Synthesis method of ethyl 4-chloroacetoacetate

A technology of ethyl chloroacetoacetate and synthesis method, which is applied in the preparation of ketene/polyketene, organic chemistry, etc., can solve the problems of expanding production, high cost, and high activity of reactants, and achieve improved production efficiency and low equipment cost , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

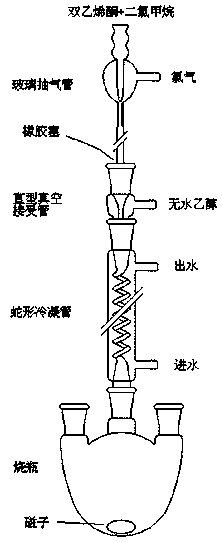

[0016] A kind of synthesis of ethyl 4-chloroacetoacetate, concrete implementation steps are as follows:

[0017] (1) 1100 g of diketene was diluted to 2500 mL with dichloromethane, and the mixed liquid was passed into the upper port of the glass suction pipe with a constant flow pump, and chlorine gas was passed from the liquid chlorine cylinder into the side port of the glass suction pipe; both diketene and chlorine gas used outer diameter 1 / 8-inch PTFE tube is used for transportation, and the connection between PTFE tube and glass exhaust pipe is wrapped and sealed with multi-layer raw material tape;

[0018] (2) Use a circulating water vacuum pump to make the internal pressure of the flask 0.03 MPa lower than the atmospheric pressure, adjust the constant flow pump to feed the mixture of diketene and dichloromethane at a rate of 15 mL / min, and use a tetrafluoroneedle valve to adjust the chlorine gas rate to 5.56 g / min (the molar ratio of diketene and chlorine is 1:1), and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com