shown, it is a schematic flow chart of the sewage treatment process for treating low-carbon high-ammonia-nitrogen wastewater in this embodiment. First, the low-carbon and high-ammonia-nitrogen wastewater enters the anammox zone for anammox, and then enters the short-cut nitrification zone 1-4 in turn through the overflow method. A part of the ammonia nitrogen in the wastewater will be converted into nitrite nitrogen in the facultative zone because of the short-cut nitrification The conditions of zones 1-4 are different, and the nitrite nitrogen in the short-range nitrification zone 4 will be higher, which is harmful to the microorganisms in the water body. Therefore, part of the short-range nitrification zone 4 is returned to the short-range nitrification zone 1, and the other part of the wastewater is returned to the anammox. Zone re-reacts until the ratio of nitrite nitrogen to ammonia nitrogen in the short-range nitrification zone 4 is roughly 1.0...

Embodiment 2

[0050] The treatment device is the same as in Example 1, wherein the packing density in the anaerobic ammonium oxidation zone is 0.985g / cm 3 , the filling rate is 30%; the packing density of each short-range nitrification zone is 0.978g / cm 3 , the filling rate is 20%; the packing density in the nitrification zone is 0.97g / cm 3 , fill rate 30%. Control the dissolved oxygen concentration in the anaerobic ammonium oxidation zone to 0.1mg / L, the dissolved oxygen concentration in the short-cut nitrification zone 1 to 0.3mg / L, the dissolved oxygen concentration in the short-cut nitrification zone 2 to 0.5mg / L, and the dissolved oxygen concentration in the short-cut nitrification zone 3 The dissolved oxygen concentration in the short-cut nitrification zone 4 is 1.0mg / L, and the dissolved oxygen concentration in the nitrification zone is 3.0mg / L.

[0051] The anaerobic ammonium oxidation zone, each short-range nitrification zone, and the nitrification zone are inoculated with activa...

Embodiment 3

[0058] The treatment device is the same as in Example 1, wherein the packing density in the anaerobic ammonium oxidation zone is 0.99g / cm 3 , the filling rate is 30%; the packing density of each short-range nitrification zone is 0.98g / cm 3 , the filling rate is 20%; the packing density in the nitrification zone is 0.99g / cm 3 , fill rate 30%. Control the dissolved oxygen concentration in the anammox zone to 0.01mg / L, the dissolved oxygen concentration in the short-cut nitrification zone 1 to 0.3mg / L, the dissolved oxygen concentration in the short-cut nitrification zone 2 to 0.4mg / L, and the dissolved oxygen concentration in the short-cut nitrification zone 3 The dissolved oxygen concentration in the short-cut nitrification zone 4 is 0.7mg / L, and the dissolved oxygen concentration in the nitrification zone is 2mg / L.

[0059] The anaerobic ammonium oxidation zone, each short-range nitrification zone, and the nitrification zone are inoculated with activated sludge, and the slud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com