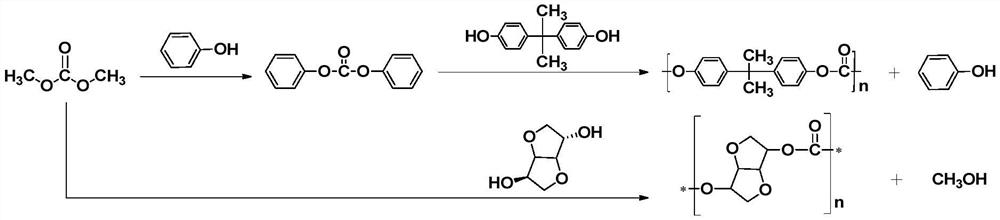

A compound catalyst and its application in the preparation of bio-based polycarbonate

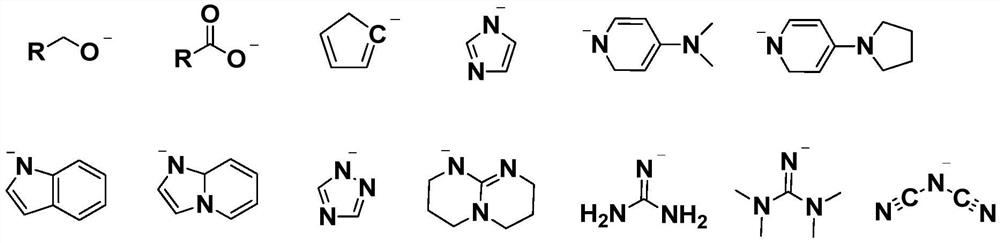

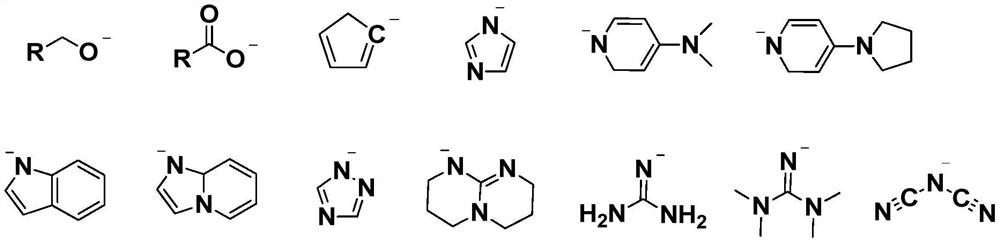

A composite catalyst based polycarbonate technology, which is applied in clean catalysis and green fields, can solve the problems of insufficient reaction of trace isosorbide, poor catalyst stability, low reaction catalytic activity, etc., and achieve shortened reaction time and high product yield Improve, enhance the effect of activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The synthetic method of polycarbonate, step is as follows:

[0052]

Embodiment 2

[0063] The difference from Comparative Example 1 is that the catalyst used is changed to the main catalyst sodium iodide 30 × 10 -3 g (2×10 of the amount of isosorbide substance -1 %) cocatalyst sodium imidazole 18 × 10 -3 g (2×10 of the amount of isosorbide substance -1 %), other conditions are constant, the yield of gained polycarbonate is 95%, and number average molecular weight is 2.5 * 10 4 .

Embodiment 3

[0065] The synthetic method of polycarbonate, step is as follows:

[0066] The only difference with Example 1 is that the raw materials used are 14.6g (0.10mol) isosorbide and 270g (3mol) dimethyl carbonate, and the promotor is sodium phenoxide 23.5 × 10 -3 g (2×10 of the amount of isosorbide substance -1 %), other conditions are constant, the yield of gained polycarbonate is 99%, and number average molecular weight is 3 * 10 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com