Motor full-life-cycle management and control system

A technology of full life cycle and control system, which is applied in the field of motor full life cycle control system, can solve the problems of lack of full life cycle management of motors, lack of real-time analysis of motor status, and few monitoring methods, so as to achieve perfect equipment information management, increase Effective working hours and reduced downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

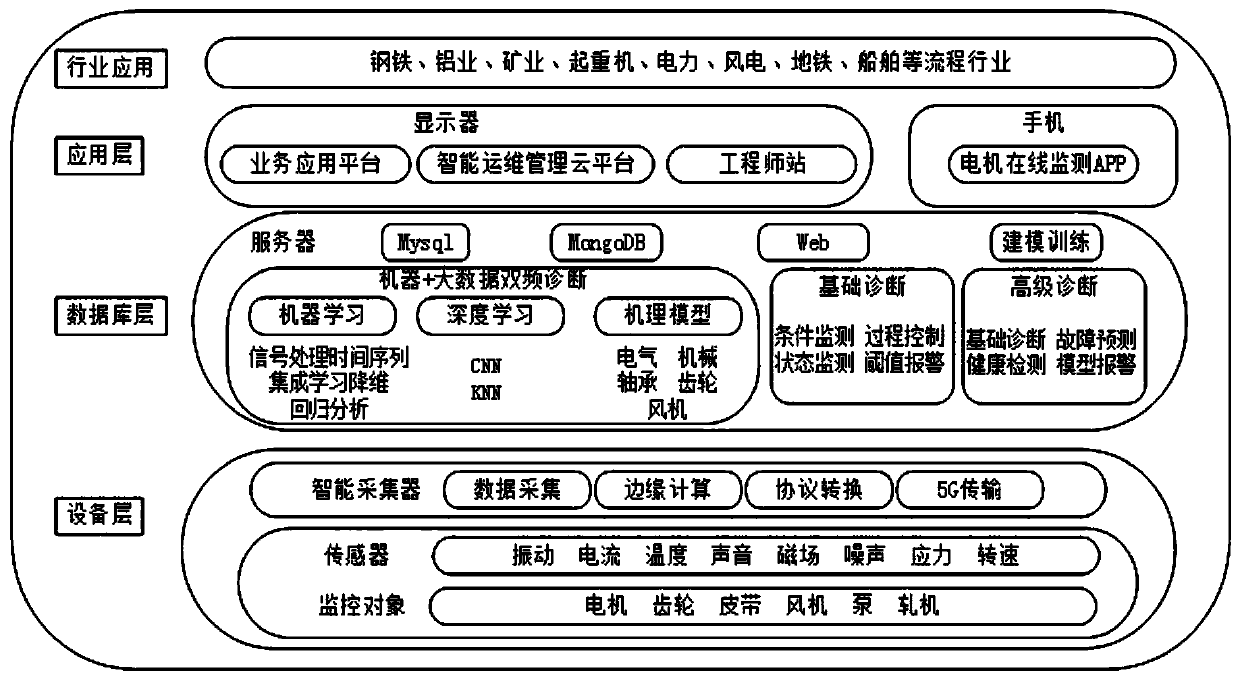

[0035] like figure 1 As shown, a motor life cycle management and control system includes data collectors, servers, LCD screens and equipment life cycle management and control systems. The equipment life cycle management and control system includes business application platforms, engineer stations, intelligent operation and maintenance management cloud platforms and Motor online monitoring APP; the server of the system of the present invention is deployed in the monitoring room, and the collected data is transmitted to the server through the local area network or 5G. The business application platform, engineer station, and intelligent operation and maintenance platform can be displayed and operated through the display screen, and the motor online monitoring APP It can be displayed on the mobile terminal.

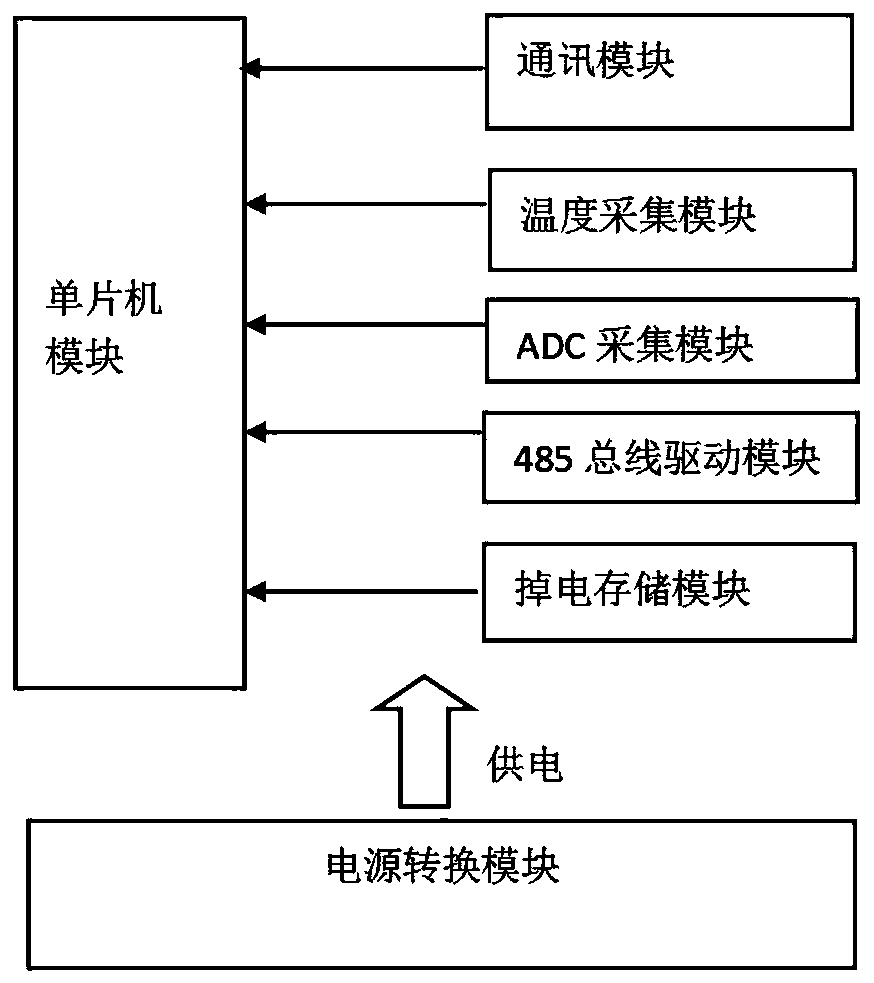

[0036] like figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com