Patents

Literature

38 results about "Motor point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods to place one or more leads in muscle for providing electrical stimulation to treat pain

InactiveUS20100036454A1Relief the painPain reliefInternal electrodesExternal electrodesElectricityPhysical therapy

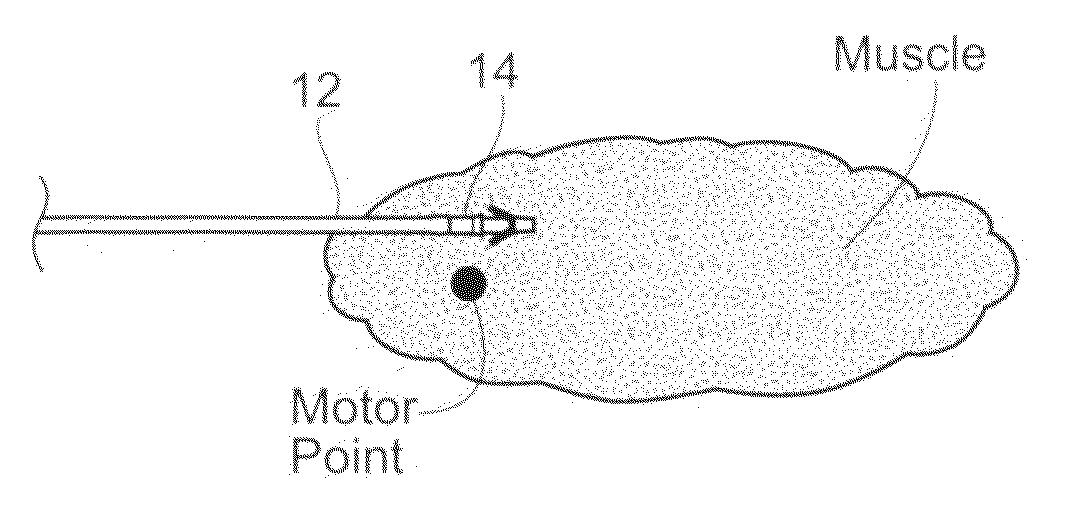

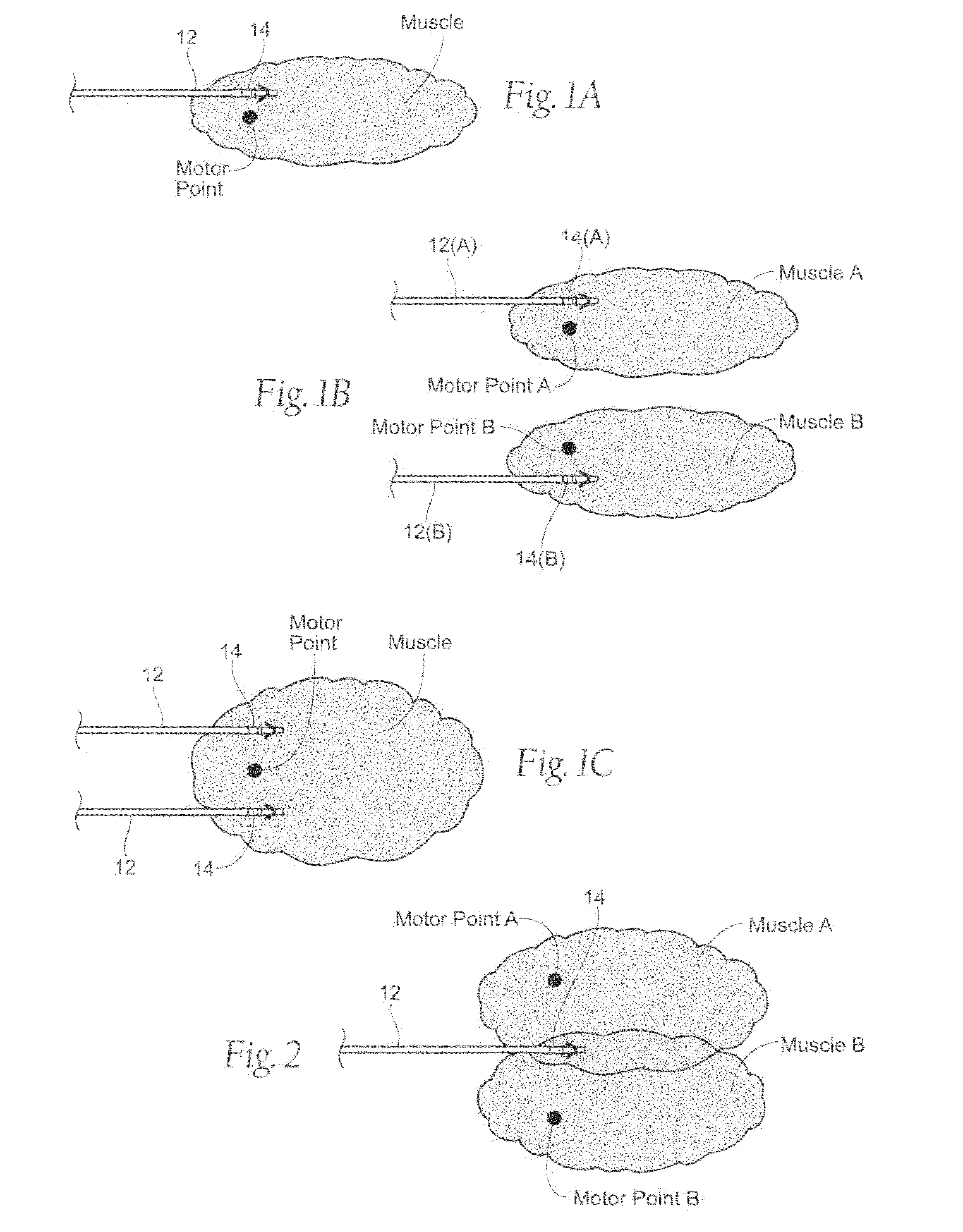

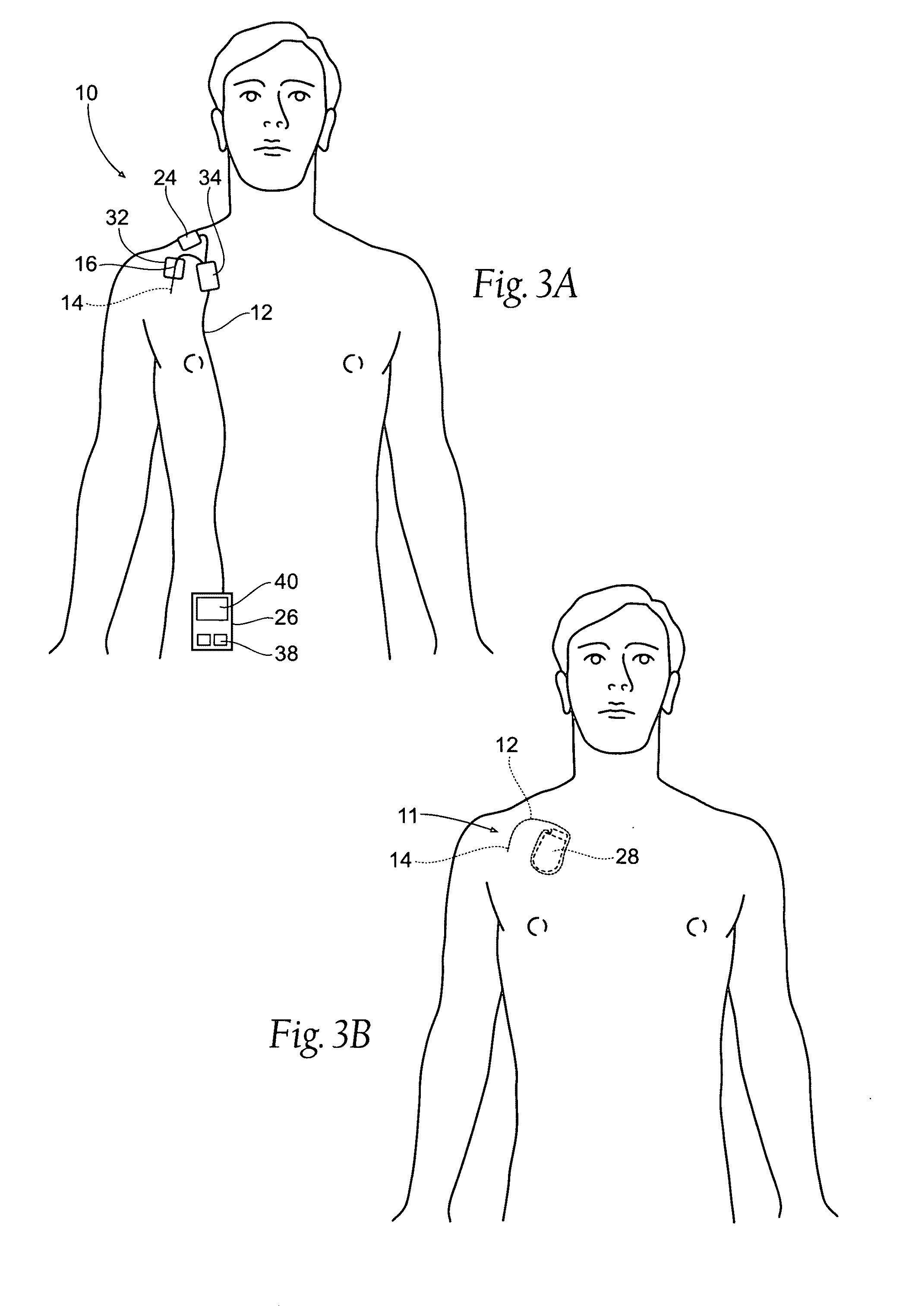

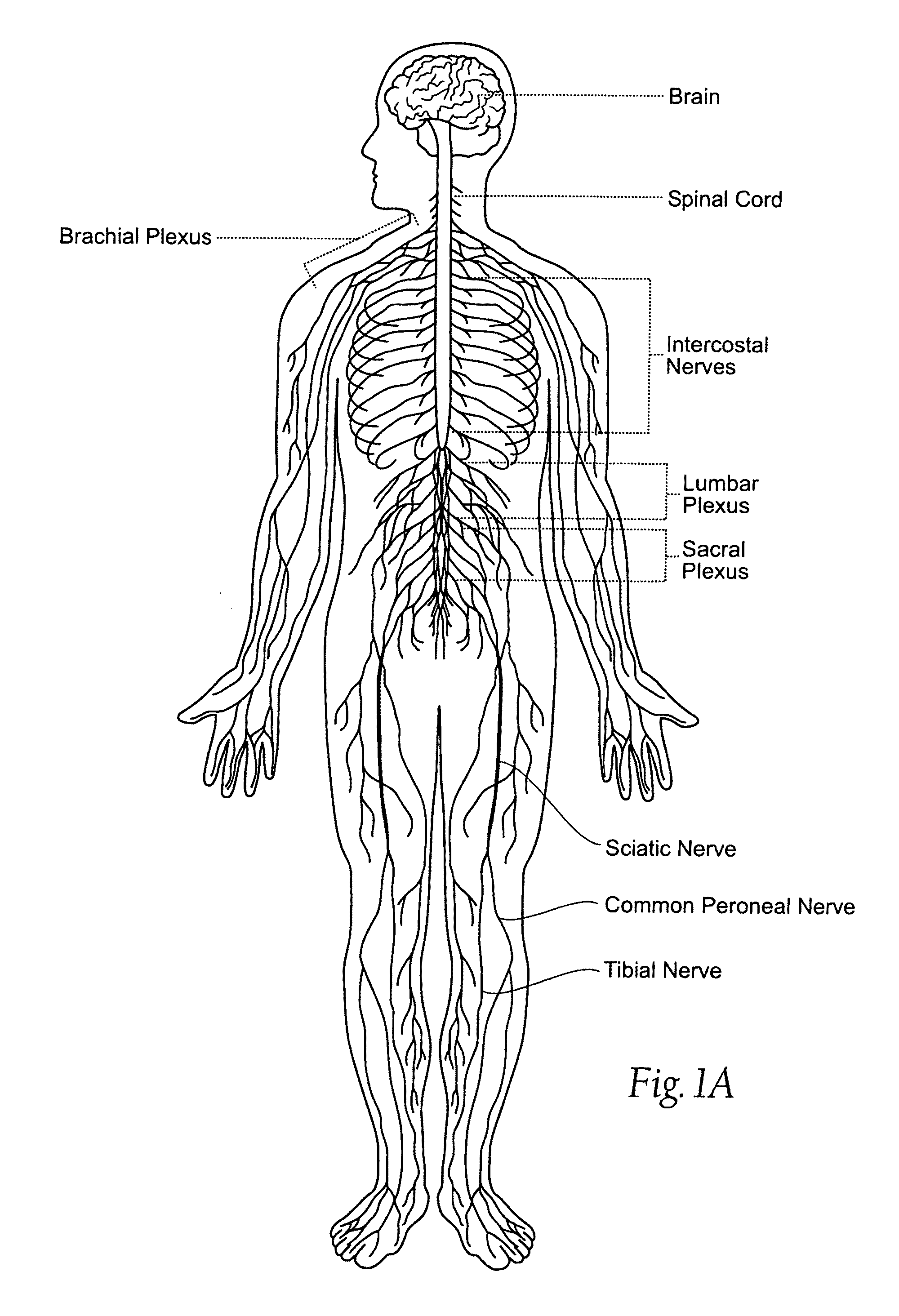

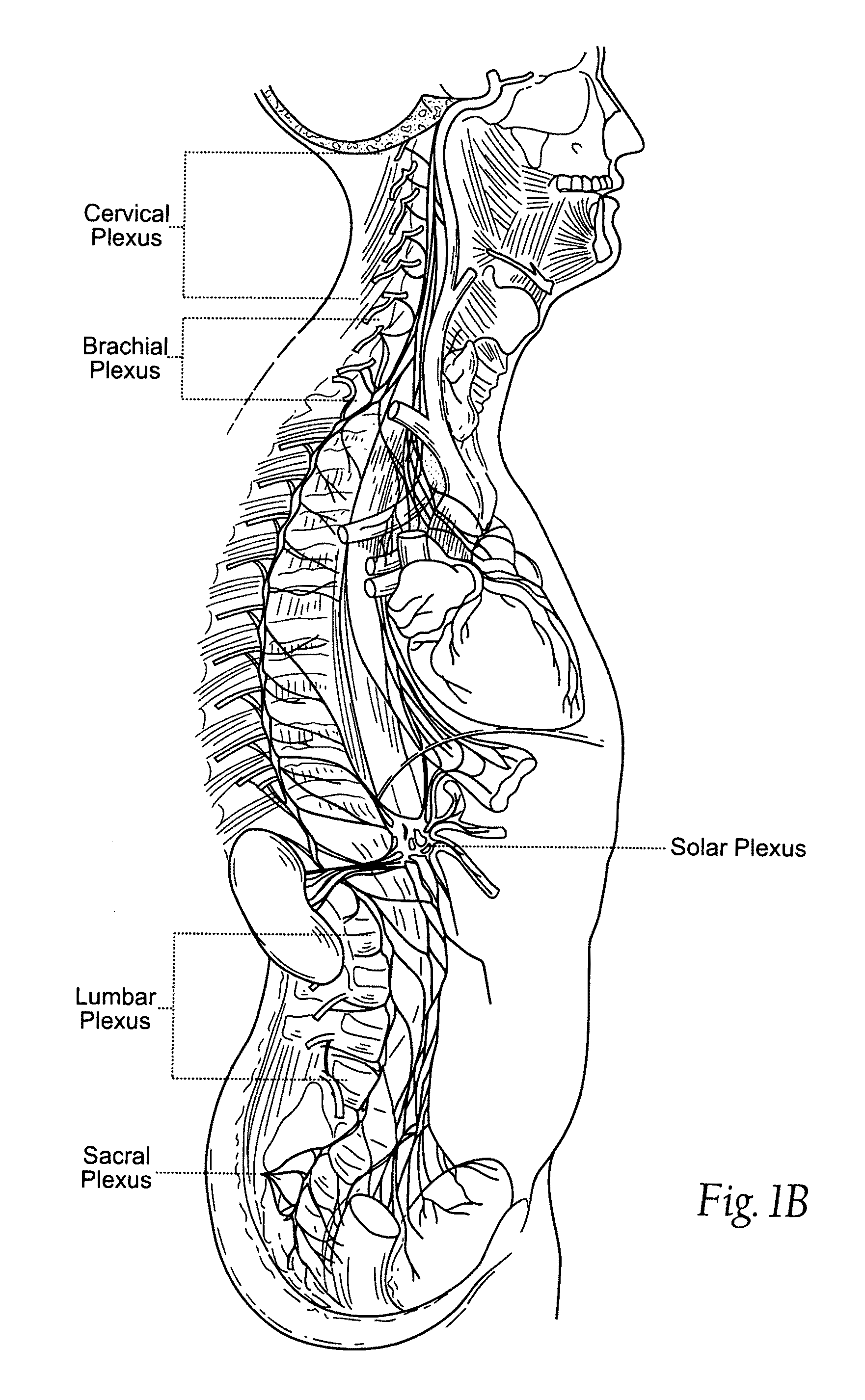

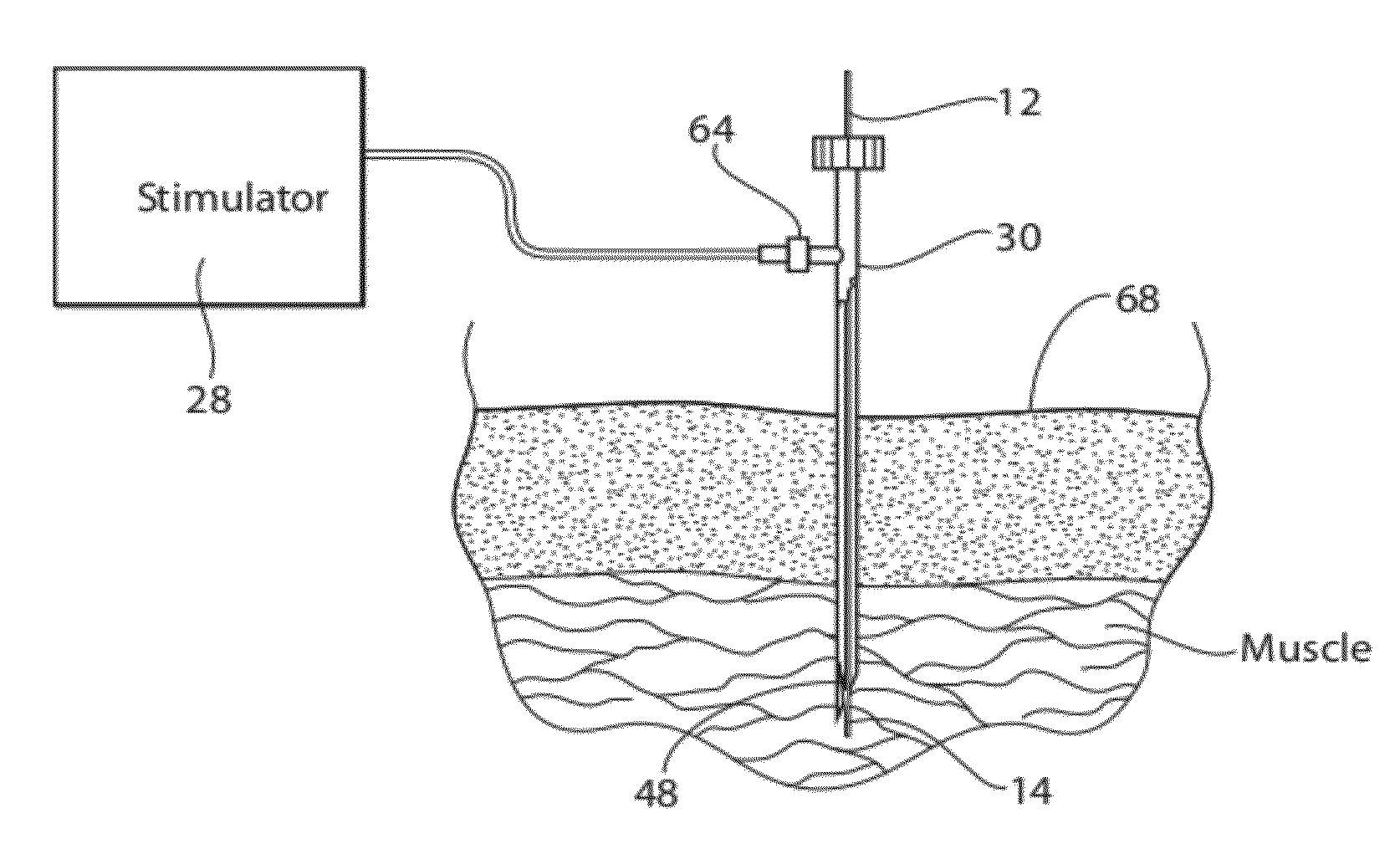

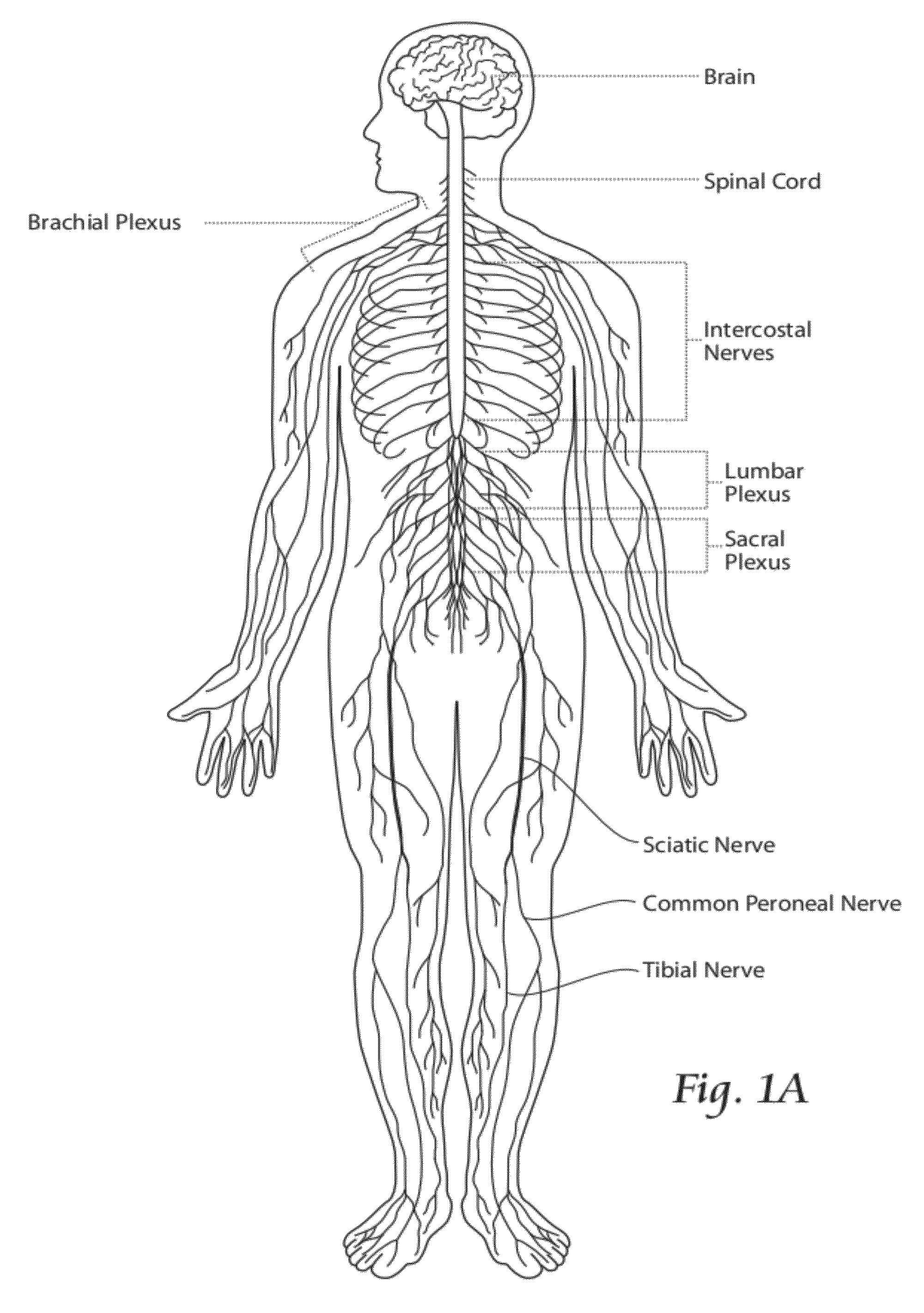

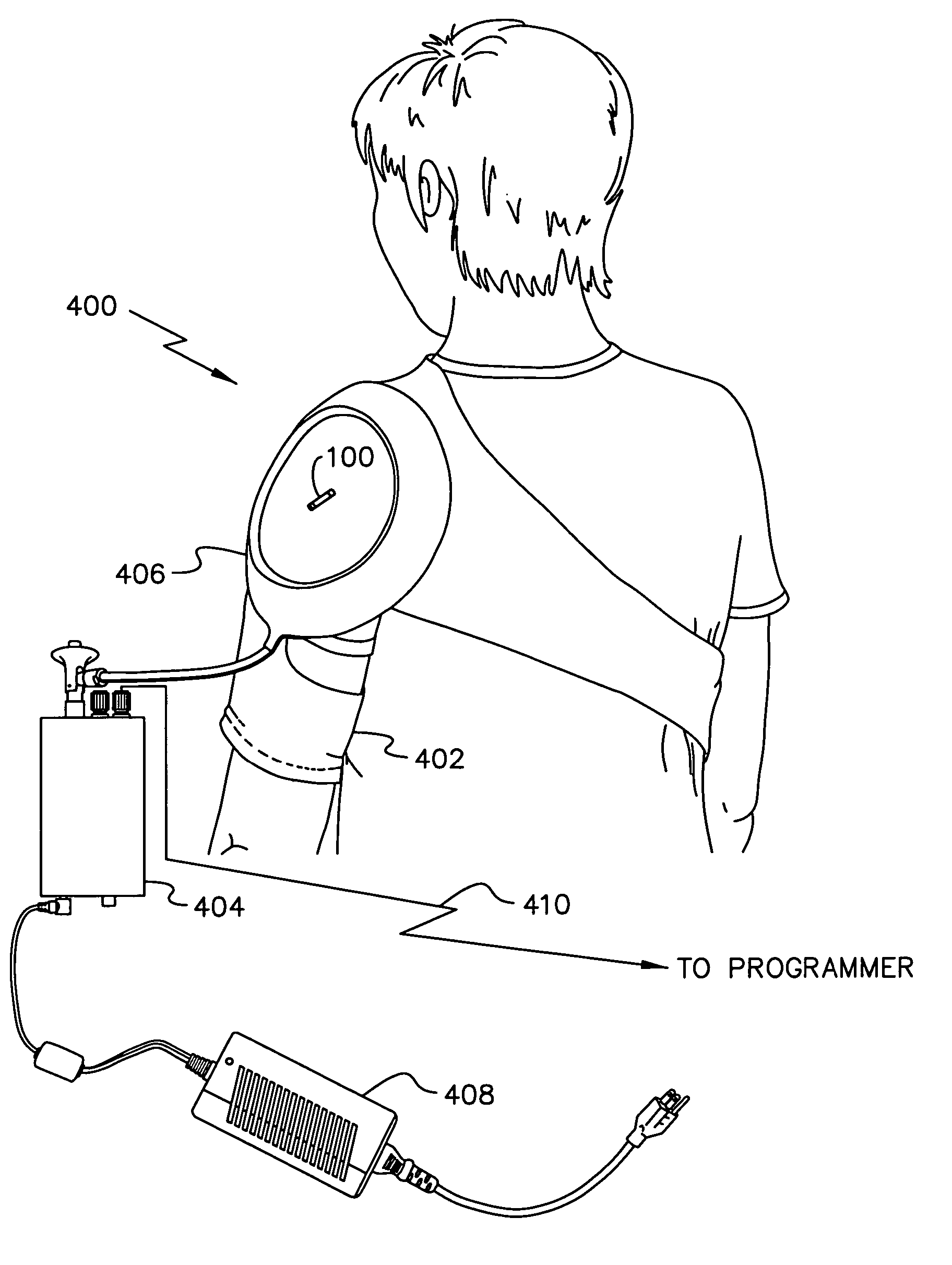

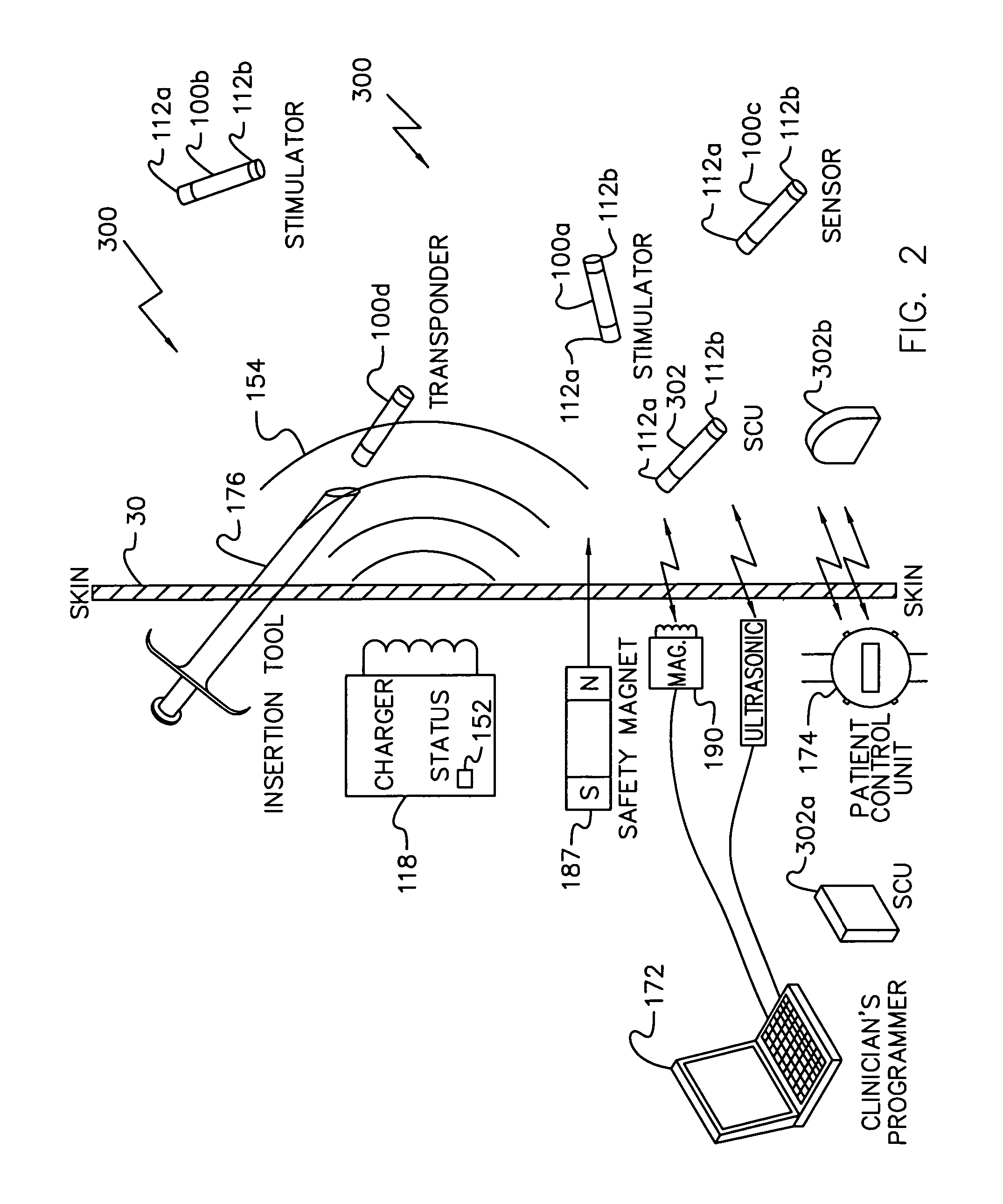

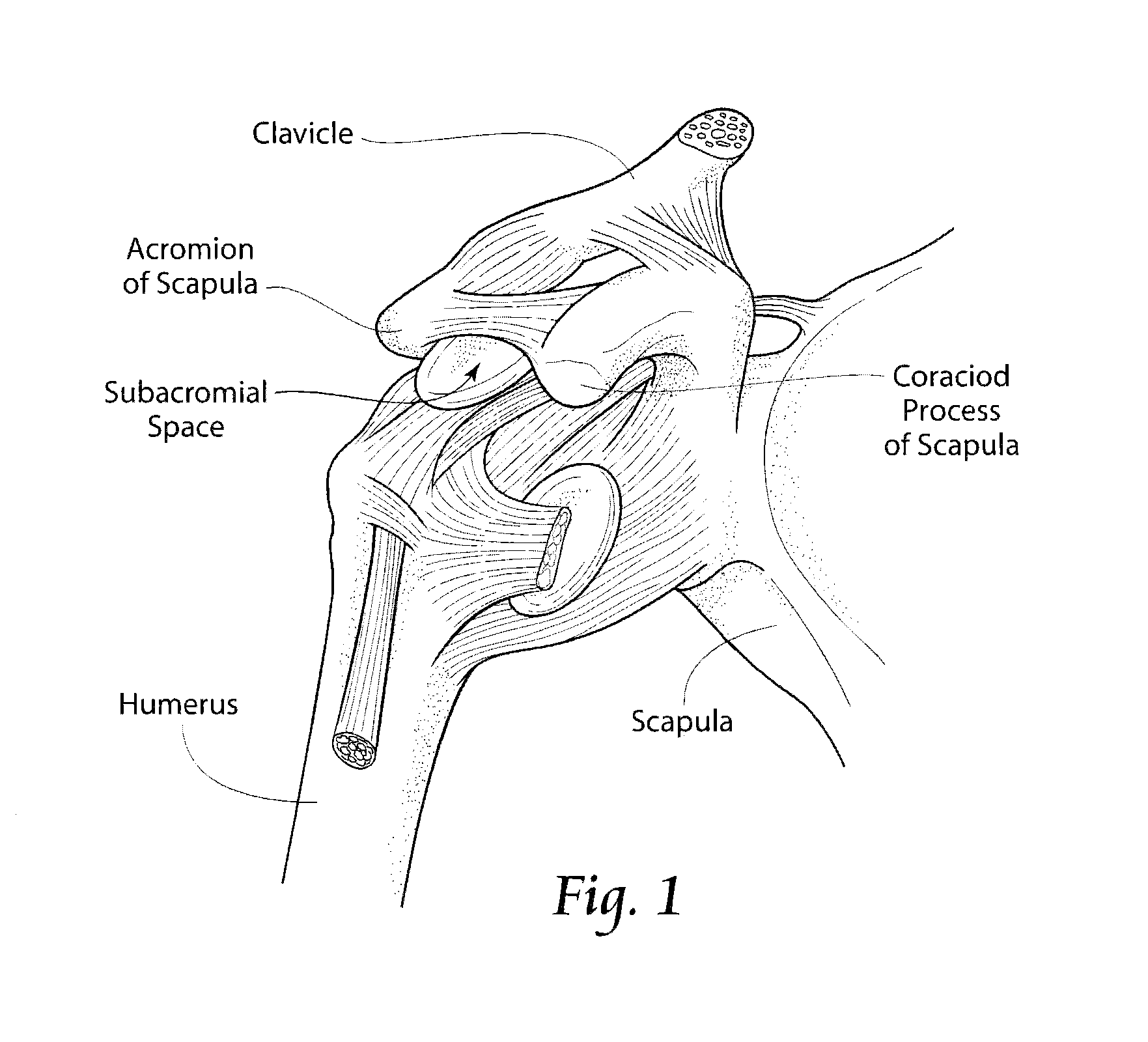

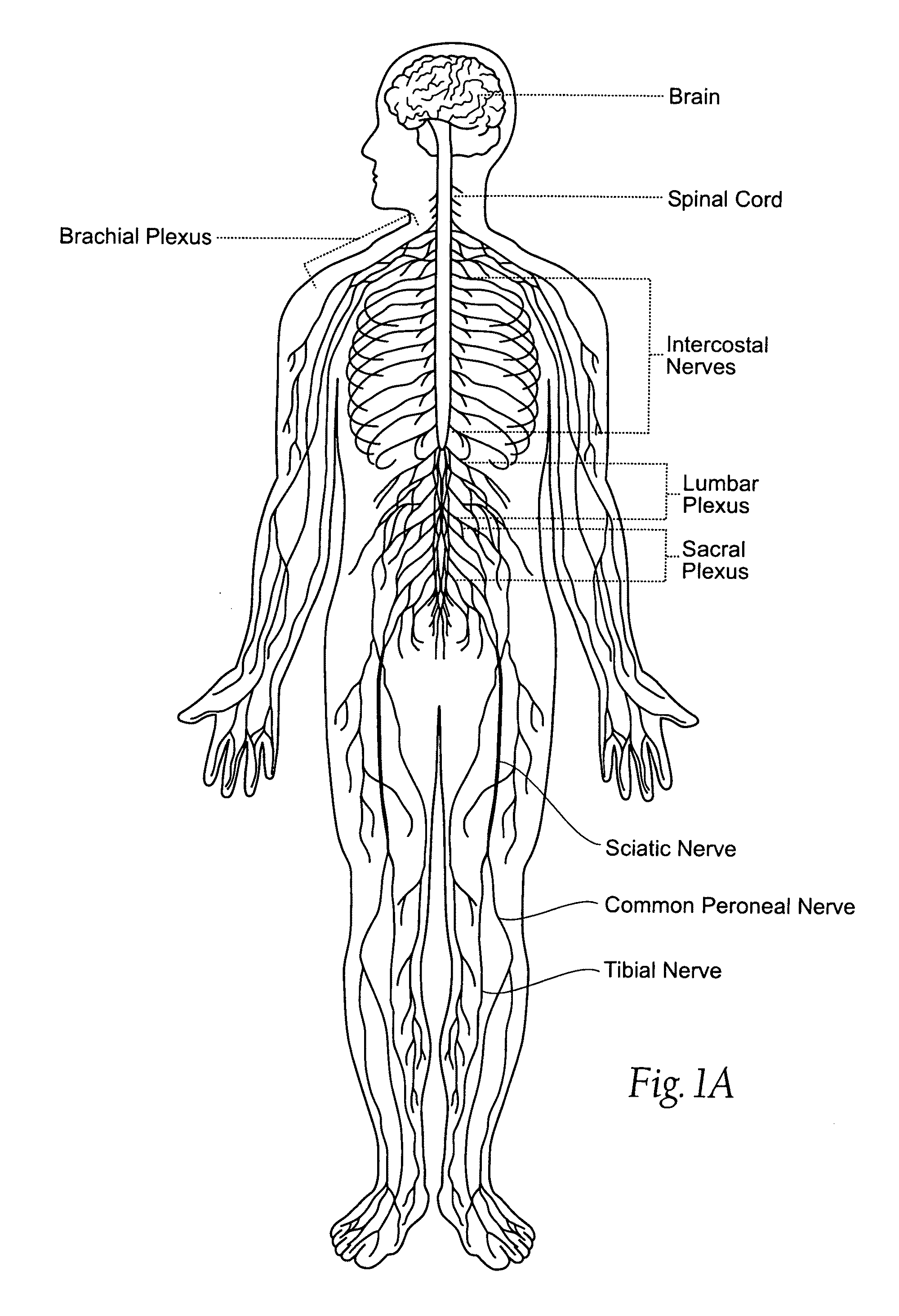

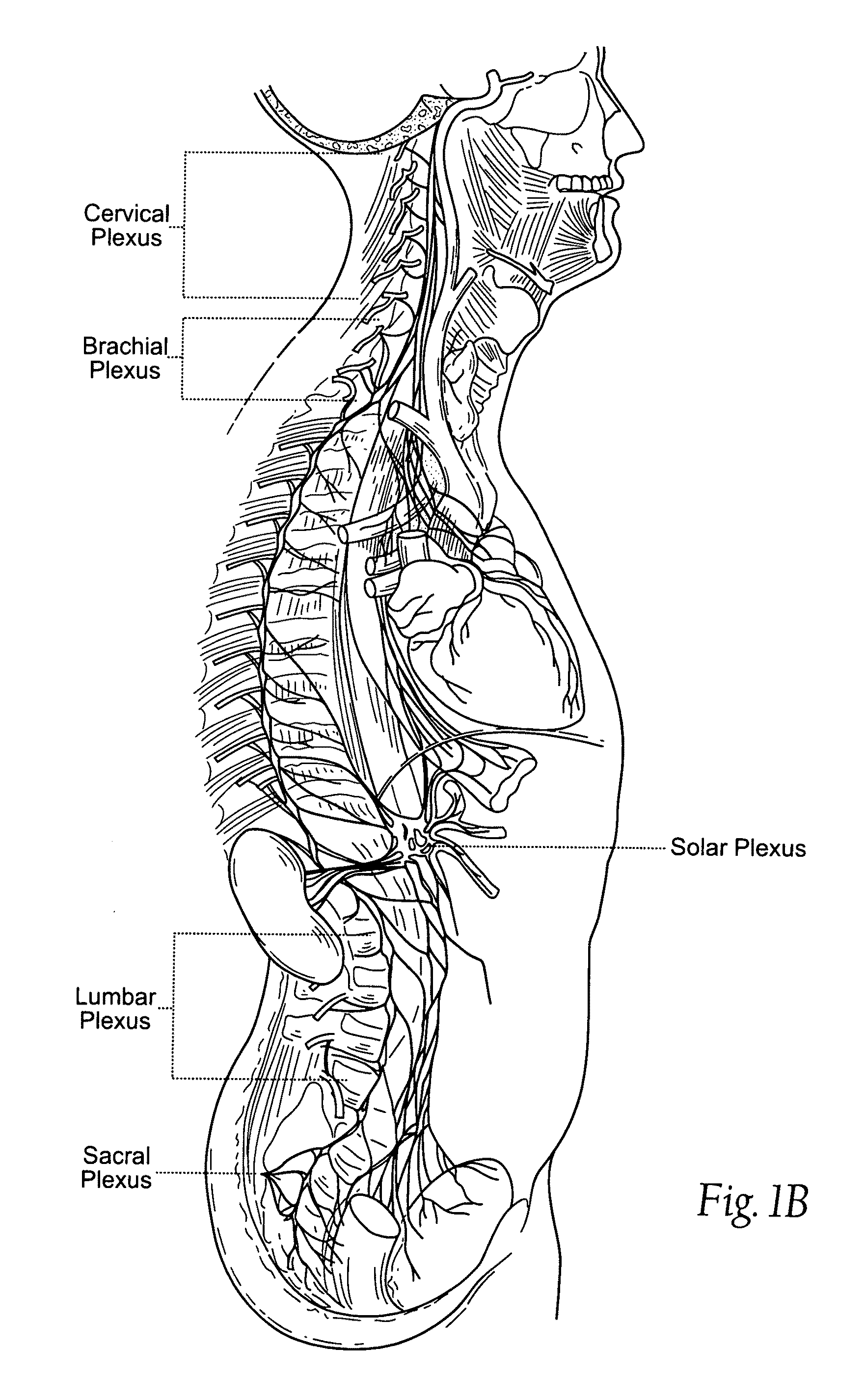

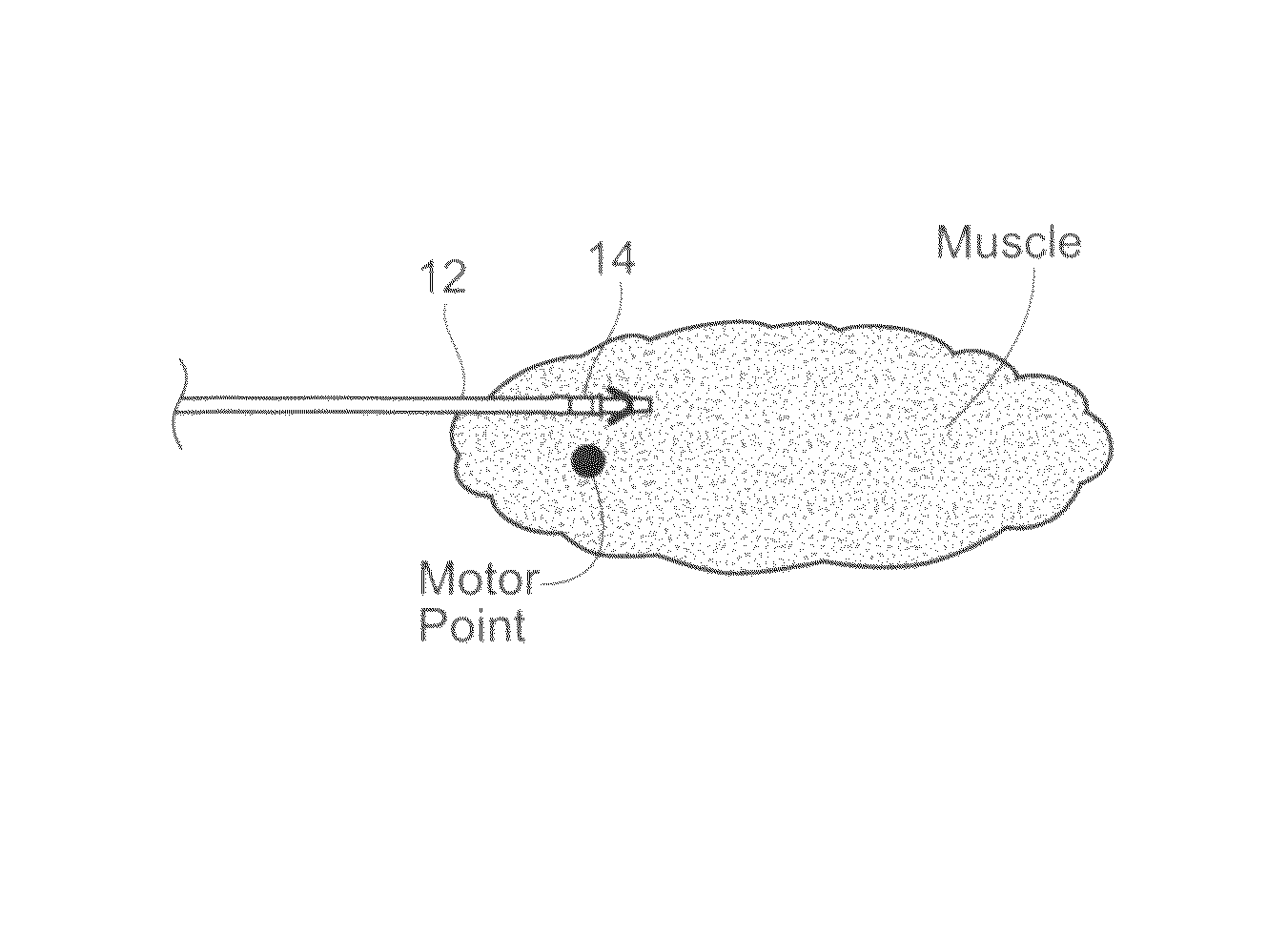

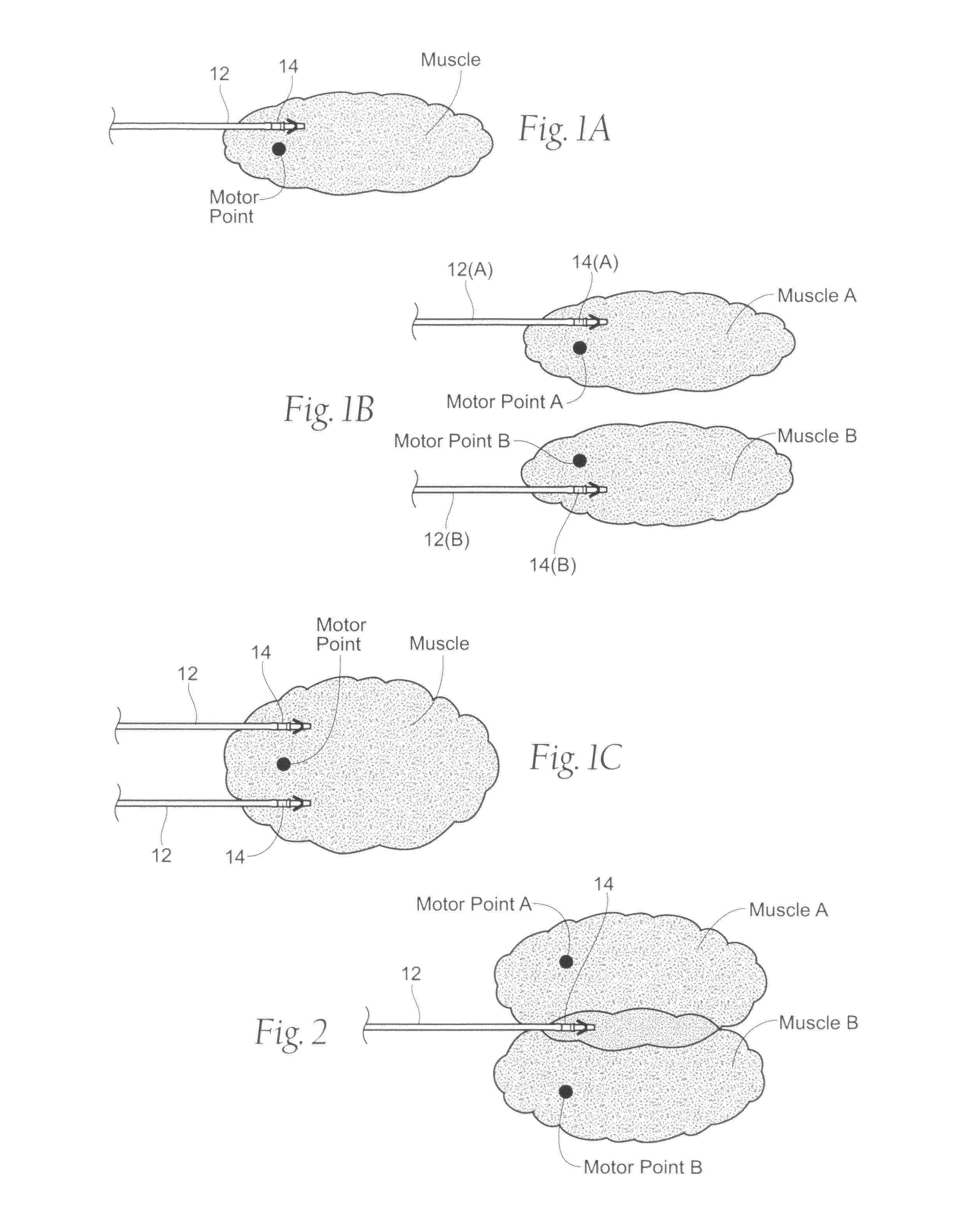

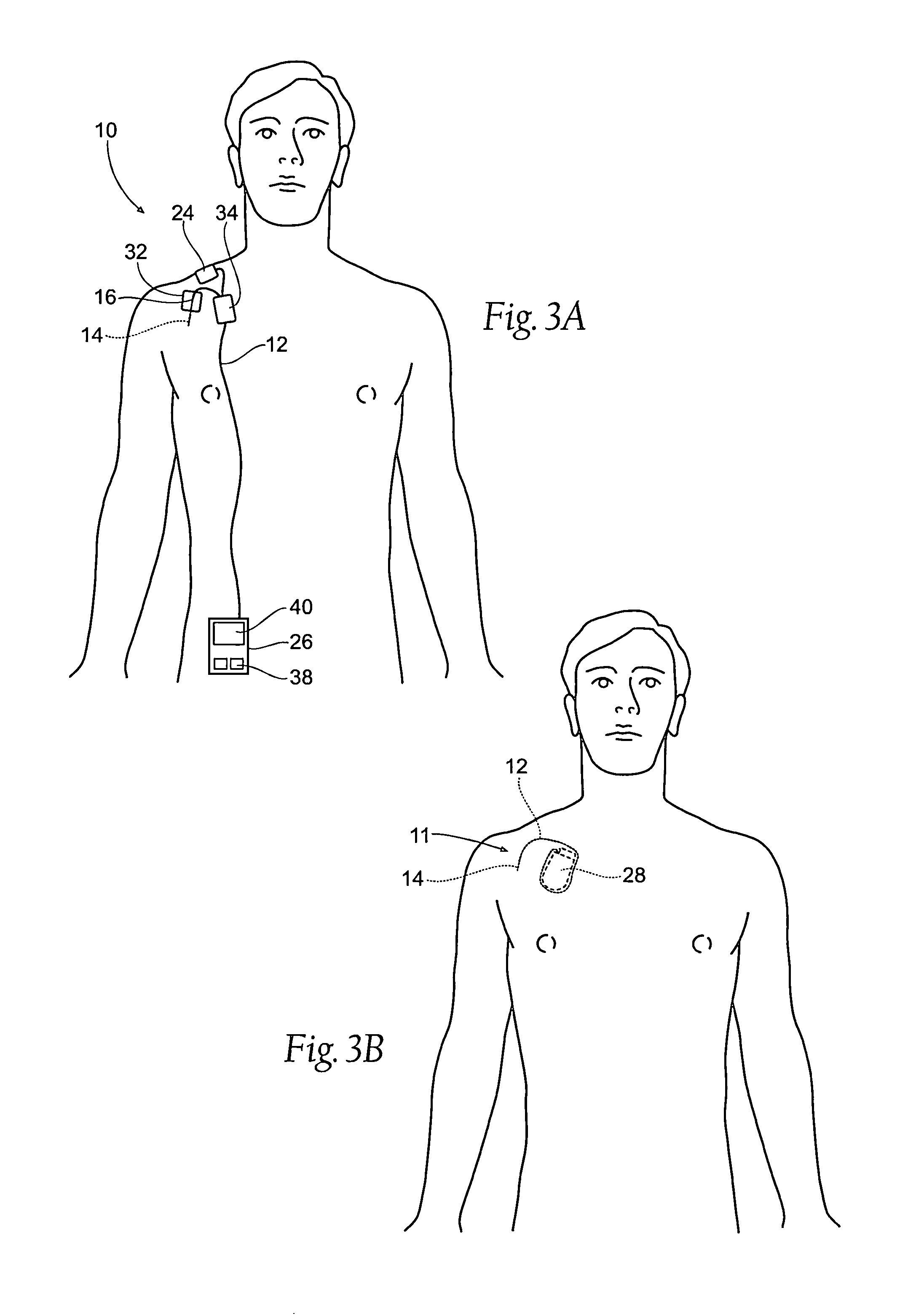

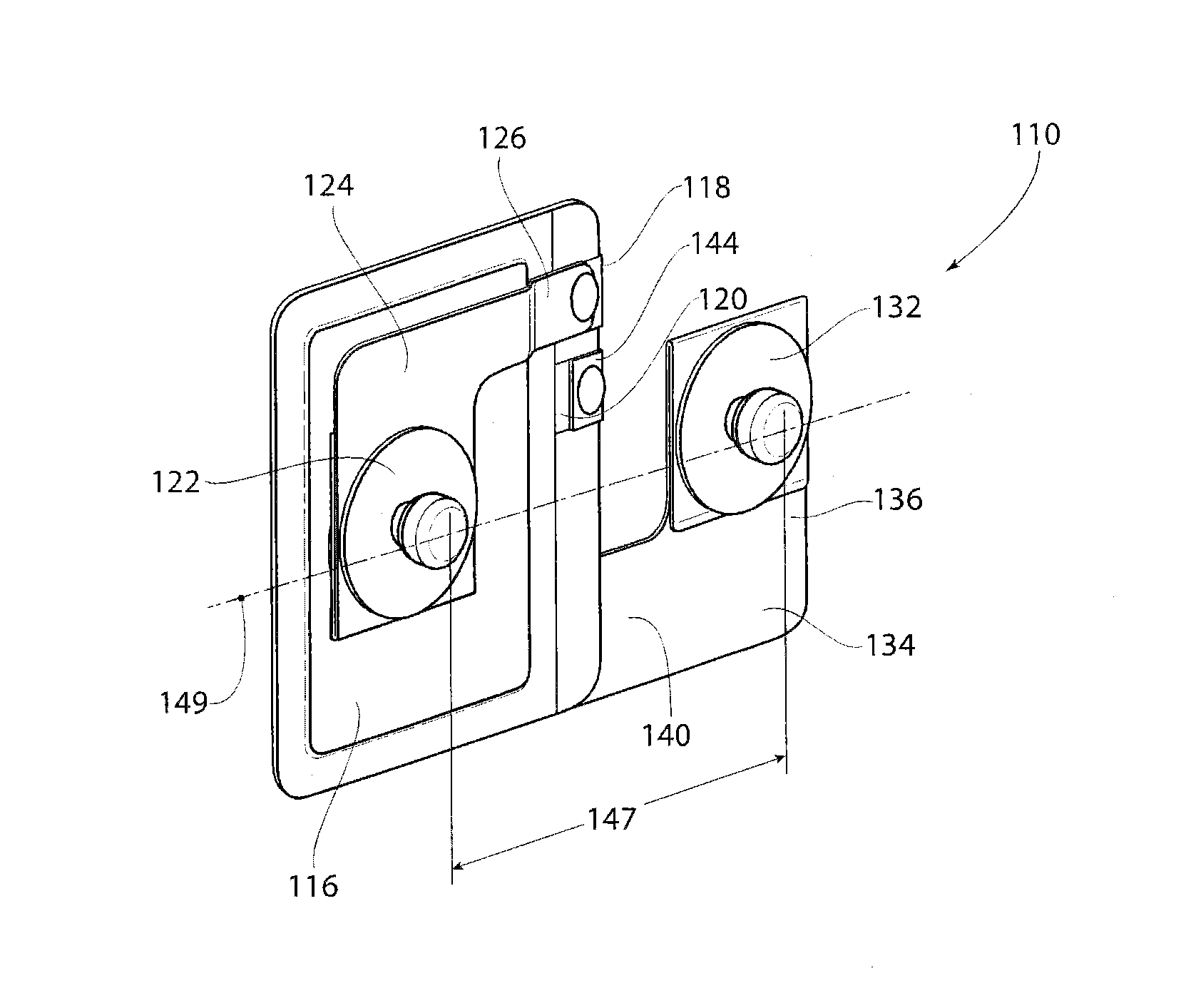

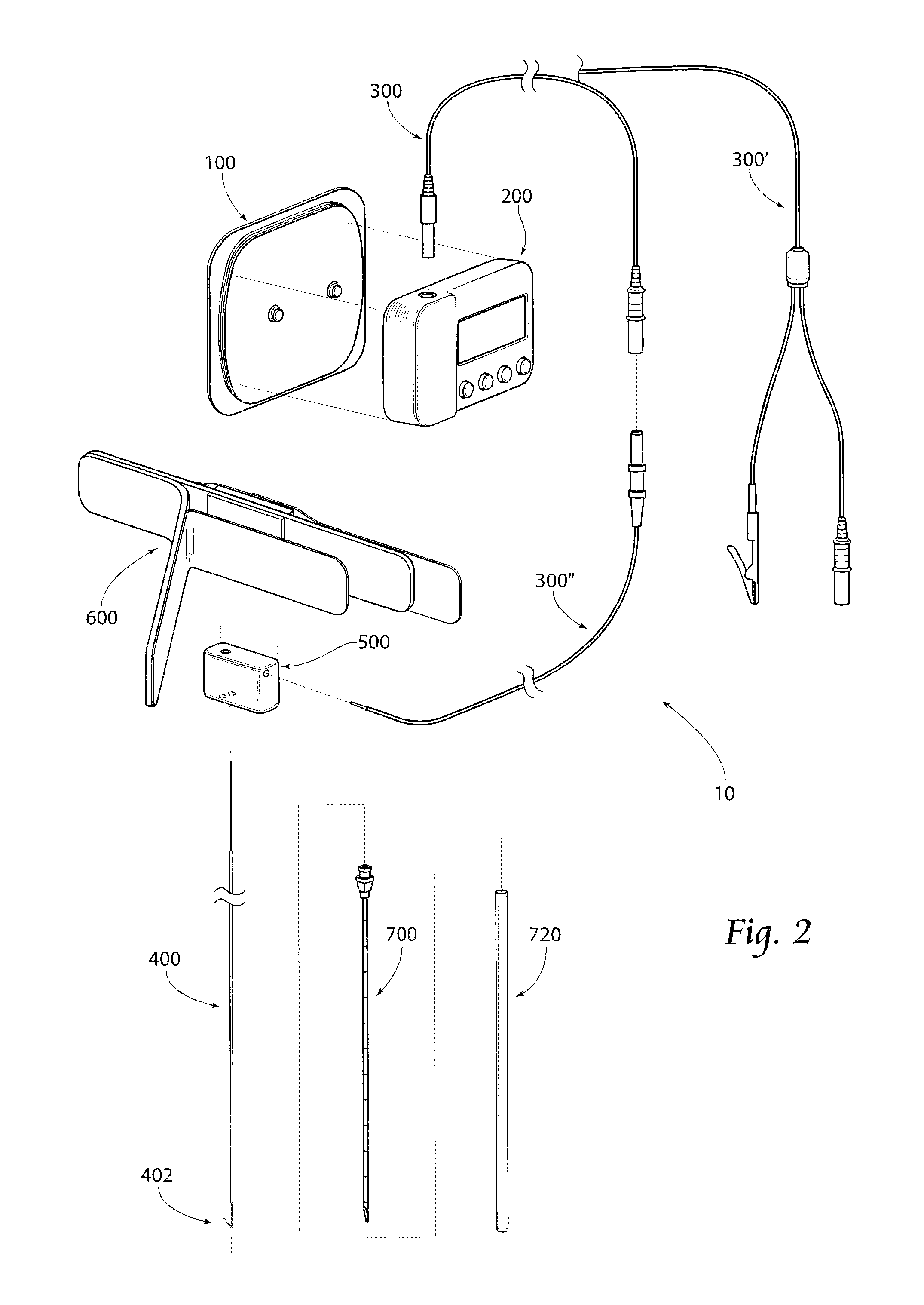

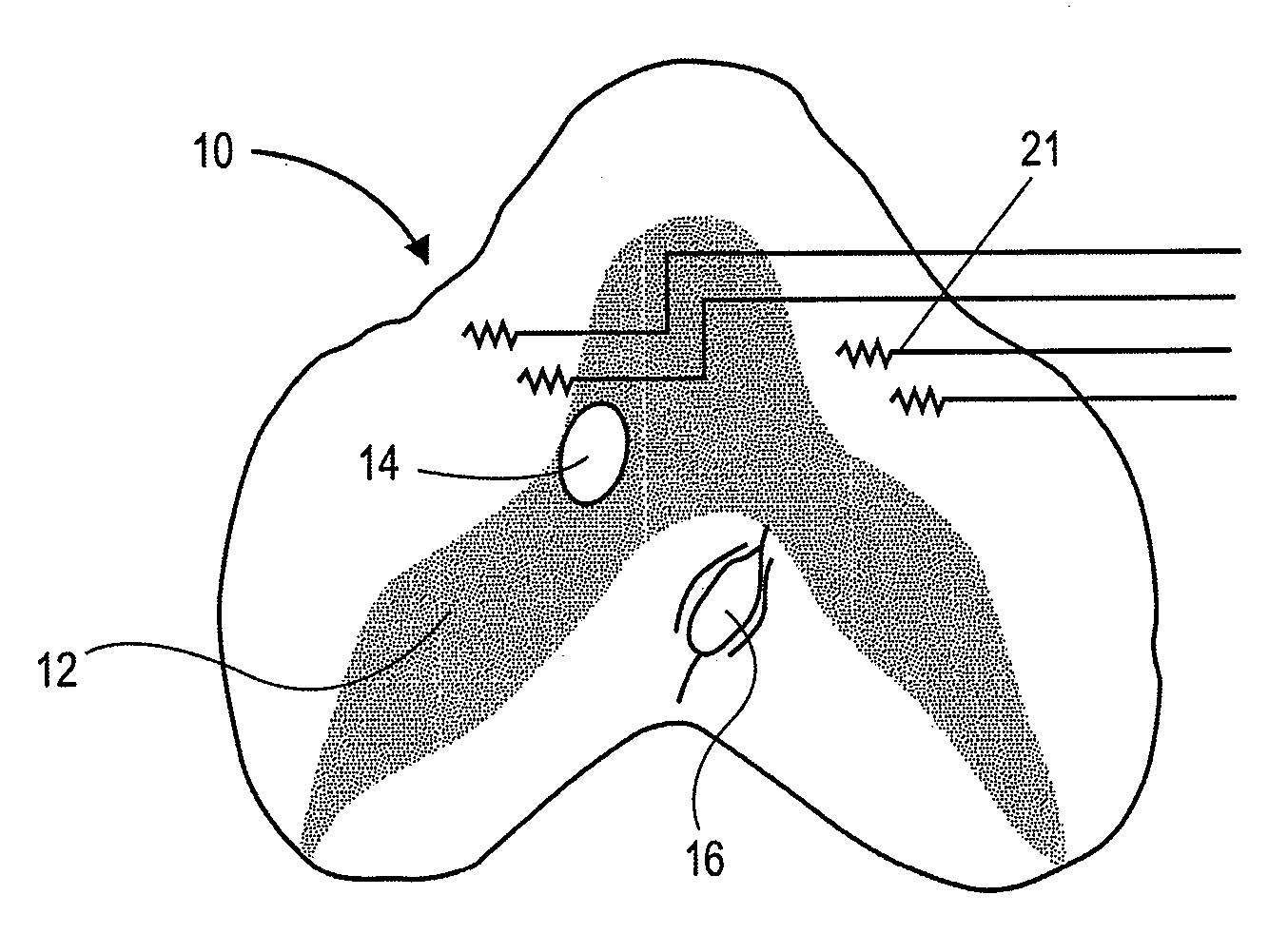

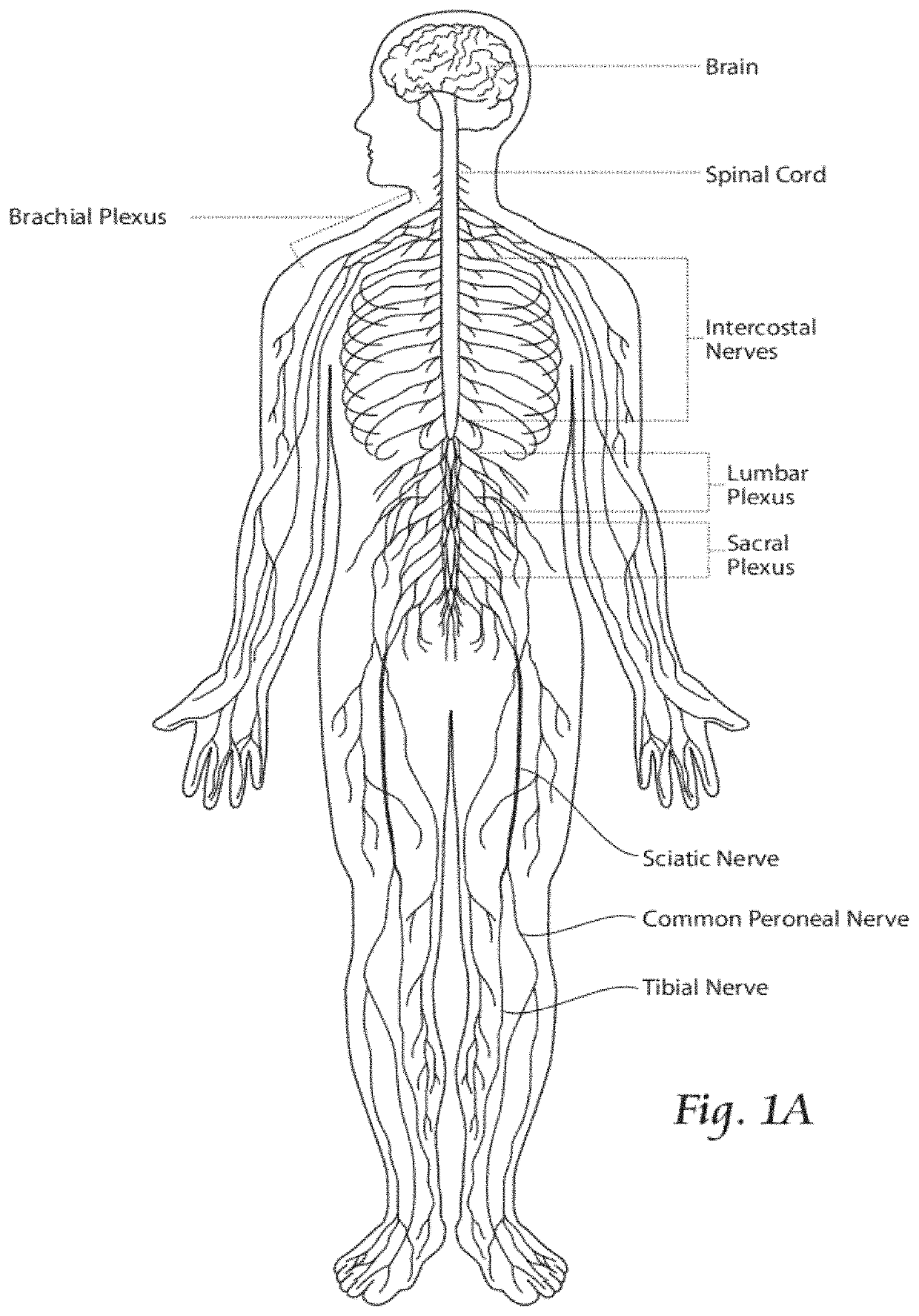

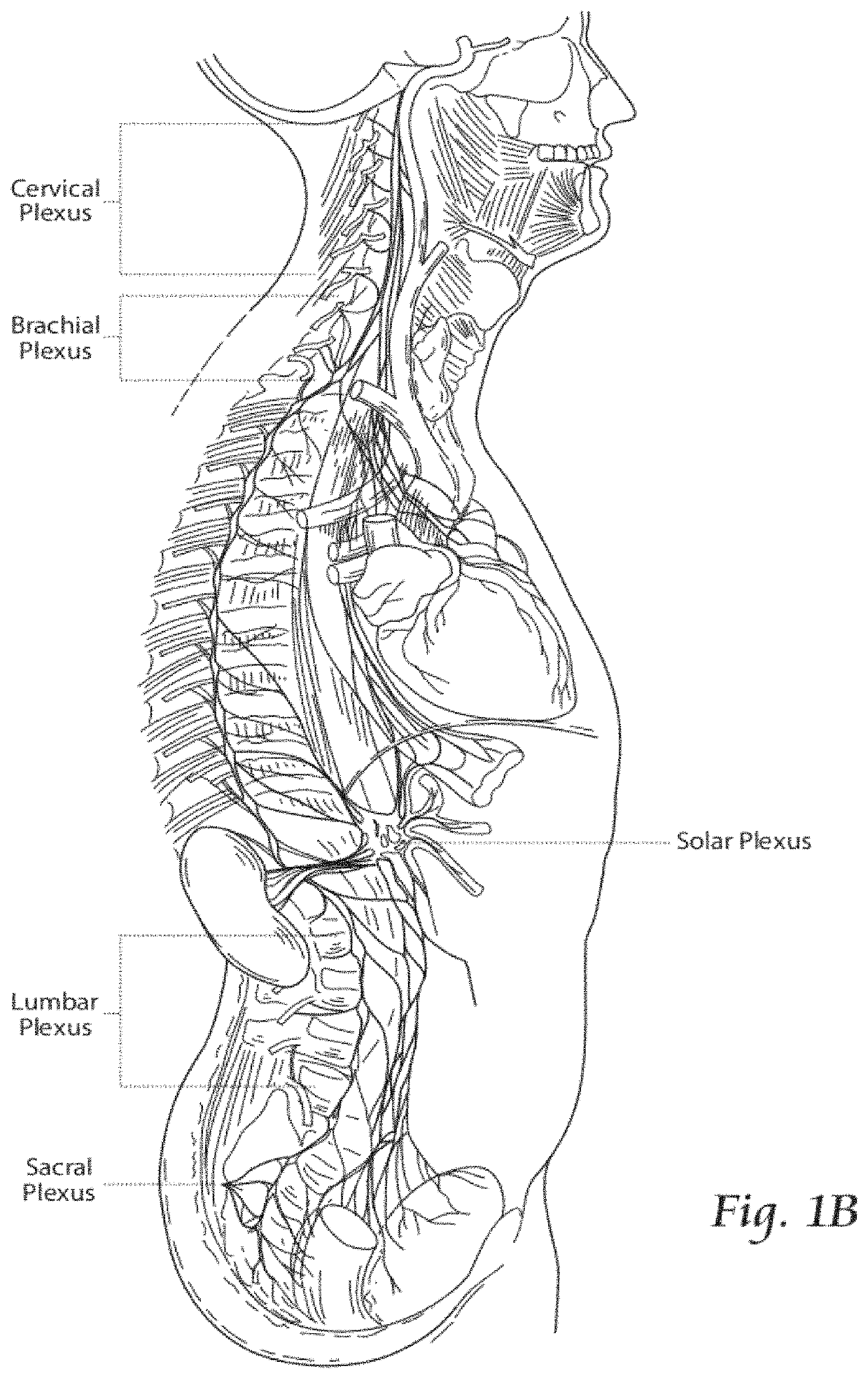

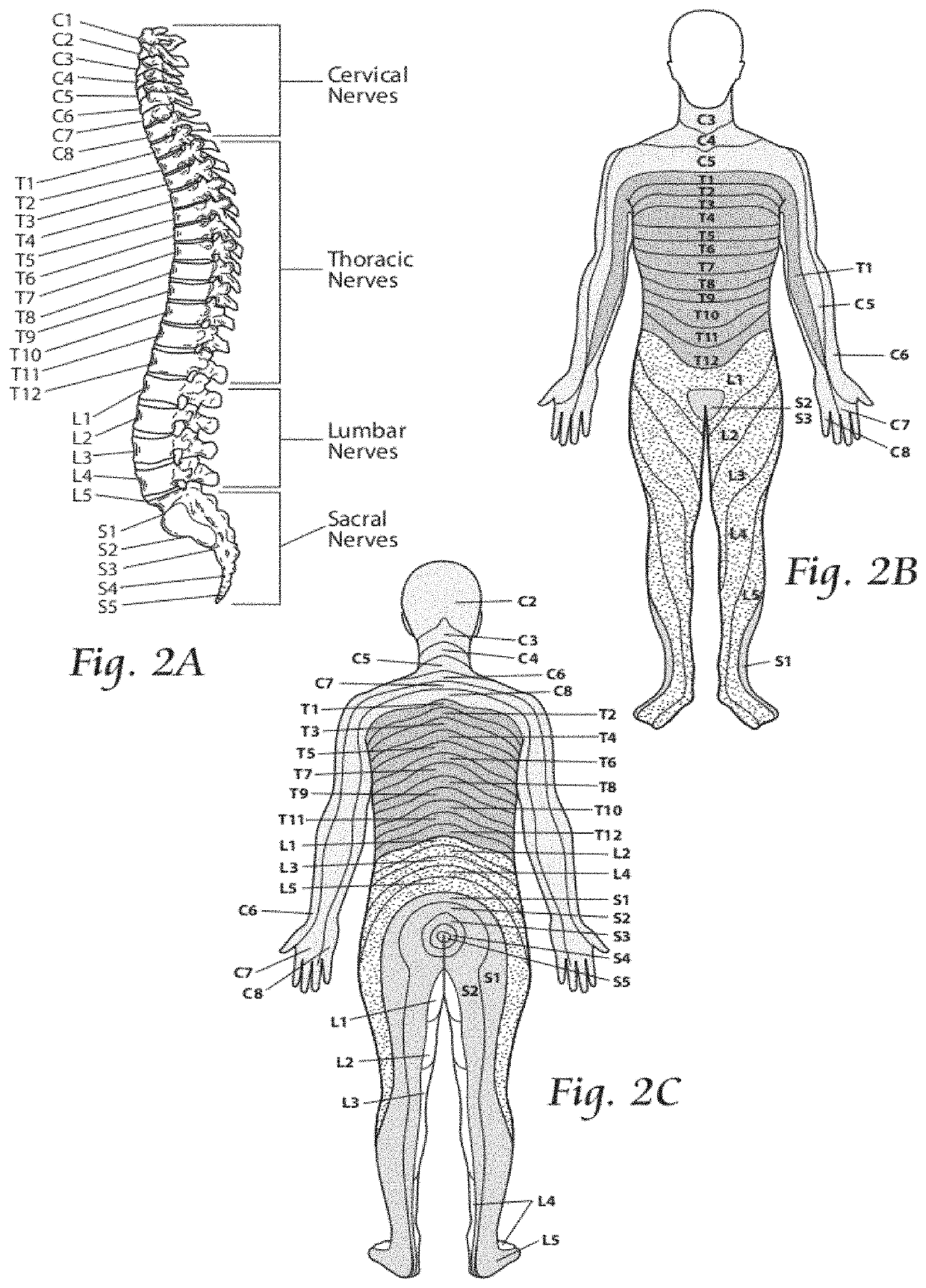

Systems and methods are adapted to provide the relief of pain. The systems and methods make possible the percutaneous placement of one or more intramuscular leads, without the need for fluoroscopy, for providing electrical stimulation to activate a motor point innervating the muscle, to provide the therapeutic relief of pain. The one or more intramuscular leads may be placed in muscle(s) to resist migration. The target nerves and their motor points innervate the muscles in which the one or more leads are placed. The systems and methods can include a two-stage solution. The first stage may include temporary systems and methods, including the use of an external pulse generator. The second stage may include more permanent systems and methods, including the use of an implanted pulse generator.

Owner:SPR THERAPEUTICS

Systems and methods to place one or more leads in tissue to electrically stimulate nerves of passage to treat pain

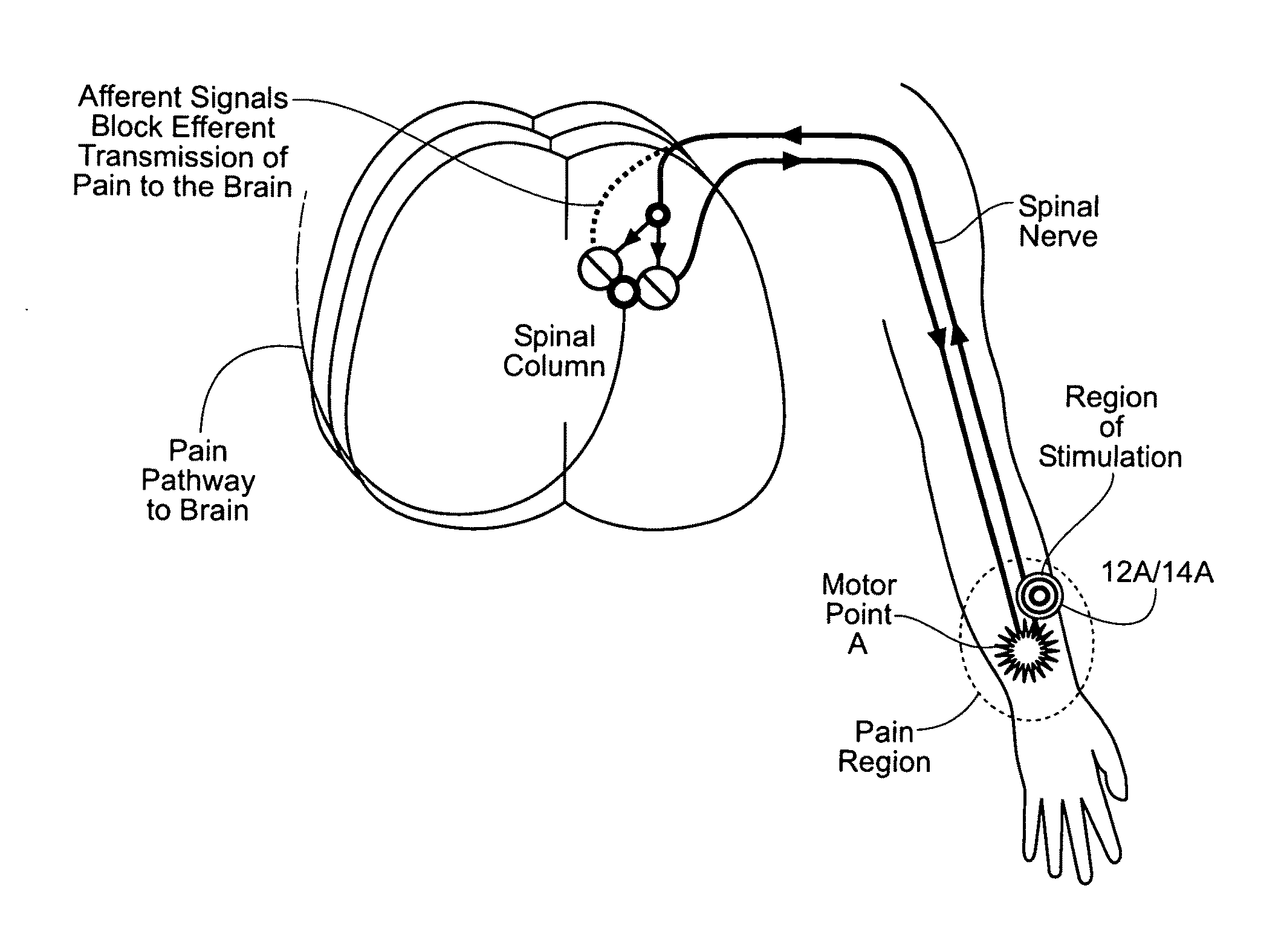

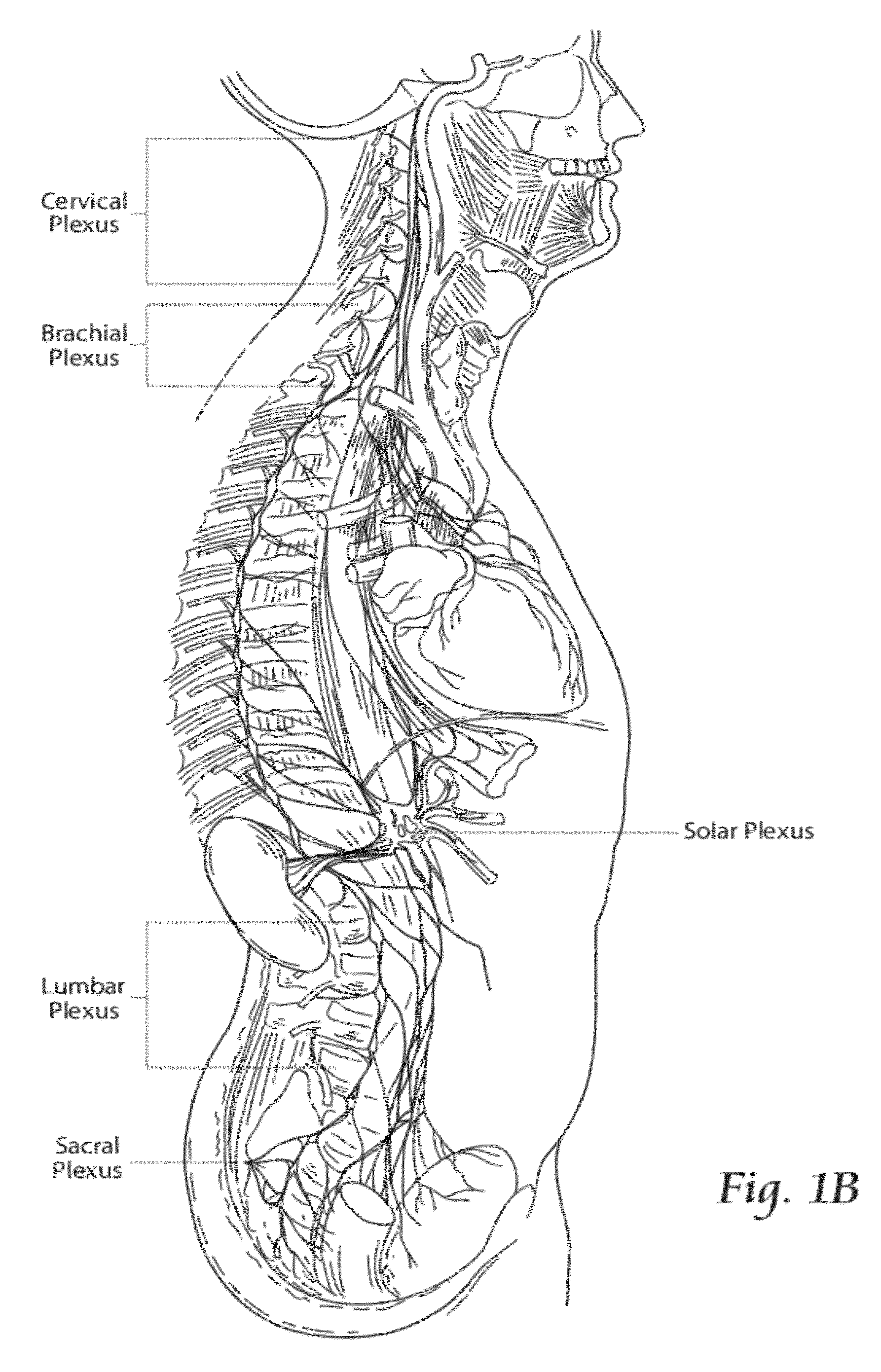

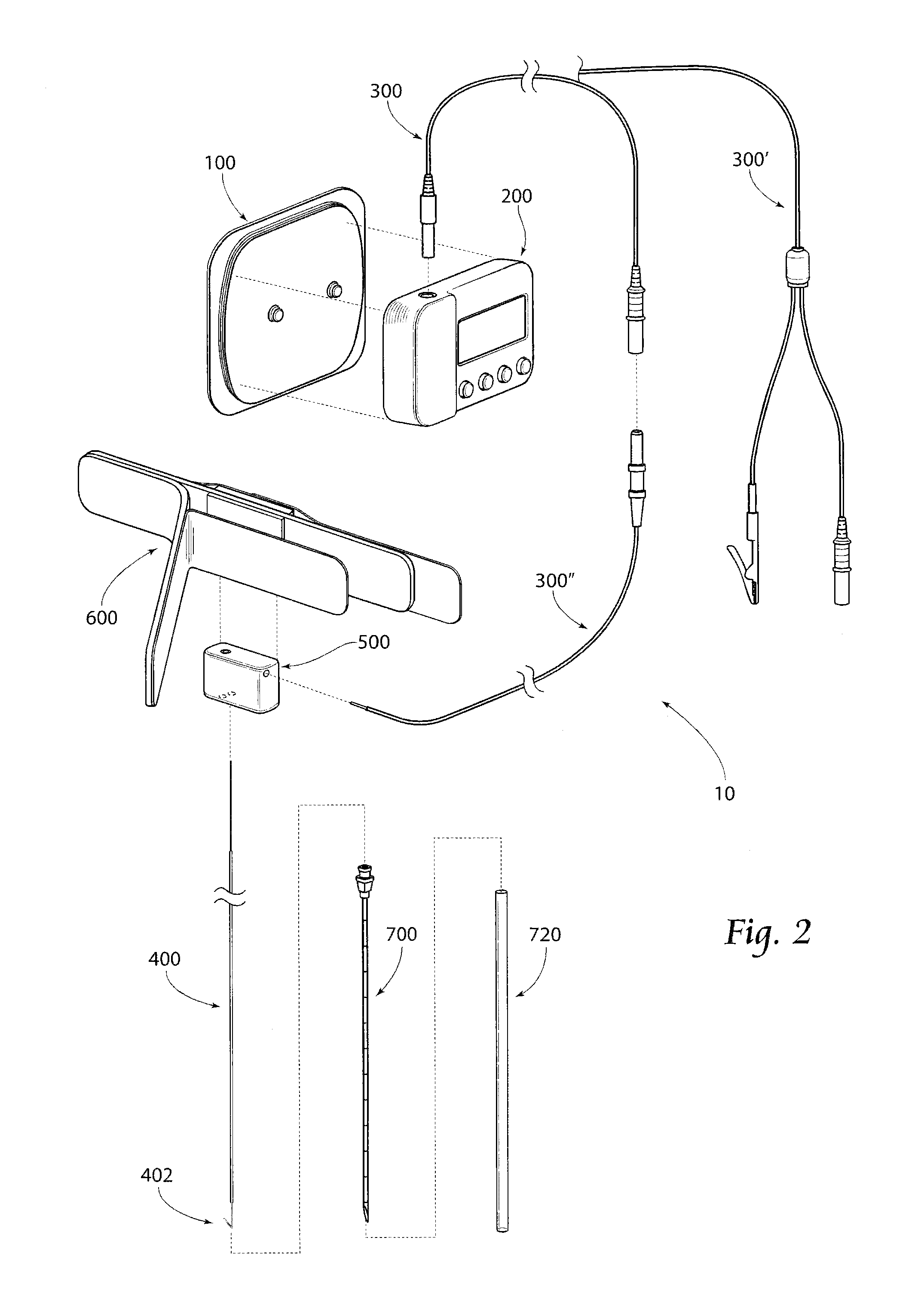

It has been discovered that pain felt in a given region of the body can be treated, not by motor point stimulation of muscle in the local region where pain is felt, but by stimulating muscle close to a “nerve of passage” in a region that is superior (i.e., cranial or upstream toward the spinal column) to the region where pain is felt. Spinal nerves such as the intercostal nerves or nerves passing through a nerve plexus, which comprise trunks that divide by divisions and / or cords into branches, comprise “nerves of passage.”

Owner:NDI MEDICAL

Systems and methods to place one or more leads in tissue to electrically stimulate nerves to treat pain

ActiveUS20120290055A1Treat painOptimize locationInternal electrodesExternal electrodesElectricitySpinal column

It has been discovered that pain felt in a given region of the body can be treated, not by motor point stimulation of muscle in the local region where pain is felt, but by stimulating muscle spaced from a “nerve of passage” in a region that is superior (i.e., cranial or upstream toward the spinal column) to the region where pain is felt. Spinal nerves such as the intercostal nerves or nerves passing through a nerve plexus, which comprise trunks that divide by divisions and / or cords into branches, comprise “nerves of passage.”

Owner:SPR THERAPEUTICS

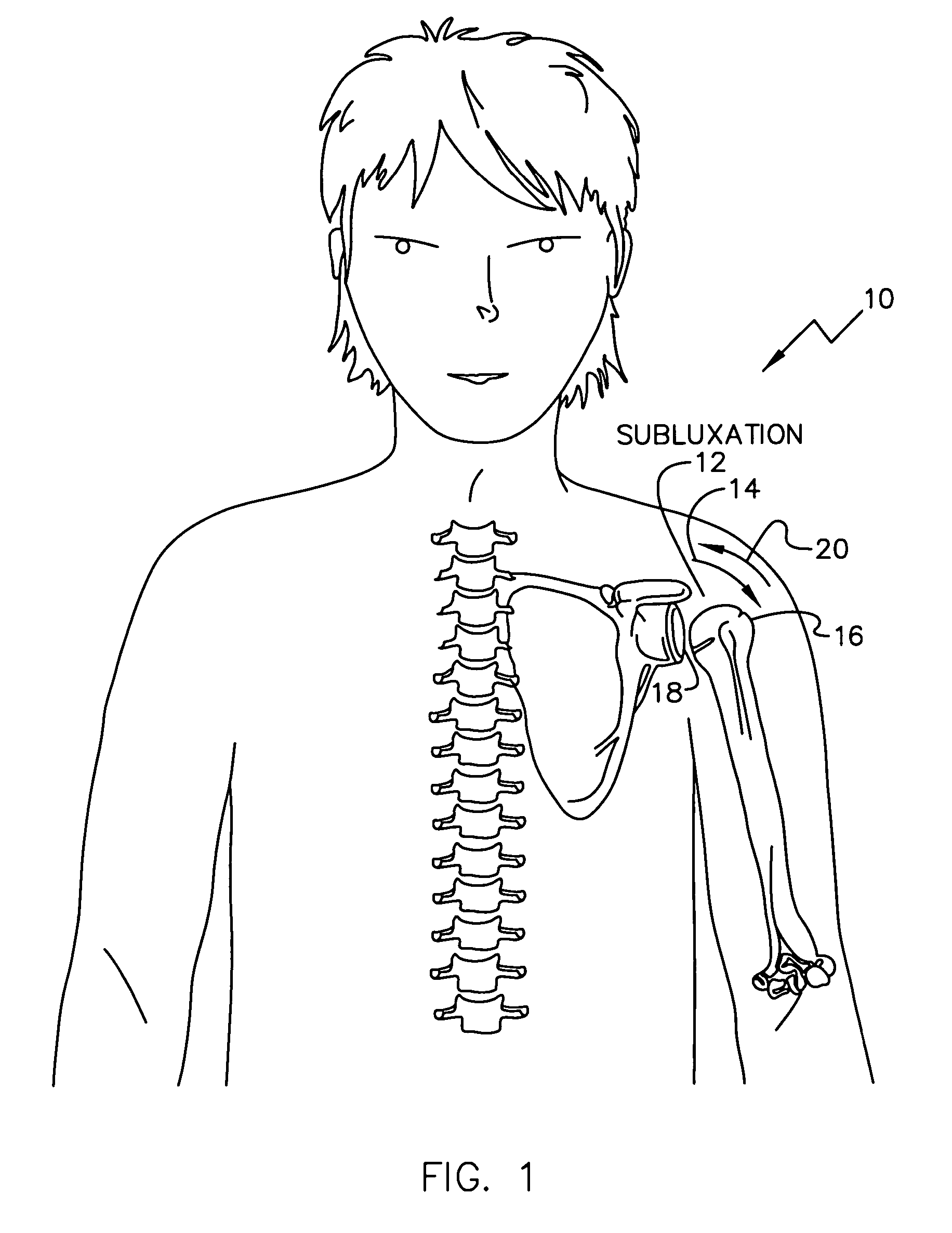

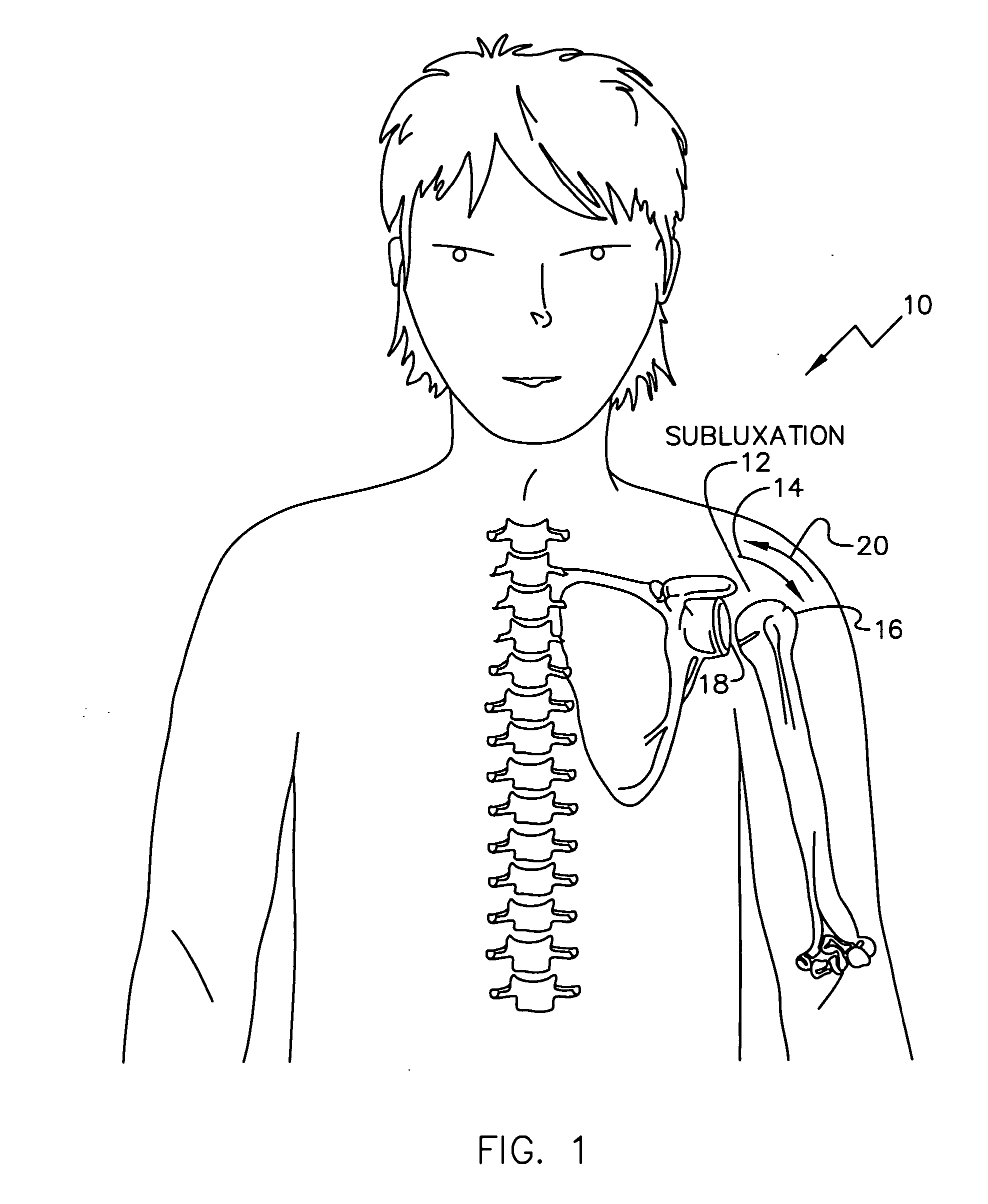

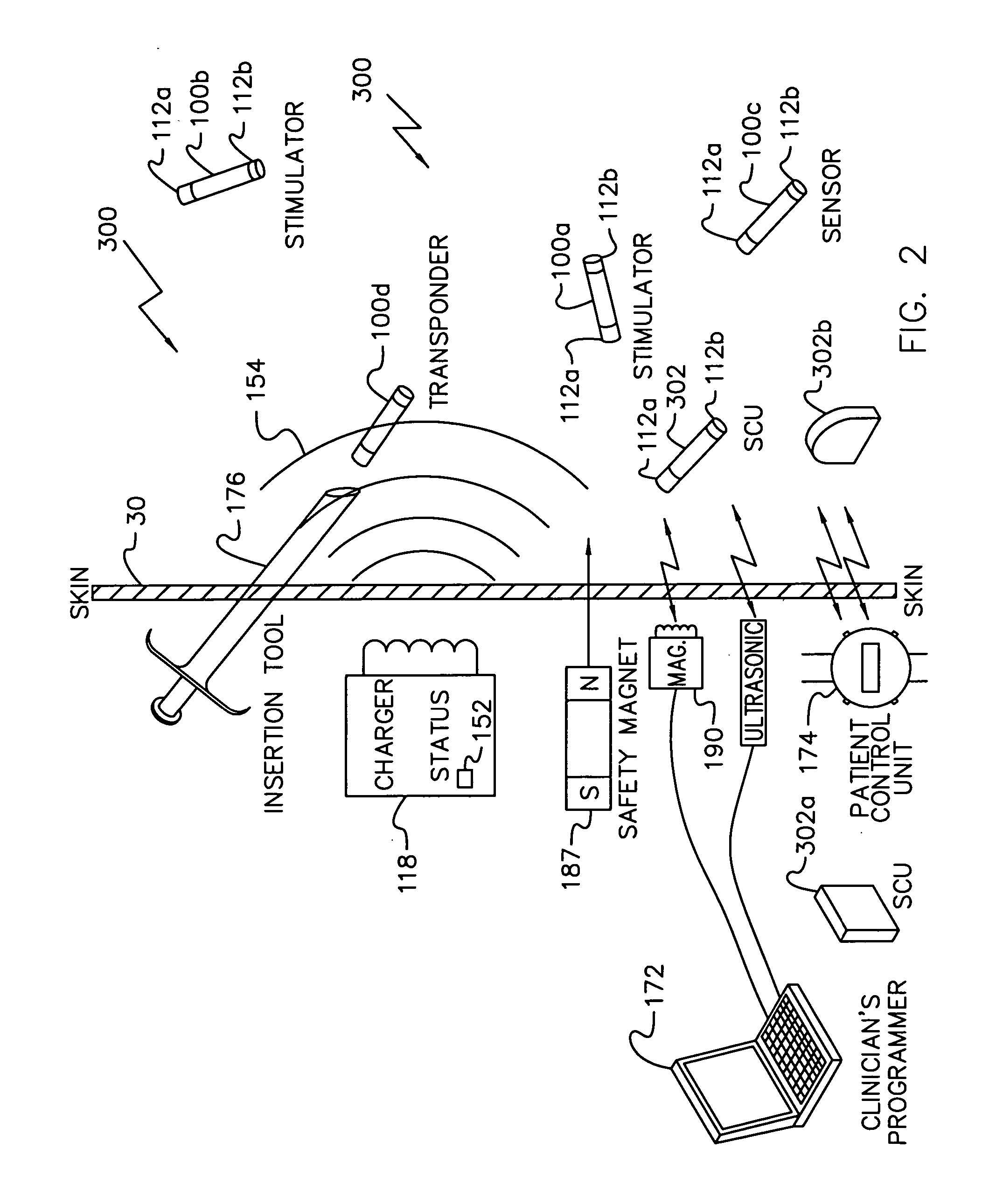

Electrical treatment to treat shoulder subluxation

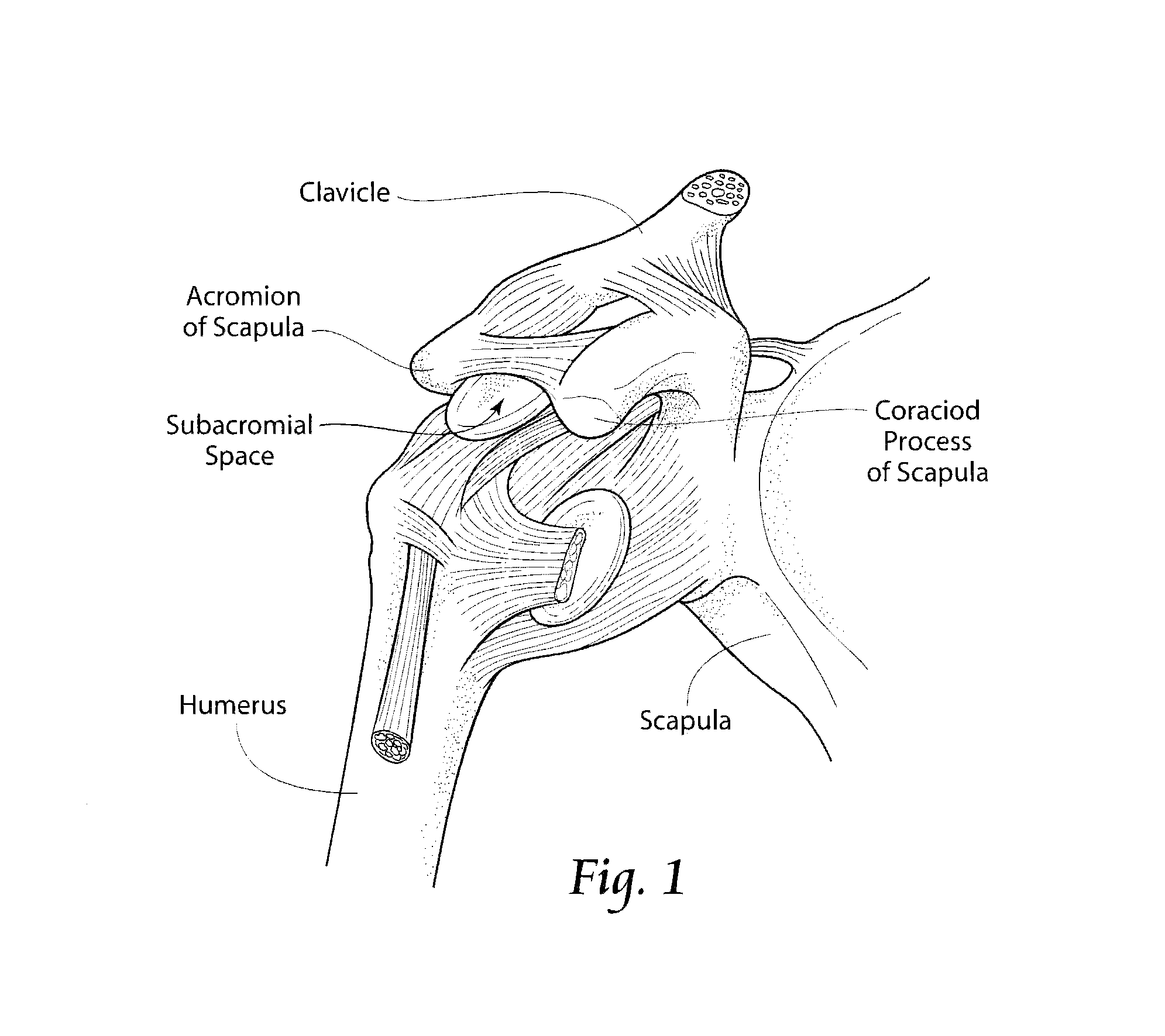

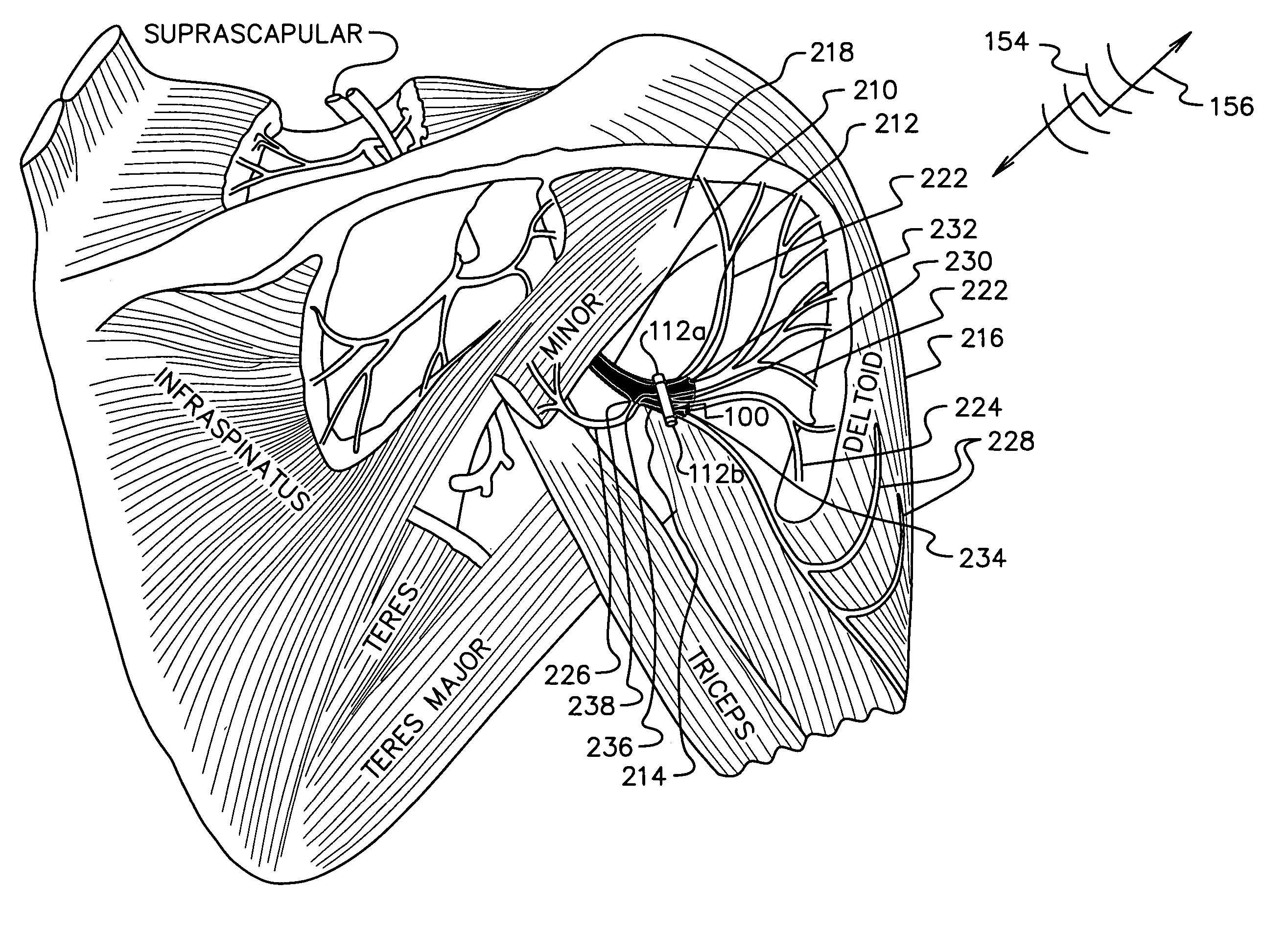

A method for treating shoulder subluxation using an implantable device to stimulate the axillary nerve which in turn activates sensory fibers to relieve shoulder pain and activates deltoid muscle to treat disuse atrophy and possibly augment any weakened voluntary movements. Known stimulation devices are either (1) external requiring surface electrodes or (2) implantable located directly into the deltoid muscle allowing stimulation of the proximate motor-points; each requiring relatively large stimulus currents and neither directly dealing with the pain resulting from the shoulder subluxation. In the present invention, a device is implanted via injection or open surgery proximate to the axillary nerve. Advantageously, the nerve branches into portions that stimulate the deltoid muscle and pass sensory signals. By stimulating the axillary nerve (1) a lower stimulus signal level can be used and (2) pain may be blocked while treating the atrophied deltoid muscle and augmenting weakened voluntary movements.

Owner:ALFRED E MANN FOUND FOR SCI RES

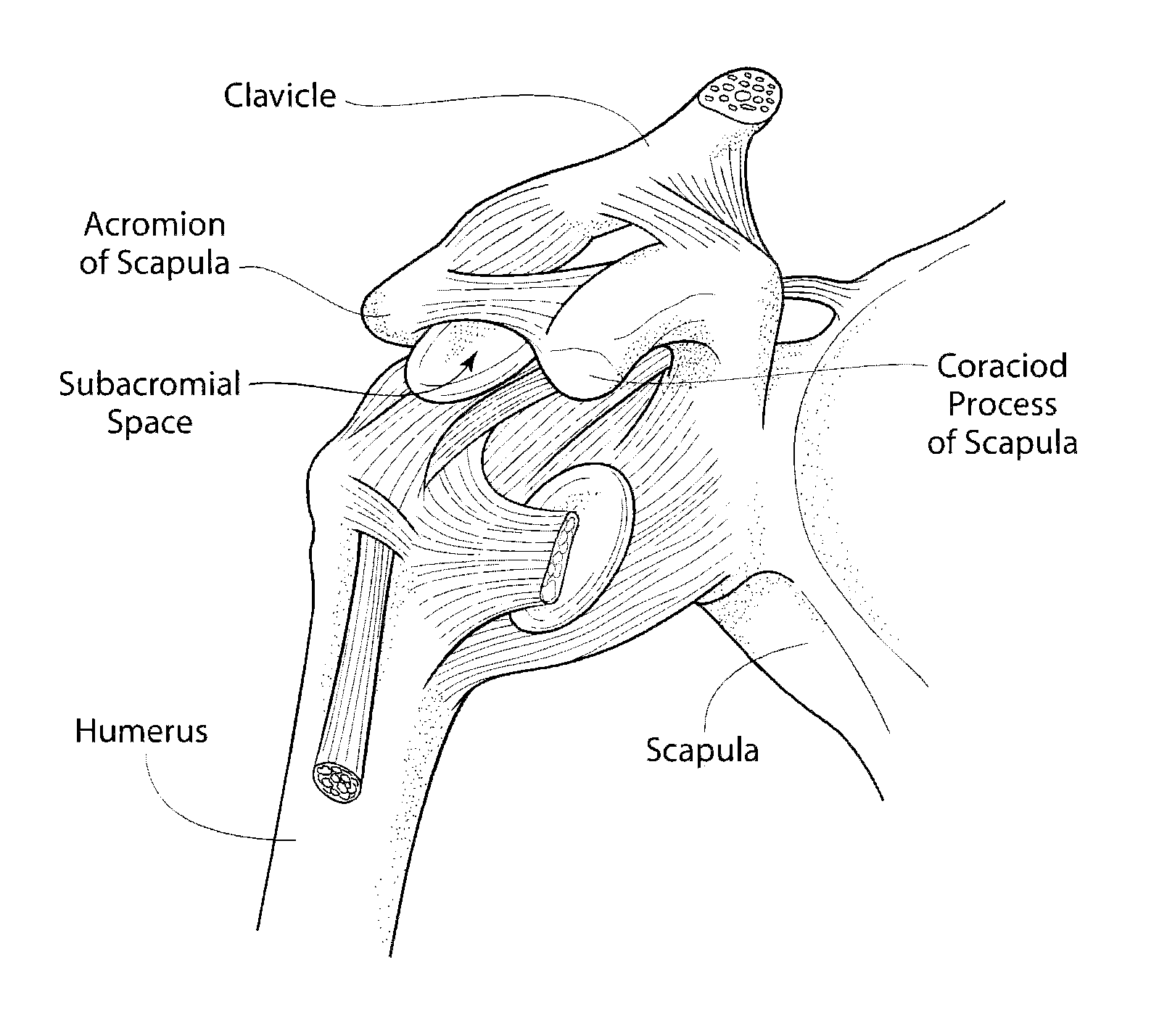

System and method for treating shoulder pain related to subacromial impingement syndrome

ActiveUS8886337B2Spinal electrodesSurgical instruments for heatingSubacromial impingementRight deltoid muscle

Systems and methods are provided for treating chronic pain occurring secondarily to subacromial impingement syndrome in a human body. A system is provided to deliver percutaneous electrical stimulation through at least one electrode to neurological motor points of the posterior and middle deltoid muscles to mediate such pain. One-time, continued and / or periodic dosing of treatment methods according to the present invention may result in a change to central nervous system maladaptive neuroplasticity.

Owner:SPR THERAPEUTICS

Systems and methods to place one or more leads in tissue to electrically stimulate nerves of passage to treat pain

Owner:NDI MEDICAL

Systems and methods to place one or more leads in muscle for providing electrical stimulation to treat pain

InactiveUS8626302B2Relief the painPain reliefInternal electrodesExternal electrodesElectricityPhysical therapy

Systems and methods are adapted to provide the relief of pain. The systems and methods make possible the percutaneous placement of one or more intramuscular leads, without the need for fluoroscopy, for providing electrical stimulation to activate a motor point innervating the muscle, to provide the therapeutic relief of pain. The one or more intramuscular leads may be placed in muscle(s) to resist migration. The target nerves and their motor points innervate the muscles in which the one or more leads are placed. The systems and methods can include a two-stage solution. The first stage may include temporary systems and methods, including the use of an external pulse generator. The second stage may include more permanent systems and methods, including the use of an implanted pulse generator.

Owner:SPR THERAPEUTICS

System and method for treating shoulder pain related to subacromial impingement syndrome

ActiveUS20140046416A1Spinal electrodesSubcutaneous electrodesSubacromial impingementRight deltoid muscle

Systems and methods are provided for treating chronic pain occurring secondarily to subacromial impingement syndrome in a human body. A system is provided to deliver percutaneous electrical stimulation through at least one electrode to neurological motor points of the posterior and middle deltoid muscles to mediate such pain. One-time, continued and / or periodic dosing of treatment methods according to the present invention may result in a change to central nervous system maladaptive neuroplasticity.

Owner:SPR THERAPEUTICS

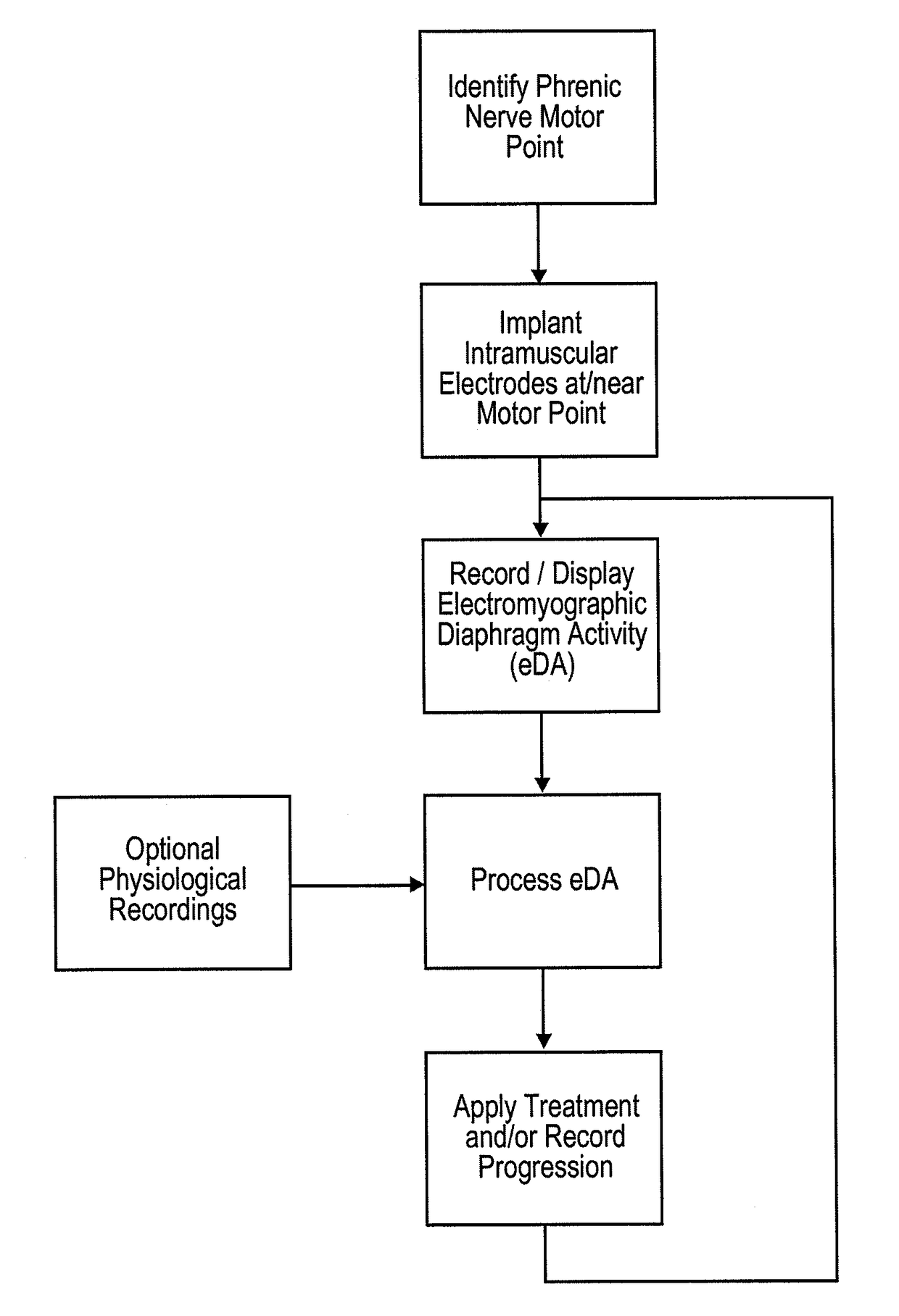

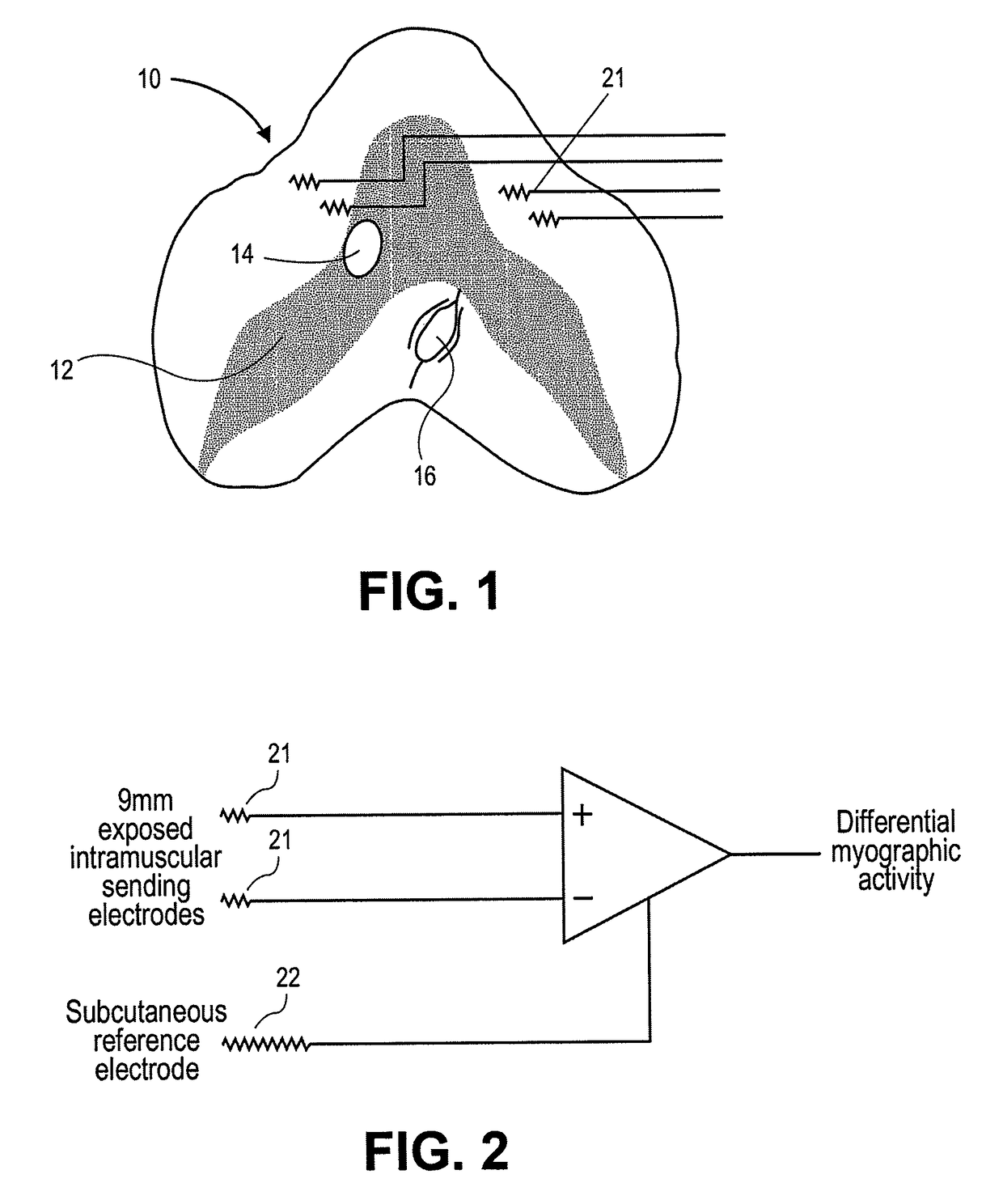

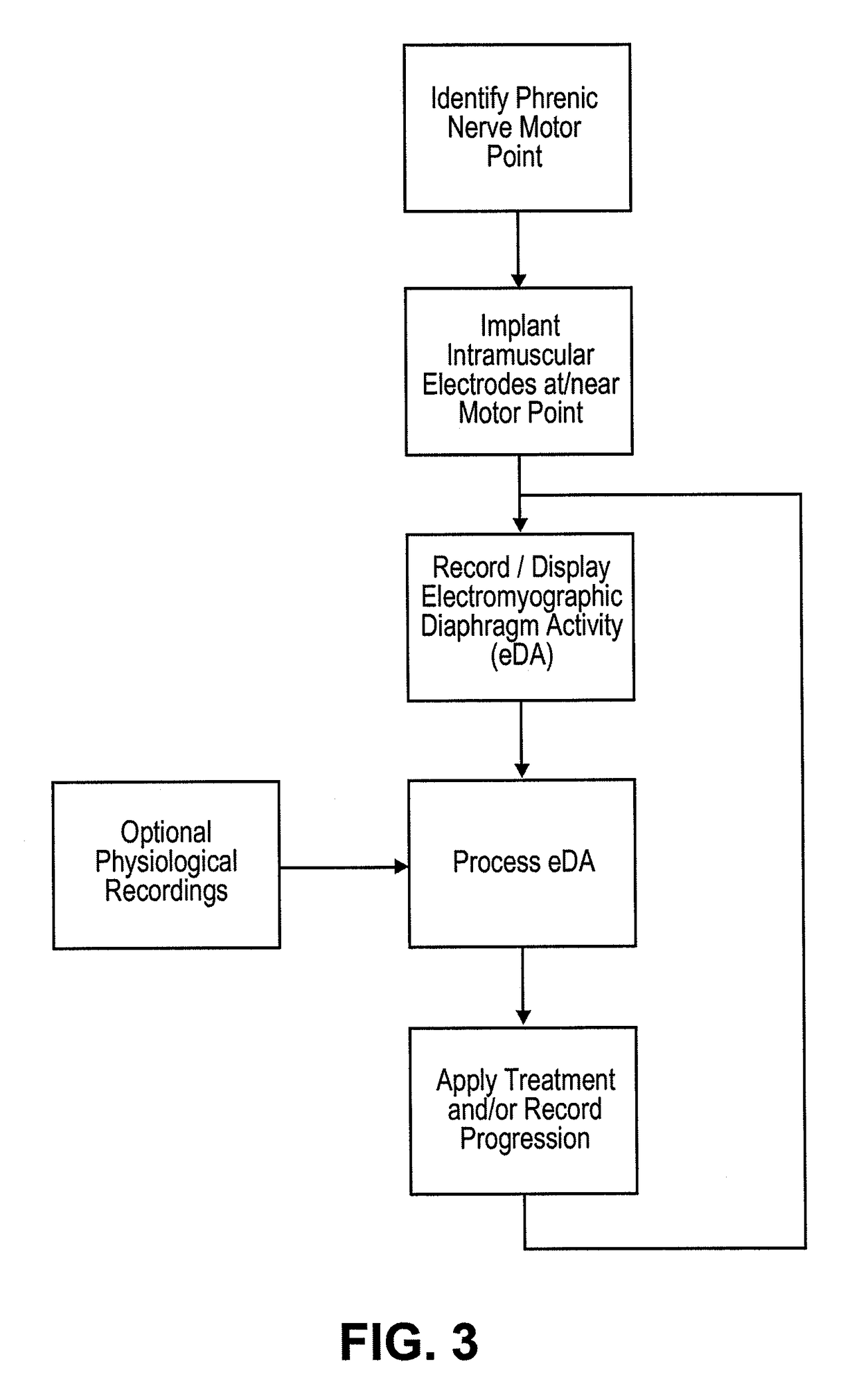

Devices and methods for assessing motor point electromyogram as a biomarker

ActiveUS20080287820A1Effectiveness of treatmentWeakening of the diaphragmElectrotherapyElectromyographyActivity indexPhysical therapy

Owner:SYNAPSE BIOMEDICAL INC

Electrical treatment to treat shoulder subluxation

InactiveUS20050245989A1Relief the painTreated conditionElectrotherapyArtificial respirationShoulder subluxationShoulder region pain

A method for treating shoulder subluxation using an implantable device to stimulate the axillary nerve which in turn activates sensory fibers to relieve shoulder pain and activates deltoid muscle to treat disuse atrophy and possibly augment any weakened voluntary movements. Known stimulation devices are either (1) external requiring surface electrodes or (2) implantable located directly into the deltoid muscle allowing stimulation of the proximate motor-points; each requiring relatively large stimulus currents and neither directly dealing with the pain resulting from the shoulder subluxation. In the present invention, a device is implanted via injection or open surgery proximate to the axillary nerve. Advantageously, the nerve branches into portions that stimulate the deltoid muscle and pass sensory signals. By stimulating the axillary nerve (1) a lower stimulus signal level can be used and (2) pain may be blocked while treating the atrophied deltoid muscle and augmenting weakened voluntary movements.

Owner:ALFRED E MANN FOUND FOR SCI RES

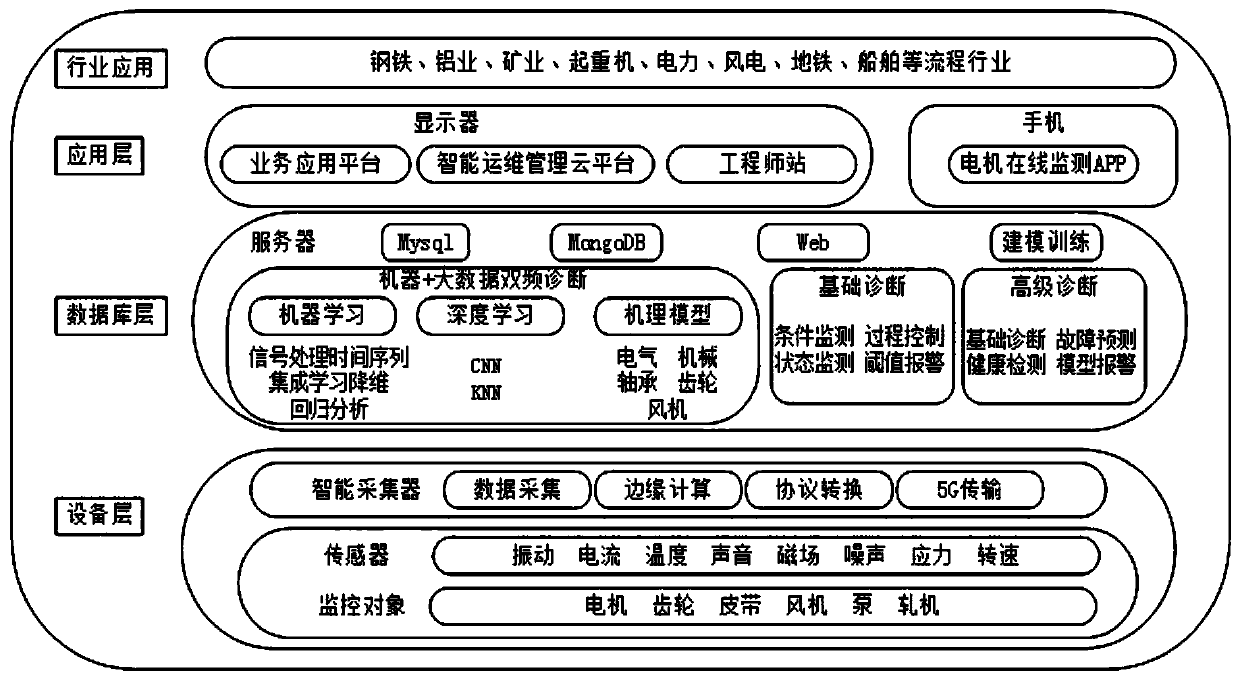

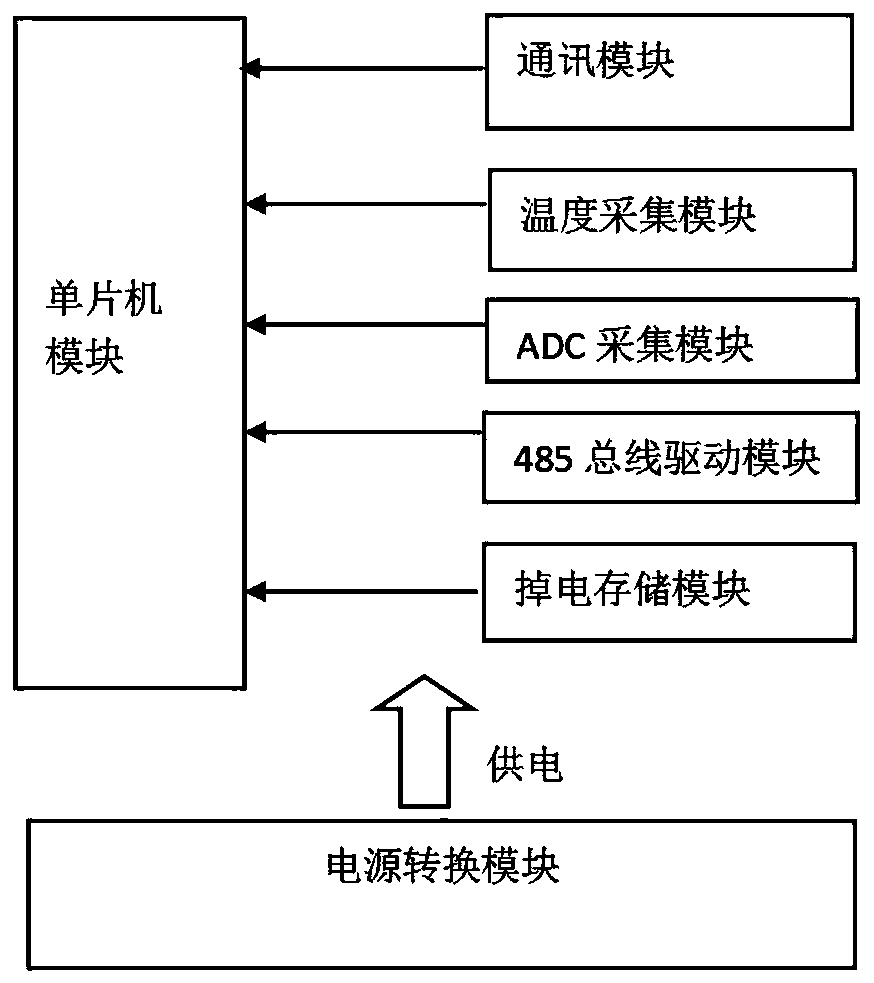

Motor full-life-cycle management and control system

PendingCN110728443ASolve the problem of high labor costsEasy to useDigital data information retrievalForecastingLiquid crystalServer

A motor full-life-cycle management and control system comprises a server, a liquid crystal screen and an equipment full-life-cycle management and control system, and the equipment full-life-cycle management and control system comprises a service application platform, an engineer station, an intelligent operation and maintenance management cloud platform and a motor online monitoring APP; the service application platform is used for displaying a motor state curve in real time, has the functions of addition, deletion, modification and inspection of equipment data, expert diagnosis, motor point inspection and maintenance management, and opens required corresponding functions for different users; the intelligent operation and maintenance management cloud platform is used for fault prediction analysis, health state tracking management, mechanism big data double-frequency calculation, online machine learning training model and unit coupling operation data analysis; the method can find out that the degradation trend of the motor has urgent demands in advance, achieves the scientific prediction and pre-judgment of the motor fault after obtaining the current, temperature and vibration parameter data of the motor through the intelligent means of intelligent monitoring of the motor, reduces the cost, reduces the manpower, provides equipment guarantee, and improves the production efficiency.

Owner:鞍钢集团自动化有限公司

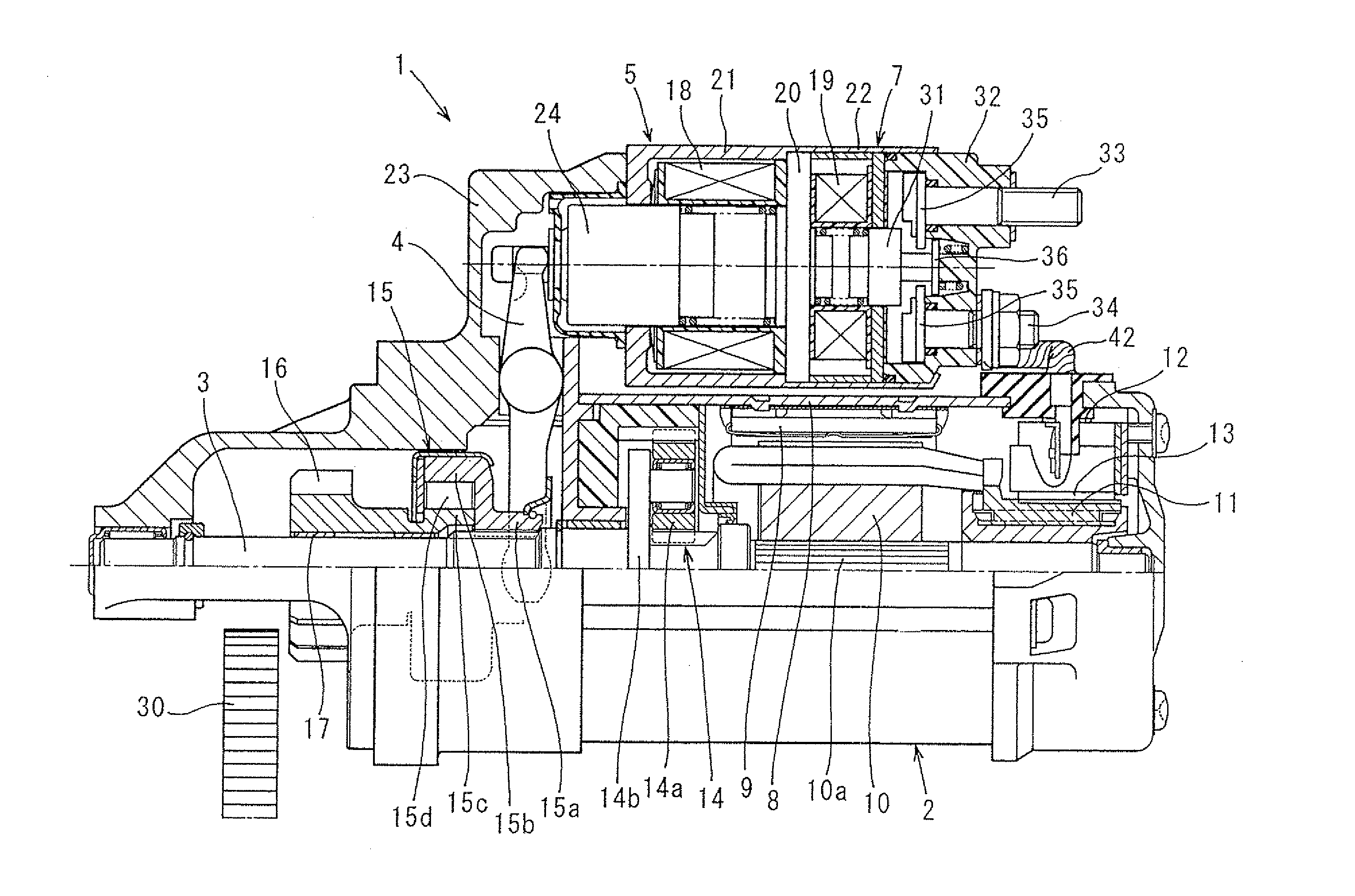

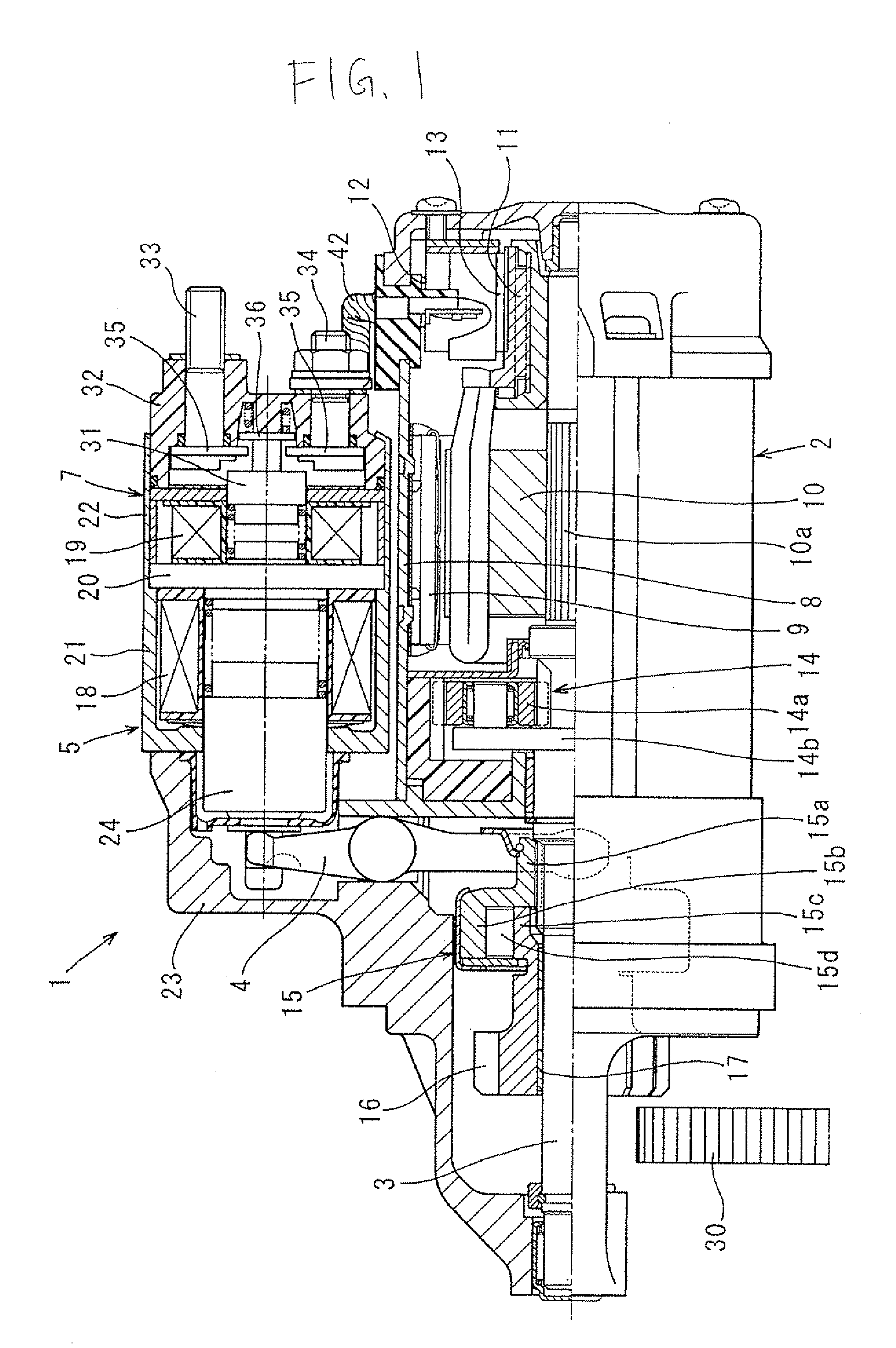

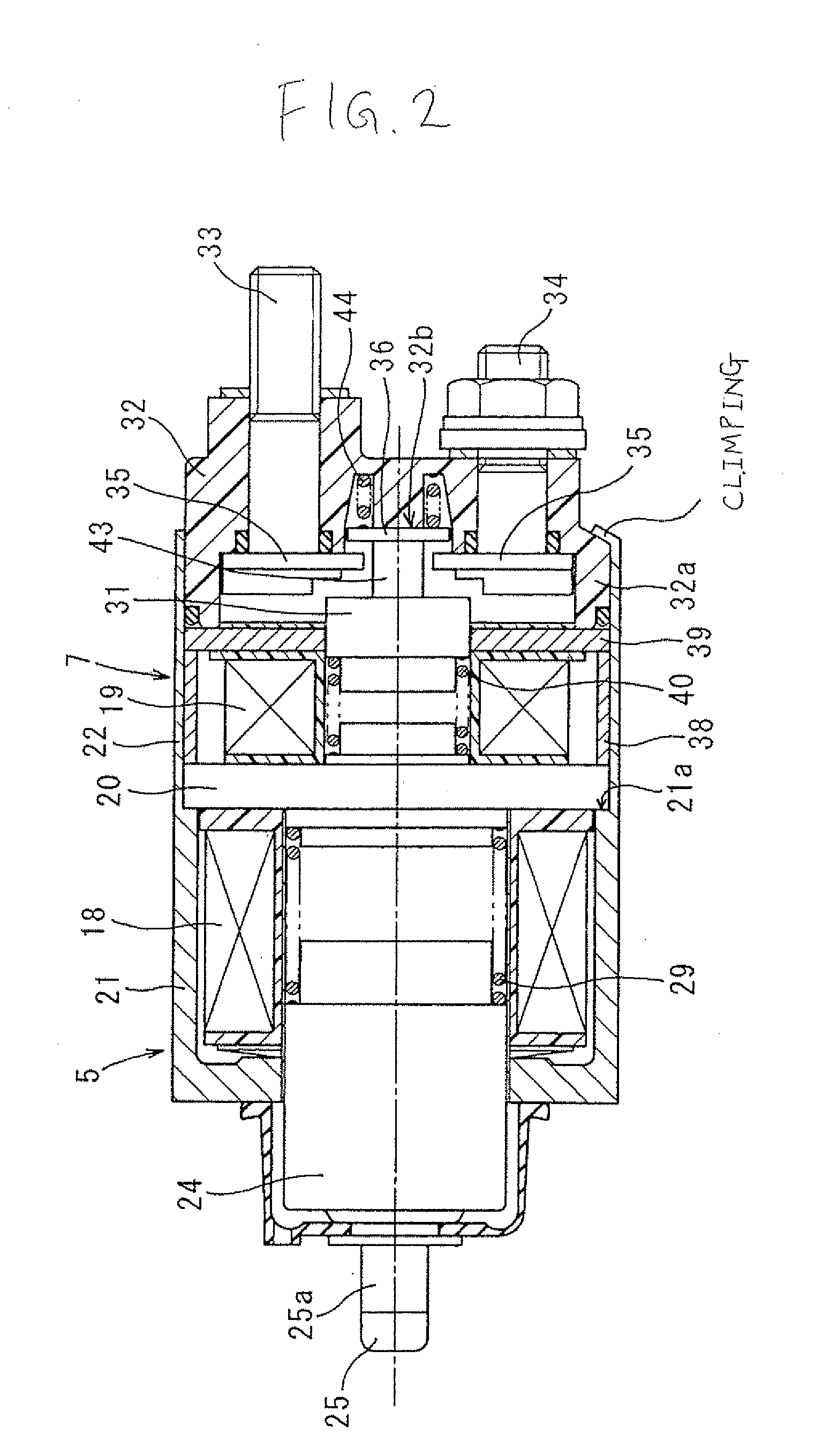

Starter for vehicles

ActiveUS20100264764A1Improve the ease of assemblyReduce in quantityPower operated startersElectric motor startersEngineeringPinion

A solenoid for pushing out a pinion pushes out a pinion gear to a ring gear side and a switch for motor energization that opens and closes a motor point of contact have a solenoid coil and a switch coil that form an electromagnet by energization, respectively. A fixed iron core used commonly by both coils is arranged between the solenoid coil and the switch coil. A solenoid yoke that covers a perimeter of the solenoid and a switch yoke that covers a perimeter of the switch are formed integrally as a whole yoke in an axial direction.

Owner:DENSO CORP

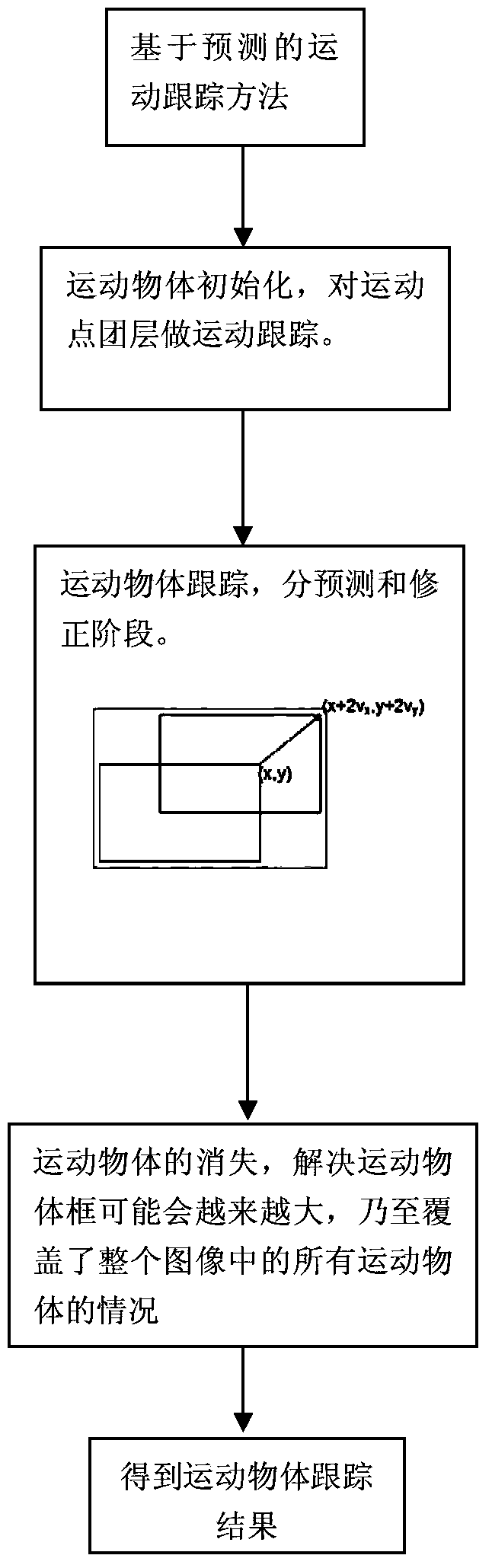

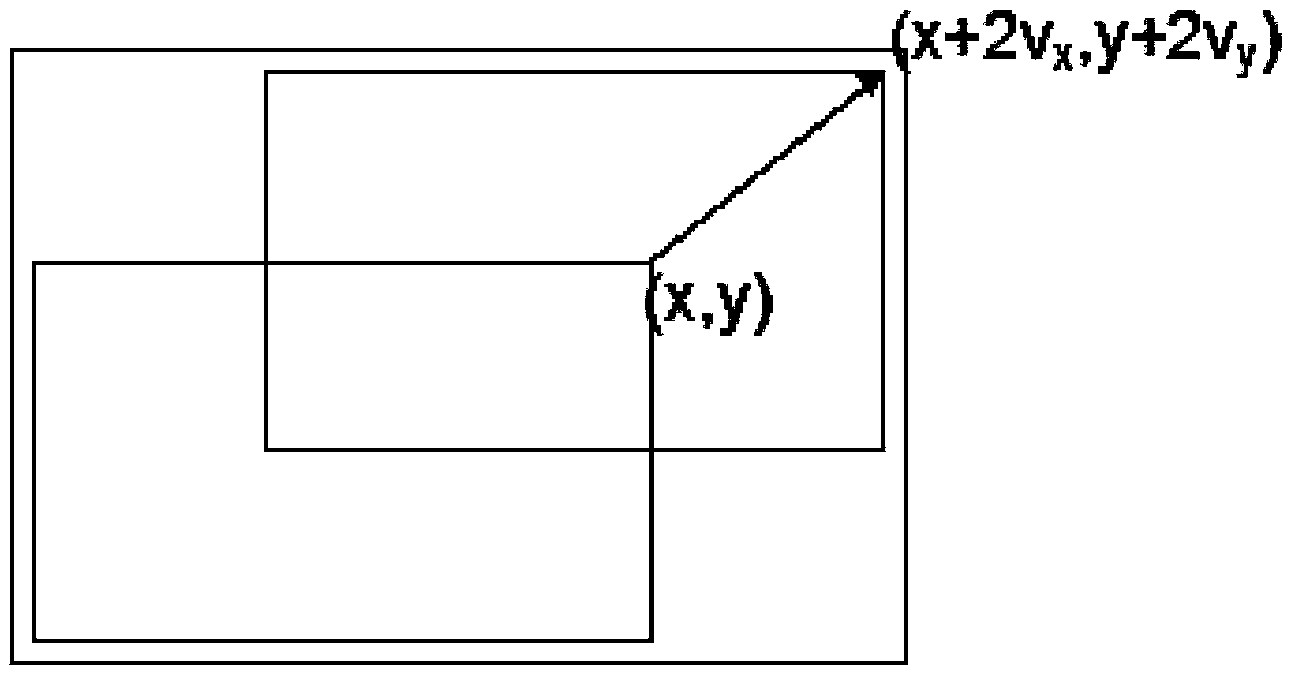

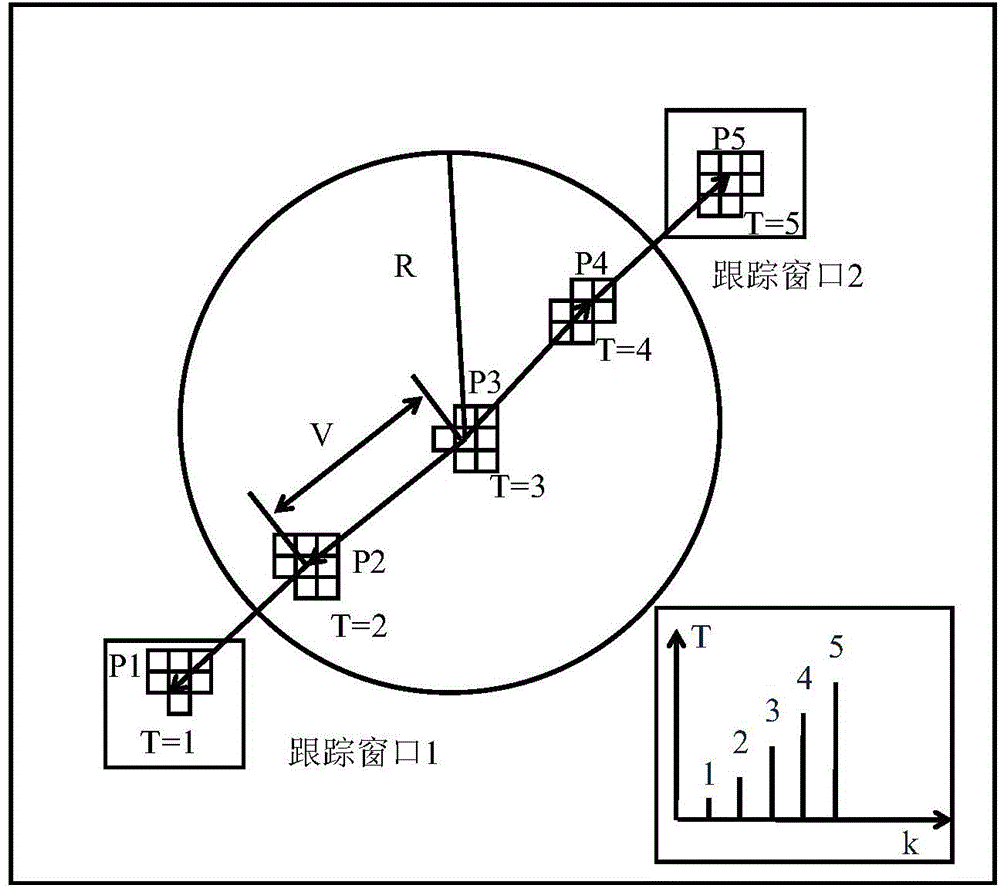

Method for motion tracking based on predication

InactiveCN103839276AEasy to trackAccurate separationImage analysisComputer graphics (images)Correction method

The invention discloses a method for motion tracking based on predication. The method comprises the following steps that movable objects are initialized and motion tracking is conducted on a motor point cluster layer; the movable objects are tracked, the position of each movable object at the current moment is predicated according to the position of the movable object at the last moment in a predication stage, and which movable objects current frame motor point clusters belong are found in a correction stage; the movable objects disappear and the target change trend is corrected. Due to the fact that the motor point clusters are tracked through the prediction method and the correction method, the problem that one movable object is divided into multiple communication zones when the prediction position of the movable object is searched for the motor point clusters is solved. Due to the fact that motion tracking based on predication is adopted in the method, the defects that the tracking mode of a Kalman filtering system is large in calculated amount and can not be well adapted to actual motion change are overcome and a clear result of complex movable object tracking can be obtained.

Owner:DALIAN LINGDONG TECH DEV

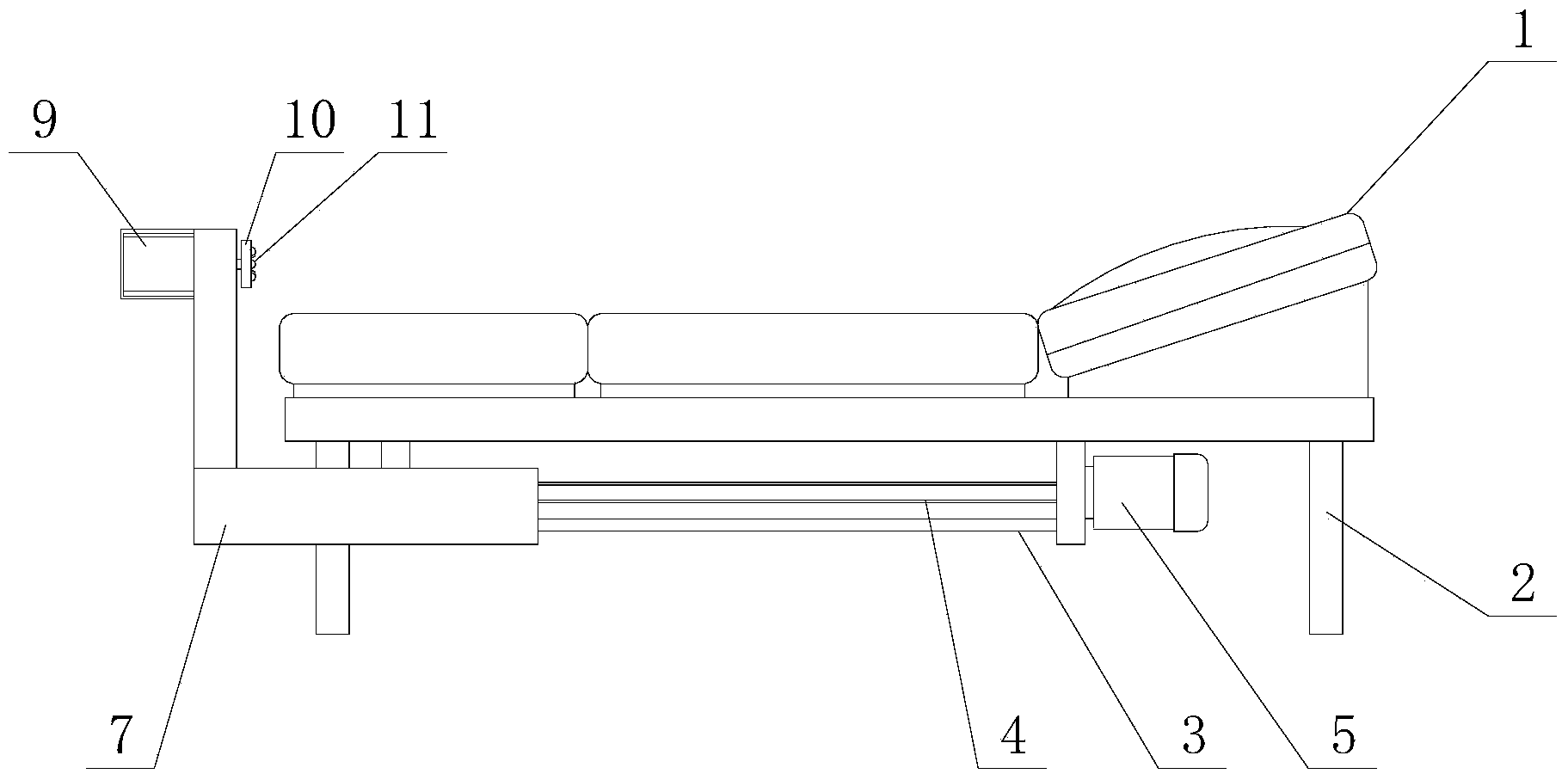

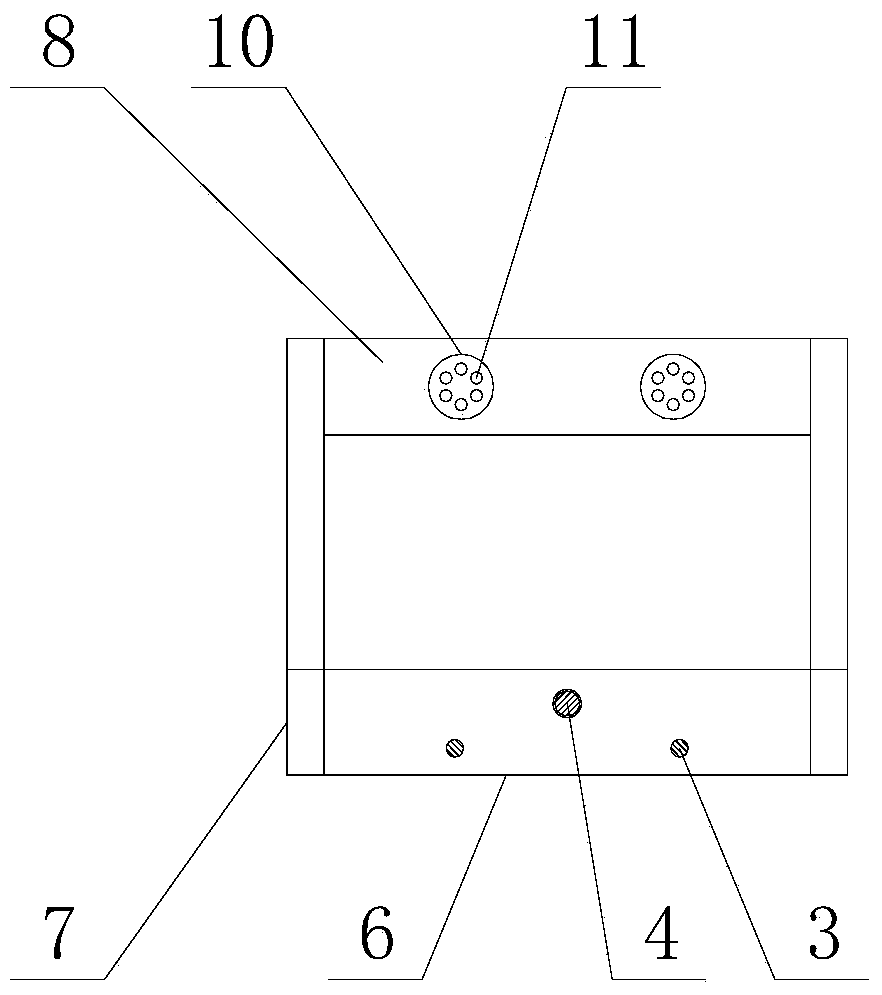

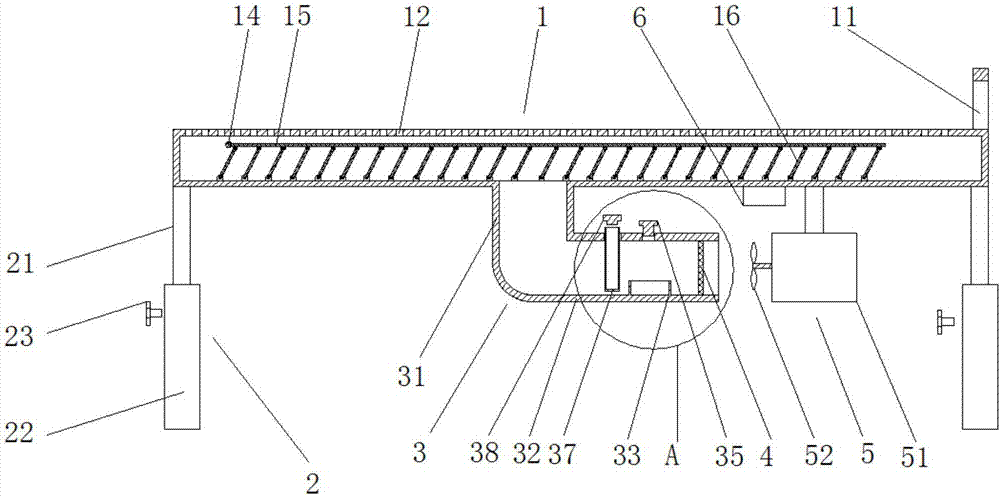

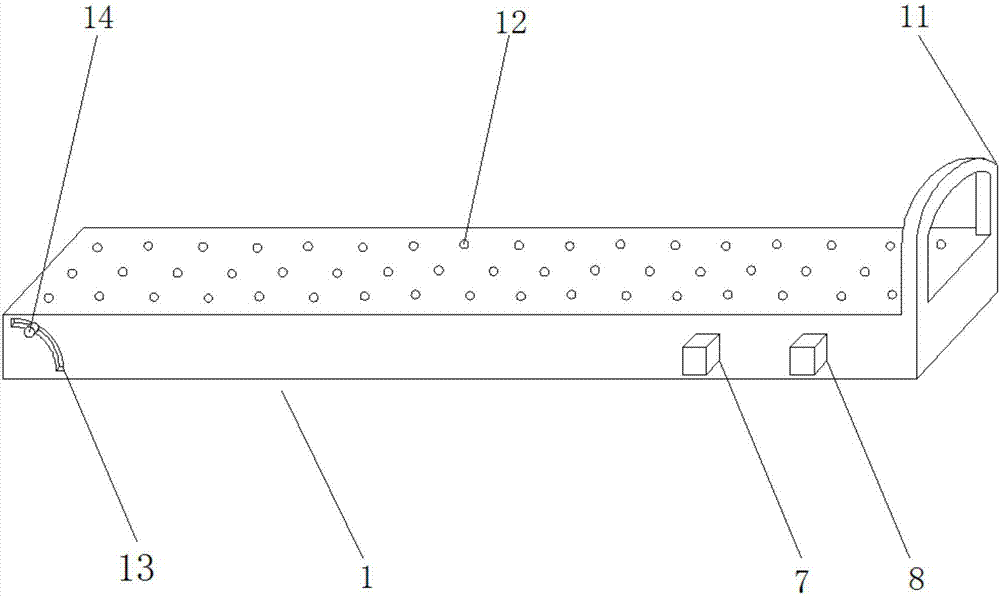

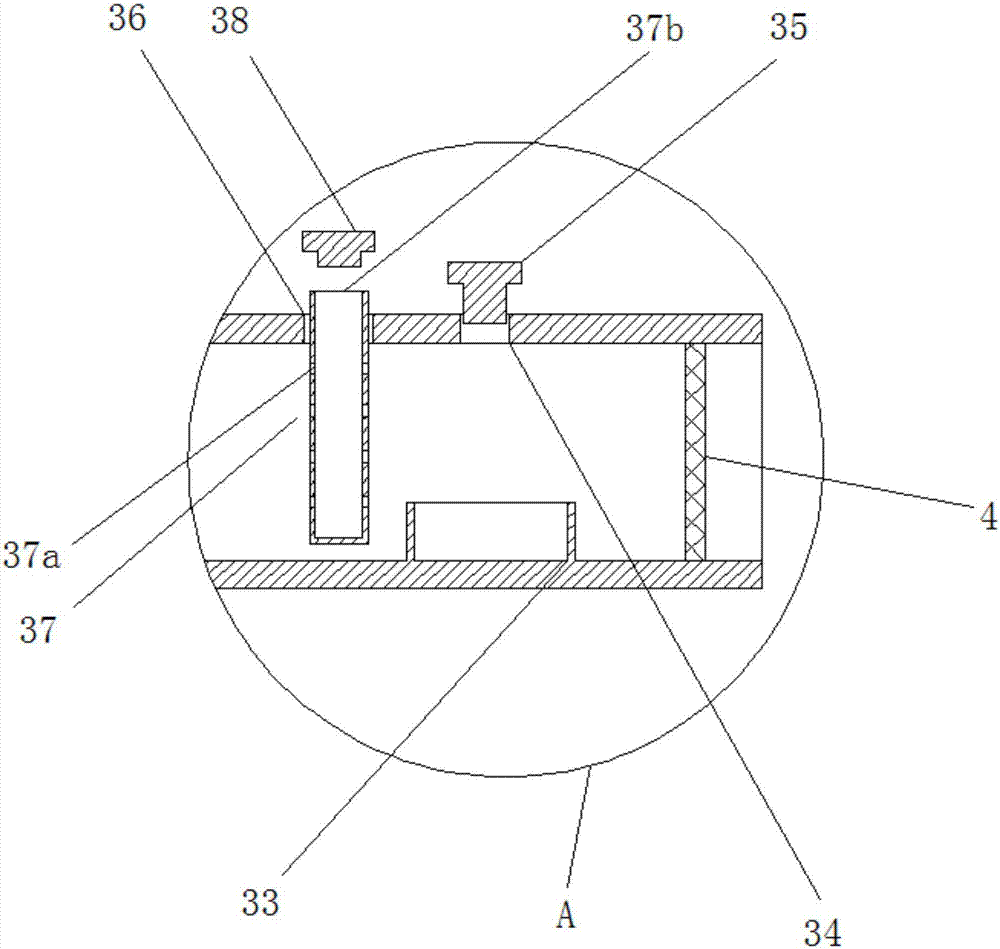

Massage physiotherapy couch

The invention relates to a massage physiotherapy couch which comprises a couch body and a couch bracket, wherein a guide rod and a screw rod are mounted on the couch bracket, and positioned below the couch body; one end of the screw rod is connected with a mobile driving motor; the axis of the screw rod is parallel to that of the guide rod; the screw rod and the guide rod are arranged horizontally in the front and rear direction of the couch body; a slide block is arranged on the screw rod and the guide rod; two ends of the slide block are respectively connected with L-shaped brackets; the two L-shaped brackets are respectively positioned on two sides of the couch body; cross arms positioned above the couch body are connected onto the L-shaped brackets; at least one massage driving motor is mounted on each cross arm, and provided with an output shaft; one end of the output shaft of the massage driving motor points to the front end of the couch body; the axis of the output shaft of the massage driving motor is arranged horizontally; crystal massage heads are mounted on massage plates. The massage physiotherapy couch can massage feet of a human body to enable the functions of the physiotherapy couch to be more complete, and the crystal massage heads are adopted as massage components, so that the massage effect is better.

Owner:TIANJIN WEIDAN TRADING

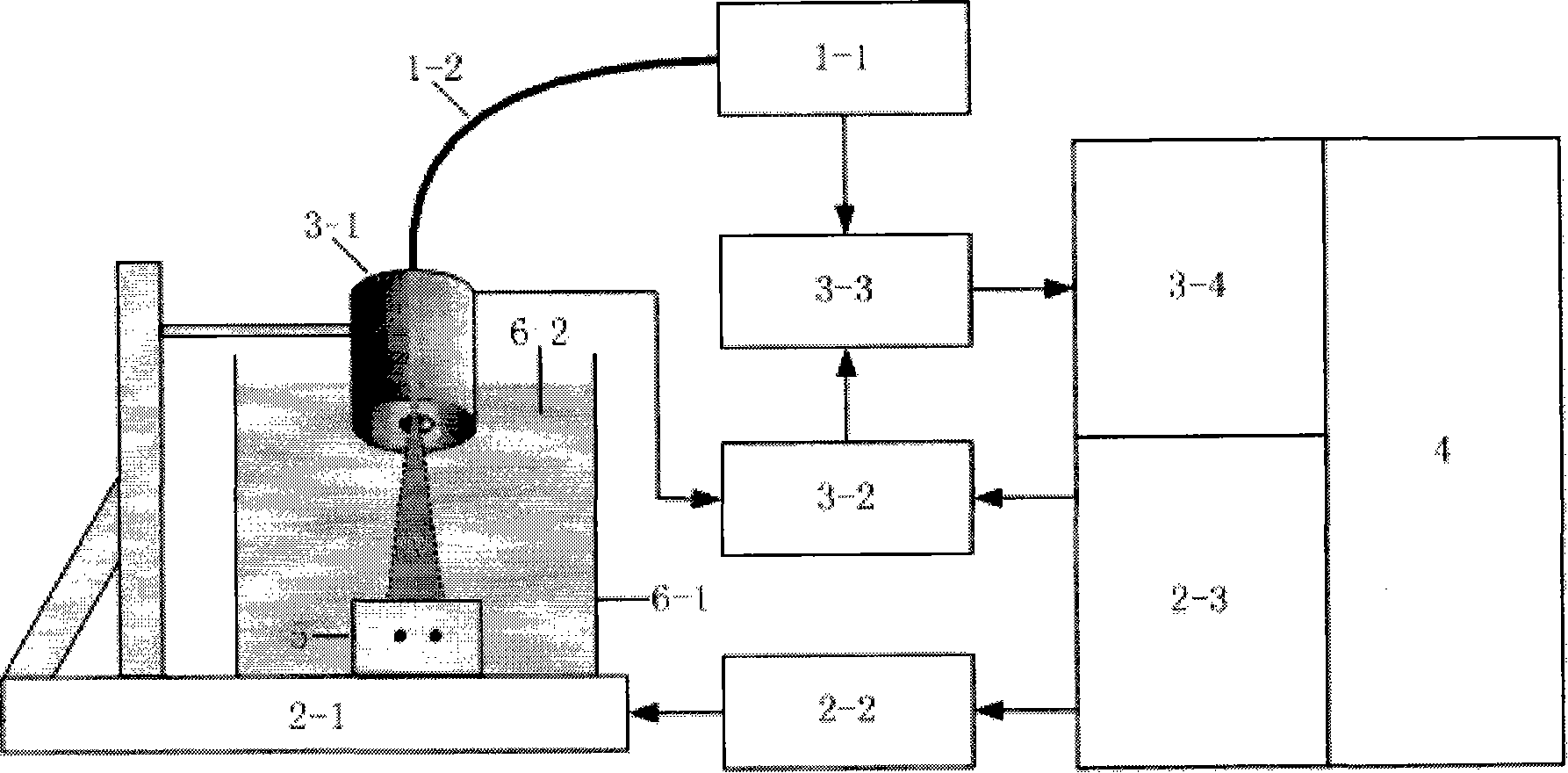

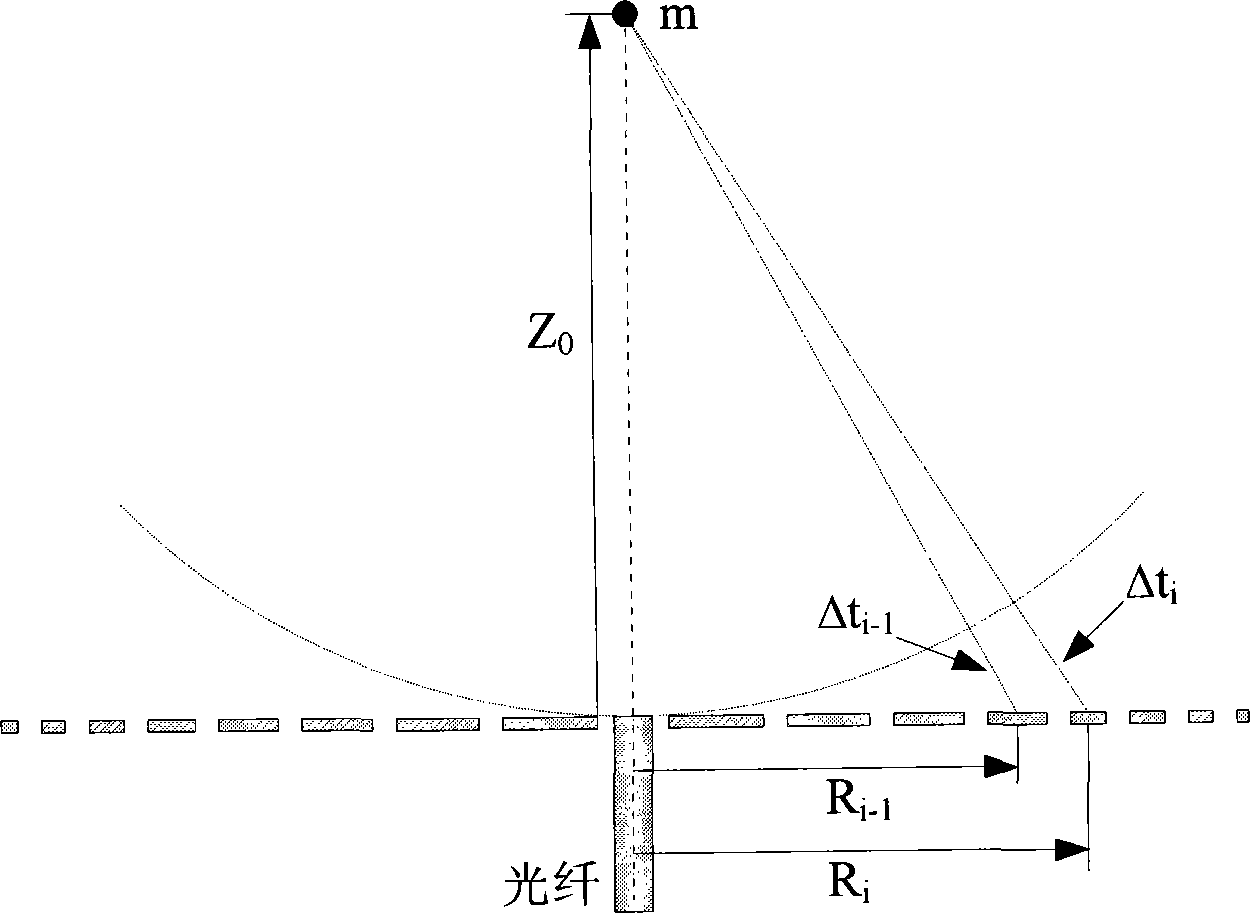

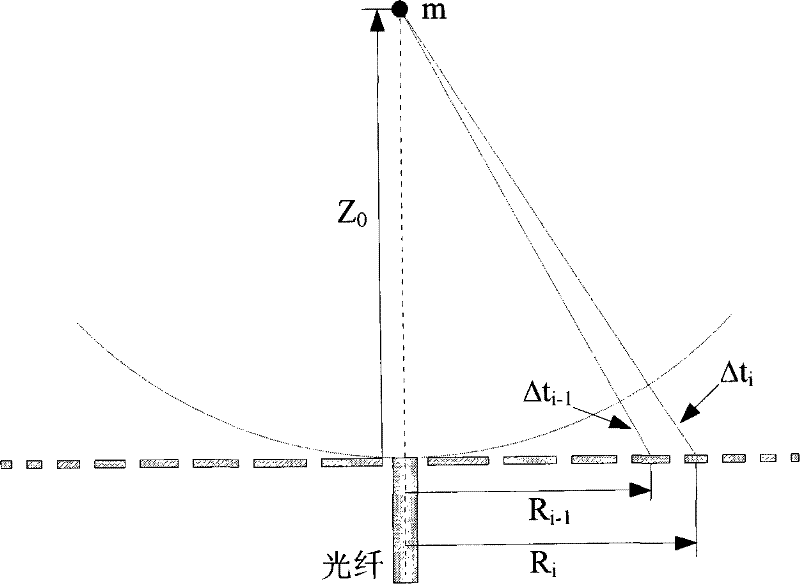

Dorsal mode light acoustic imaging method based on multiple phase control focusing ring array

InactiveCN101251514AImprove signal-to-noise ratioImprove imaging resolutionUltrasonic/sonic/infrasonic wave generationOperabilityData treatment

The invention provides a multiple phase control focus ring array-based dorsad mode optical acoustic imaging method; steps of the method are as follows: (1) the pulsed laser is used to irradiate a sample to be tested; (2) the sample to be tested or a multi-ring array detector receives optical acoustic signals by the dorsad mode of a step motor driving scan, and simultaneously acquires the data of optical acoustic signals; (3) data processing software is used to calculate the phase control of the acquired optical acoustic signals for realizing the dynamic focus mode A scan in the depth Z direction, and by the two-dimensional data scanning in the X-Y direction of the step motor point-to-point, a three-dimensional optical absorption distribution map can be synthesized by the back projection. The method has the advantages that due to the adoption of the multi-ring array detector, the super narrow aperture angle and the good direction pointing of the multi-ring array detector greatly improve the imaging resolution, and realize the focus scan imaging in both X and Y directions; due to the adoption of the calculation phase control focus technology, the signal to noise ratio of signals can be effectively improved, and the mode A dynamic focus scan imaging in the depth Z direction can be realized; due to the receiving of optical acoustic signals in the dorsad mode, the operability and the application range of the system are greatly improved.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Systems and methods to place one or more leads in tissue to electrically stimulate nerves to treat pain

ActiveUS10668285B2Reduce distanceInternal electrodesExternal electrodesSpinal columnPhysical medicine and rehabilitation

It has been discovered that pain felt in a given region of the body can be treated, not by motor point stimulation of muscle in the local region where pain is felt, but by stimulating muscle spaced from a “nerve of passage” in a region that is superior (i.e., cranial or upstream toward the spinal column) to the region where pain is felt. Spinal nerves such as the intercostal nerves or nerves passing through a nerve plexus, which comprise trunks that divide by divisions and / or cords into branches, comprise “nerves of passage.”

Owner:SPR THERAPEUTICS

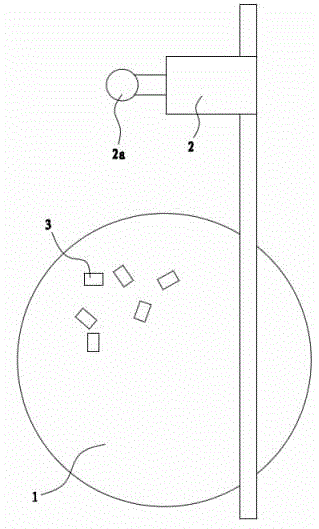

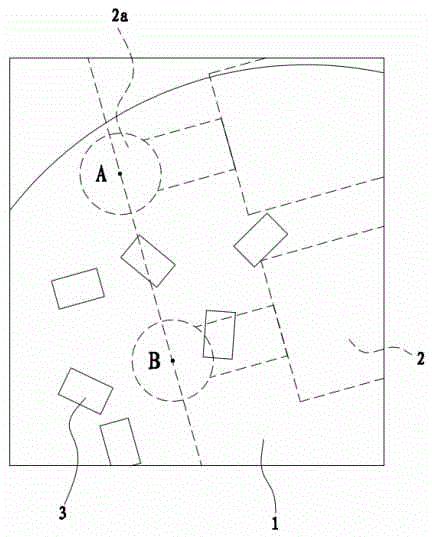

Method and system for locating gaze type camera motor point goal

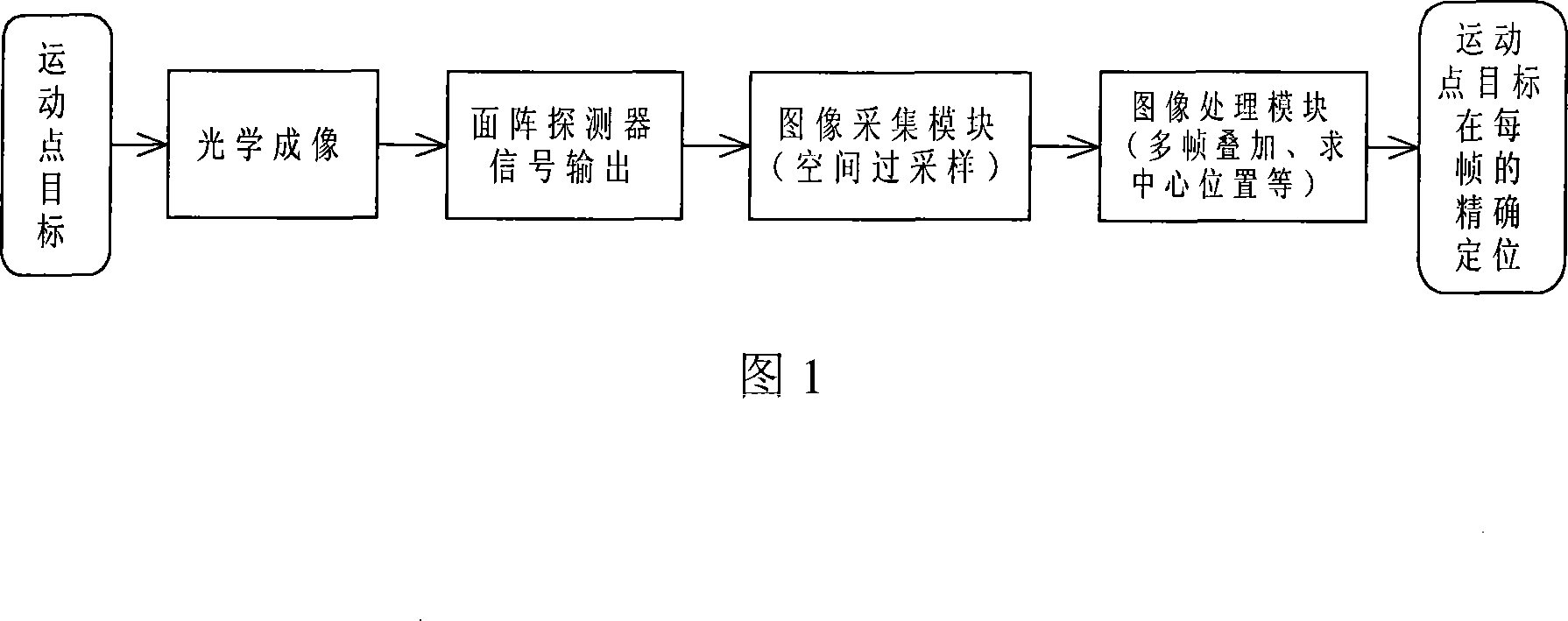

ActiveCN101226641AImprove spatial resolutionImprove signal-to-noise ratioImage analysisFlat panel detectorImaging processing

The invention discloses a target location method and a system of starting camera movement points. The target location method comprises 1 carrying out space oversampling to movement point targets by using high frame rate character of the staring camera, 2 carrying multi-frame superposition to collected sequence images, 3, on the basis of multi-frame superposition, detecting and extracting small target spots, and then acquiring the central point of the small target points with sub-pixel processing method. The system includes an optical imaging system, a flat panel detector, an image collecting module and an image processing module, wherein the image collecting module realizes space oversampling to movement point target, the image processing module carries out multi-frame superposition, aiming at collected sequence images, carries out small target spots detecting, extracting and acquires the central position of point targets with sub-pixel method and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

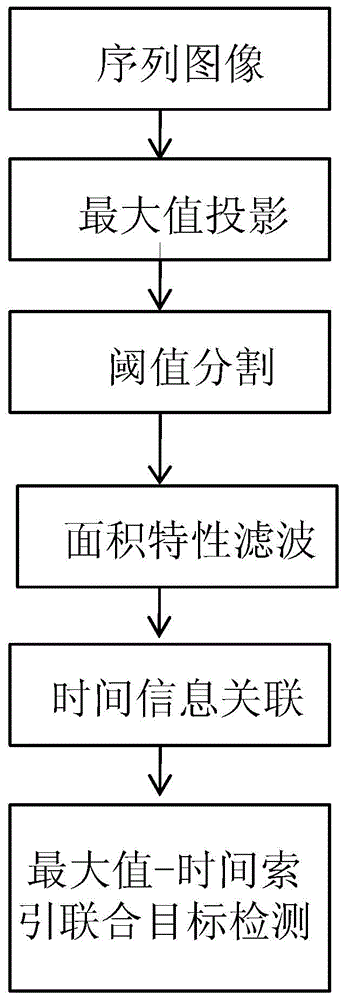

Motor point target detection method based on maximum-time index union

ActiveCN104537690AImplement schema conversionSmall amount of calculationImage enhancementImage analysisPrior informationComputer vision

The invention discloses a motor point target detection method based on maximum-time index union. The method comprises the following steps: 1) a maximum gray value projected image and a time index frame image are obtained; 2) noise filtering process is performed on the time index frame image; 3)a motor point target in the time index frame image is detected. The motor point target detection method based on the maximum-time index union can effectively detect the motion trail of dispersed punctiform targets in a sequence image and need no prior information of the targets. The calculated amount is small and the instantaneity is high.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

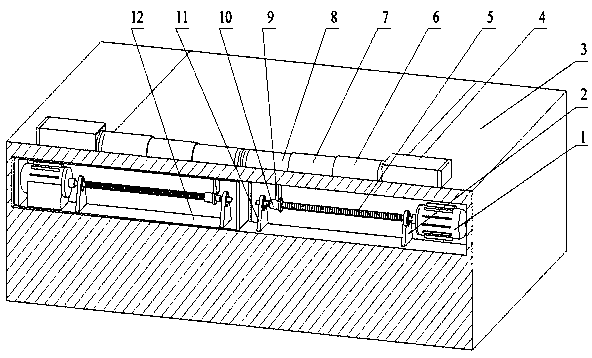

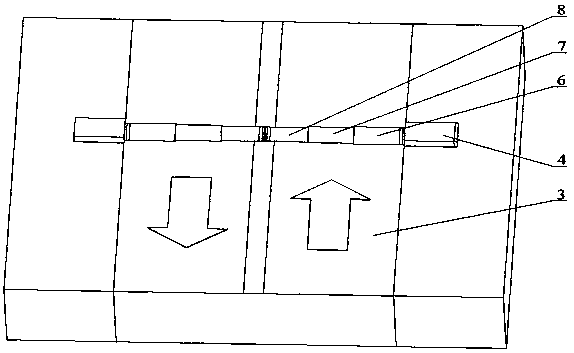

Method for calibrating full-automatic visual inspection machines for products

The invention discloses a method for calibrating full-automatic visual inspection machines for products, and belongs to the technical field of methods for calibrating machines. By the aid of the method, the problem of poor product picking effects of existing visual inspection machines can be solved. The method includes calibrating paths of linear motors and circle centers of turntables, to be more specific, A1, shifting the linear motors to first motor points according to preset displacement b1; B1, arranging a product below each sucker; C1, determining coordinates p1 of the center points of the products in visual fields of cameras; D1, shifting the linear motors to second motor points according to preset displacement b2; E1, placing a product below each sucker; F1, determining coordinates p2 of the center points of the products in the visual fields of the cameras; G1, respectively computing coordinates of origins of the linear motors, amplification factors of the cameras and the paths of the linear motors and inputting data to computers. The method has the advantage that the products can be effectively picked by the linear motors after the full-automatic visual inspection machines are calibrated by the aid of the method.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Indoor exercise device with health care effects

ActiveCN107185169AAdjust the wind directionVersatileGymnastic exercisingMedical devicesEngineeringSteaming

The invention relates to an indoor exercise device with health care effects. The device comprises a supporting plate, telescopic legs, air tubes, an electric heating wire mesh, a blowing device, a power source, a first switch and a second switch, wherein the supporting plate is a hollow rectangular body, a baffle ring is disposed on one end which is located on the upper wall of the supporting plate, and air vents are distributed uniformly in the upper wall of the supporting plate; the four telescopic legs are disposed, and the telescopic legs are disposed on four corners of the lower end face of the supporting plate; the air tubes comprise a longitudinal tube and a horizontal tube; the electric heating wire mesh is disposed on the end of the horizontal tube inner wall far from the longitudinal tube; the blowing device comprises a motor disposed under the supporting plate, an output shaft of the motor points at the horizontal tube and is flush with the axis of the horizontal tube, and a fan is disposed on the output shaft of the motor; and the power source is disposed under the supporting plate, and the first switch and the second switch are disposed on side faces of the supporting plate. According to the invention, natural air or hot air can be blown, and traditional Chinese medicines can be used for fuming and steaming.

Owner:黄萍

Device convenient for gluing

InactiveCN109397711AEasy to operateSave human effortLiquid surface applicatorsCoatingsLocking mechanismTransverse plane

The invention discloses a device convenient for gluing, which comprises a base, a motor, a lead screw, a body, an inclined stay bar and a locking mechanism, wherein a supporting plate is vertically arranged on the upper surface of one side of the base, the motor is fixedly arranged on the other side of the base, the shaft direction of the motor points to the supporting plate, the supporting plateis connected with the motor through a lead screw; the lead screw is connected with a sliding block in a threaded manner, the sliding block is cylindrical with inner the ring thereof provided with an internal thread, a supporting column is vertically fixed between the supporting plate and the motor, the center position at the back side of the body is hinged with the top end of the supporting column, one side of the inclined stay bar is hinged on the sliding block, and the other side is hinged to one side of the bottom of the body, a locking mechanism is arranged on the body and a transverse plate is internally arranged in the body, the bottom of the locking mechanism is hinged with a pressing plate, and the pressing plate moves up and down through the locking mechanism and presses against the upper surface of the transverse plate. The invented device can be conveniently operated by one person, which saves manpower.

Owner:徐州博源科技有限公司

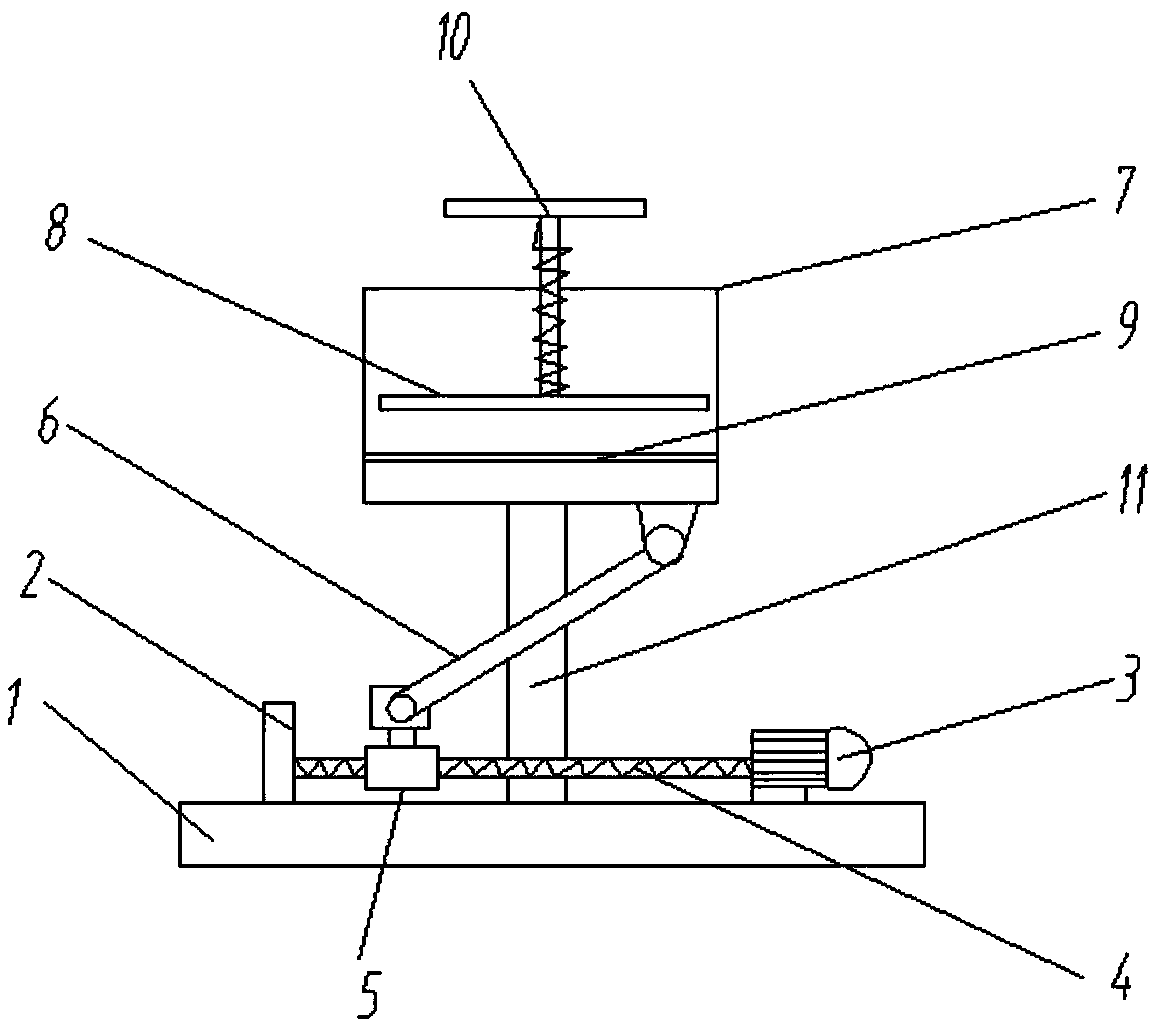

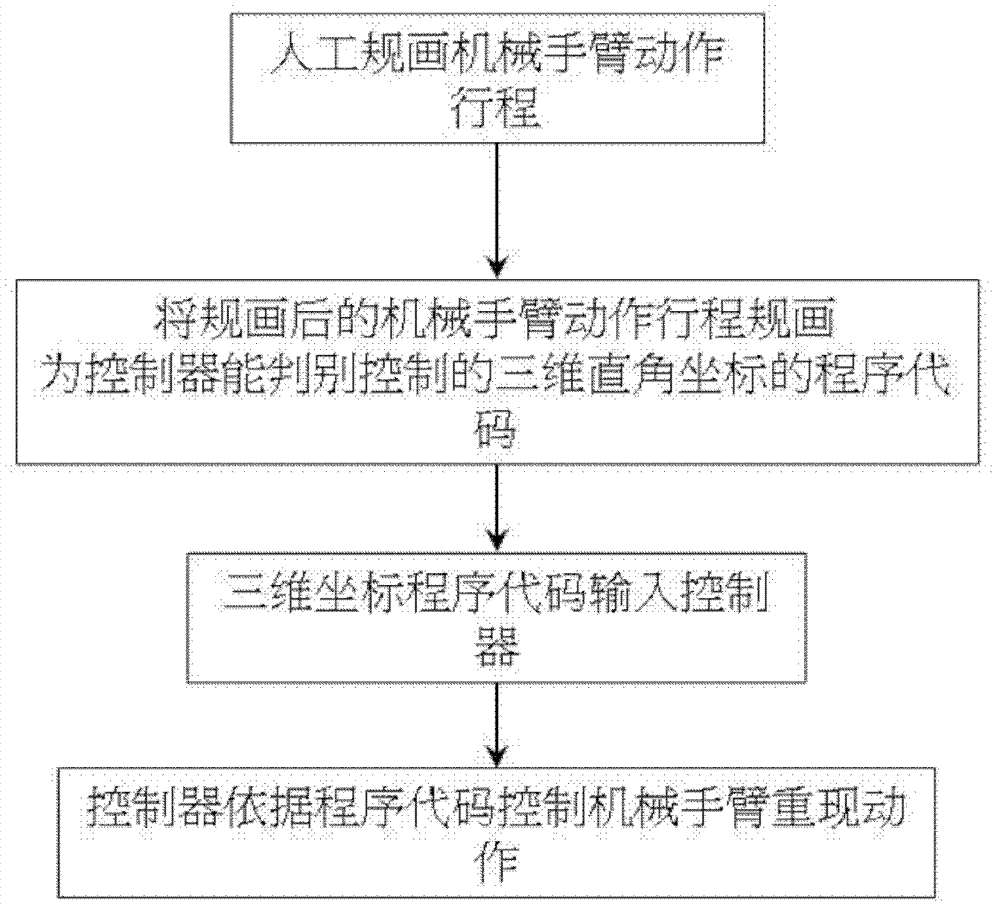

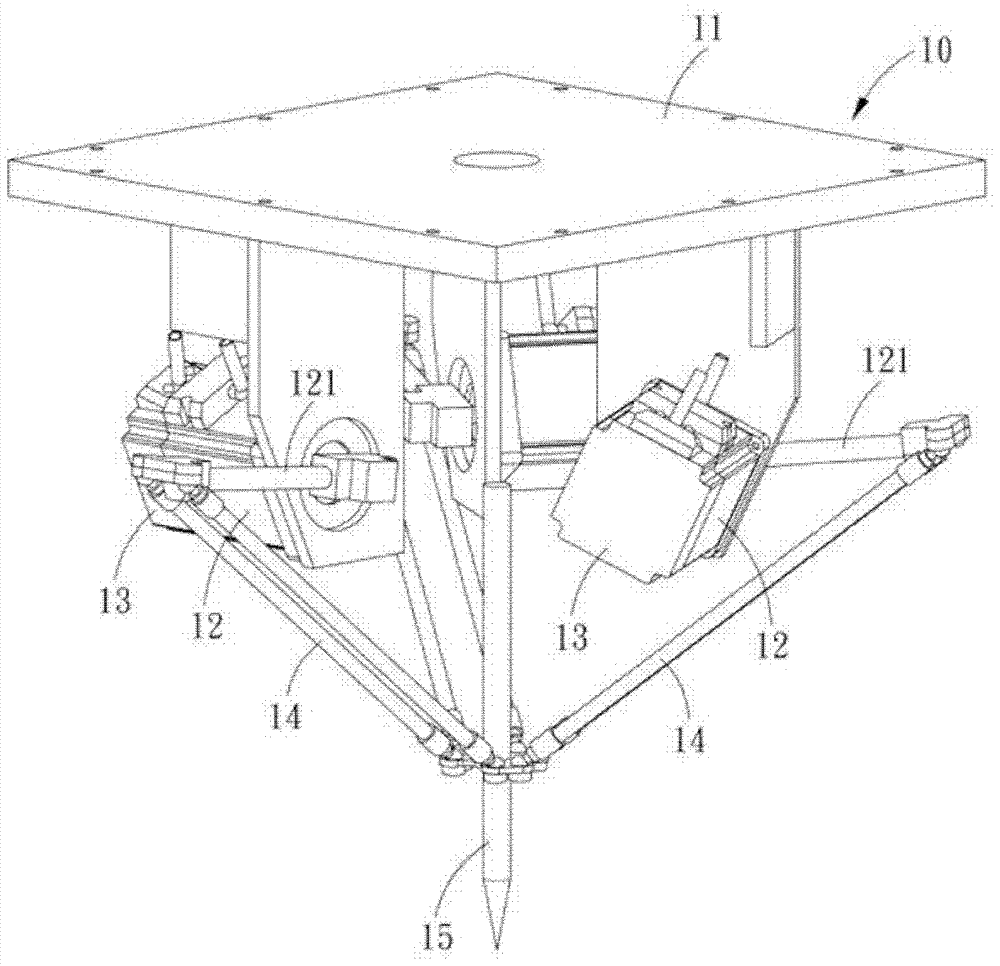

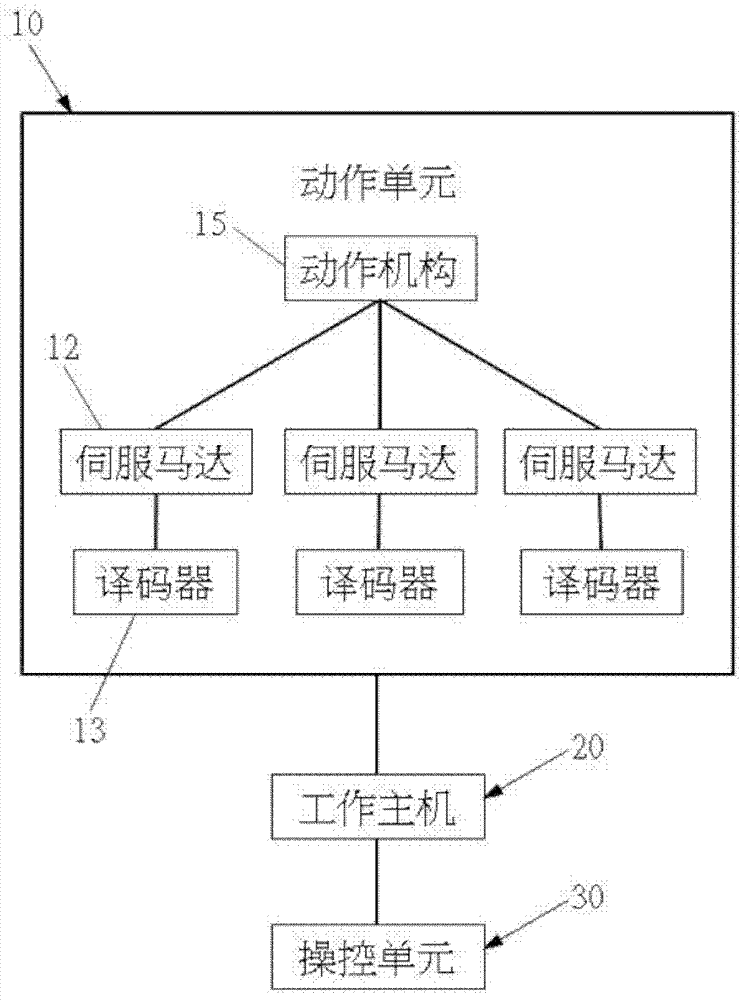

Mechanical arm control action recurrence method

InactiveCN103358307ASolve the defects of low applicabilityProgramme-controlled manipulatorRobotic armImage resolution

The invention provides a mechanical arm control action recurrence method. According to the method, an action mechanism is driven by manual work at the first time to execute actions, and after the actions are executed, a working main machine and a control unit can carry out recording of point locations of the motor actions, transcoding of the point locations, and action recurrence automatically. Due to the automatic process, more accurate and authentic action recording and accurate and authentic action recurrence can be achieved, accurate action recurrence can be achieved without labor which consumes high cost and time, meanwhile, recurrence of fine action details can be achieved only by changing resolution ratios for reading the motor point locations, more detailed actions can be achieved, and applicability in use is improved.

Owner:INTELLIGENCE DEV ENG AID

Telescopic road deceleration strip

The invention discloses a telescopic road deceleration strip in road traffic safe equipment. The road surface is provided with a telescopic deceleration plate and a deceleration strip box. The deceleration strip box is located on the edge of the road. A motor is transversely and horizontally arranged on the edge of the road below the road surface. The output shaft of the motor points to the middleof the road and is coaxially and fixedly connected with one end of the edge of a screw rod transversely and horizontally arranged. The middle end of the other end of the screw rod is located in the middle of the road. The screw rod is coaxially sleeved with a screw rod nut. The screw rod nut is fixedly connected with the lower end of a connecting rod. The upper end of the connecting rod extends upwards out of the road surface and is connected with the telescopic deceleration plate. The motor rotates to drive the connecting rod to move transversely and horizontally. The connecting rod can drive the telescopic deceleration plate to enter the deceleration strip box. The telescopic road deceleration strip is exposed out of an original road surface in a contraction state, so that the smoothness is good when the vehicle passes; the service life of the deceleration strip is prolonged; not only can the effect of alarming of an overspeeded vehicle be ensured, but also can unnecessary vibrationand noise be reduced; and the structure is simple and operation is convenient.

Owner:JIANGSU UNIV

Devices and methods for assessing motor point electromyogram as a biomarker

ActiveUS9820671B2Effectiveness of treatmentWeakening of the diaphragmElectrotherapyElectromyographyActivity indexPhysical therapy

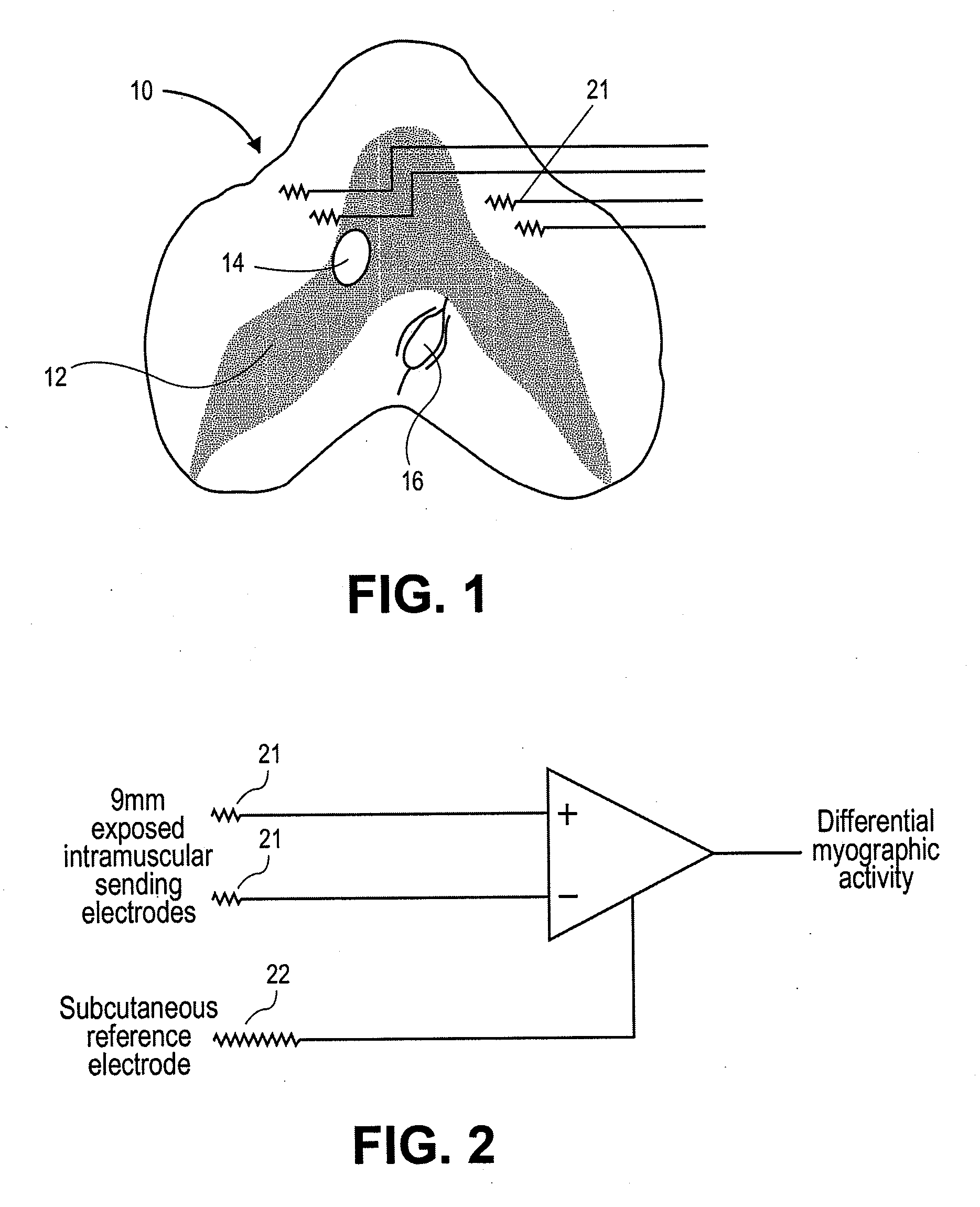

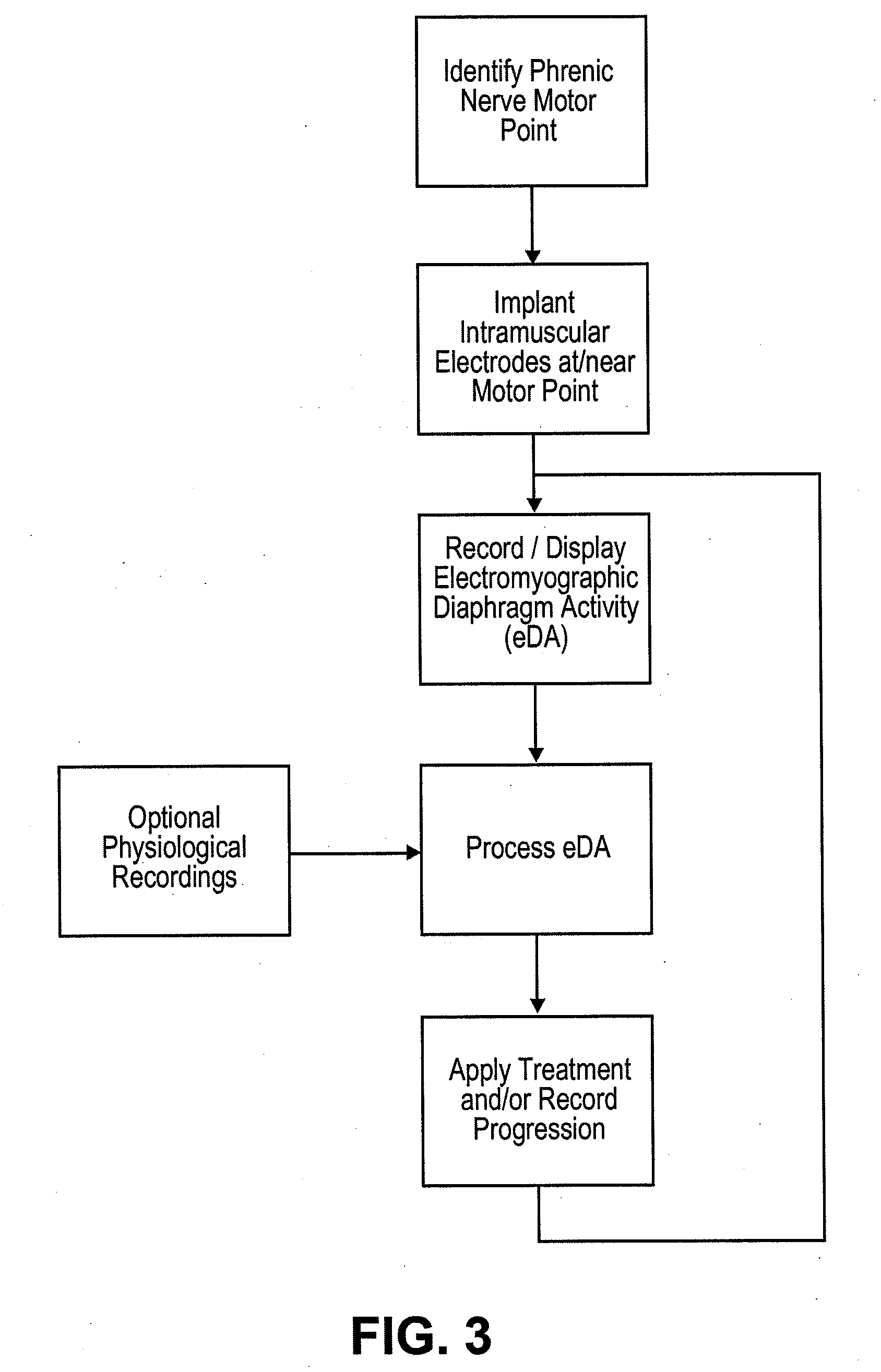

Described herein are methods of detecting the presence or progression of neuromuscular disorders (including ALS) based at least in part on diaphragm EMG signals taken at different points in time from the same implanted electrode(s). Signals may be used to diagnose or to monitor progression of a disorder or to track a treatment. Thus, diaphragm EMG signal may be used as a marker (e.g., a “biomarker”) for the detection or progression of a neurological disorder such as ALS. The characteristics or parameters of diaphragm EMG signals may be used to create an activity index, which may be output or compared and further analyzed. These signals may also be analyzed to show a difference between the left and right sides of the diaphragm.

Owner:SYNAPSE BIOMEDICAL INC

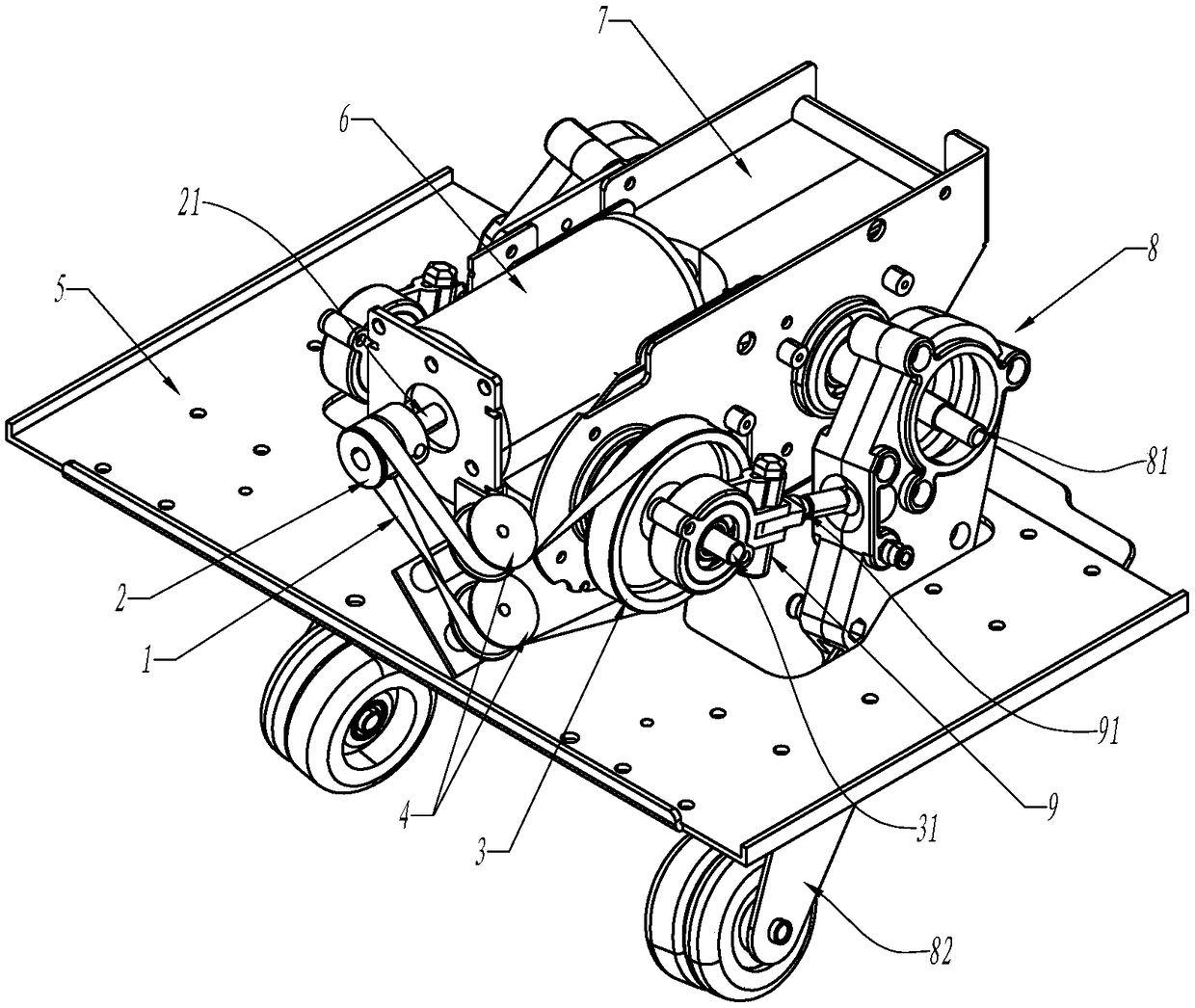

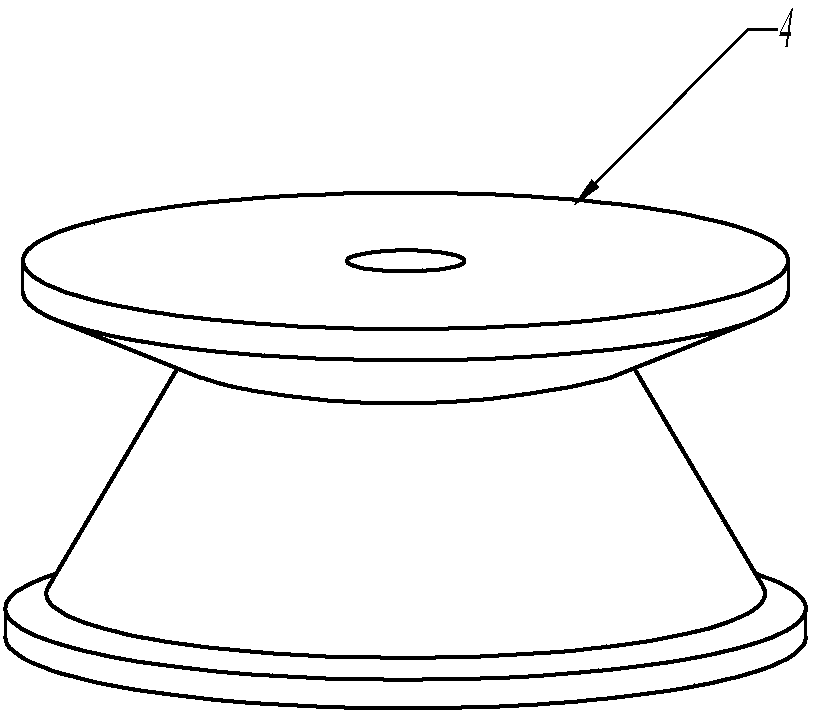

Belt transmission structure and massage manipulator

PendingCN108175657AFew partsSave spaceVibration massageSuction-kneading massageDrive wheelMotor drive

The invention relates to a belt transmission structure and a massage manipulator. The belt transmission structure comprises a driving wheel fixedly locked on a driving shaft, a driven wheel fixedly locked on a driven shaft and a transmission belt; the belt transmission structure further comprises two transition wheels, the two transition wheels are mounted at the tangent plane cross corner of thedriving wheel and the driven wheel, and two tangent lines passing through the transition wheels are correspondingly tangent to the driving wheel and the driven wheel; the transmission belt is sleevedbetween the driving wheel and the driven wheel, and the middle section can bypass the transition wheels to change the direction; the massage manipulator uses the belt transmission structure to transmit the motor power which drives a kneading assembly to a rapping assembly, so that one motor drives both the kneading action and rapping additional action. According to the belt transmission structureand the massage manipulator, the two transition wheels installed between the driving shaft and the driven wheel are cleverly utilized, so that one transmission belt can bypass the two transition wheels to form a turning transmission between the driving wheel and the driven wheel, few parts are arranged by bypassing the motor point location, space is saved, and an option for turning transmission isprovided.

Owner:林学金

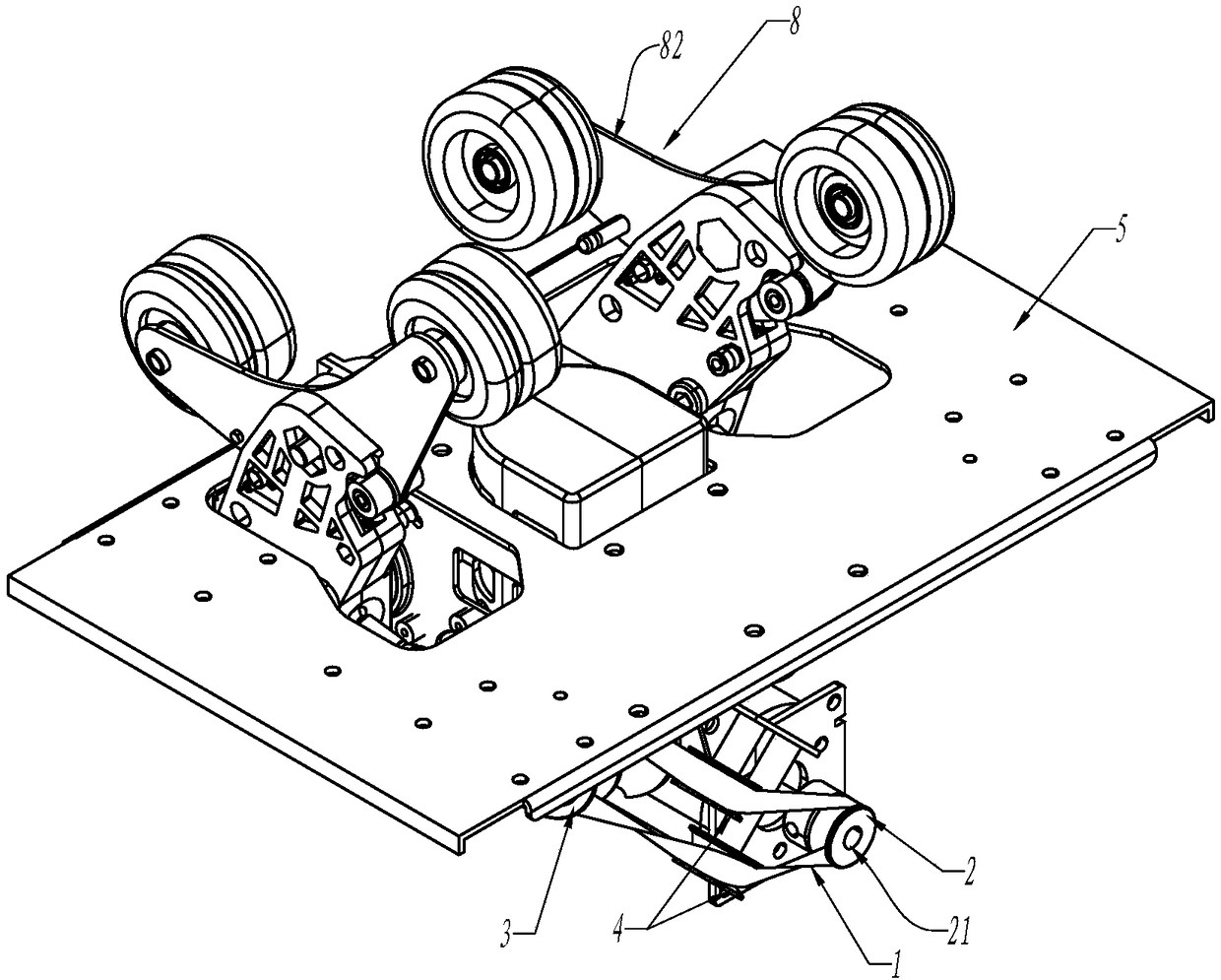

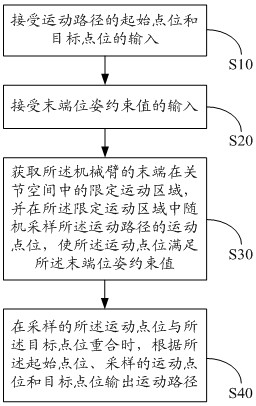

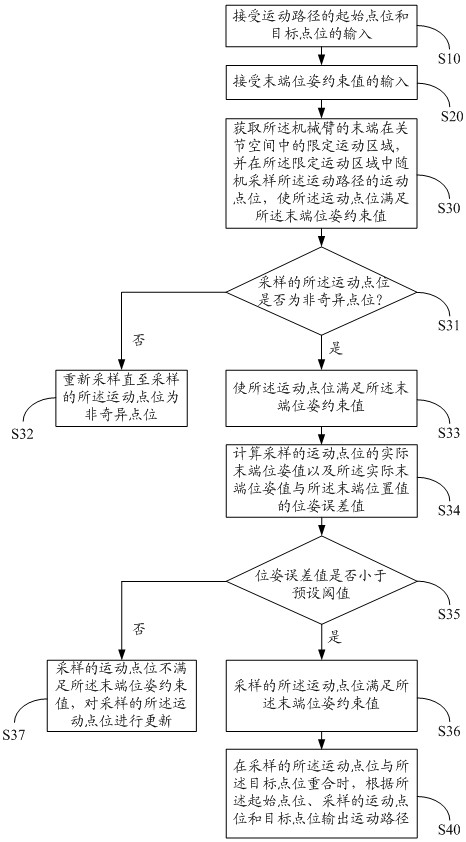

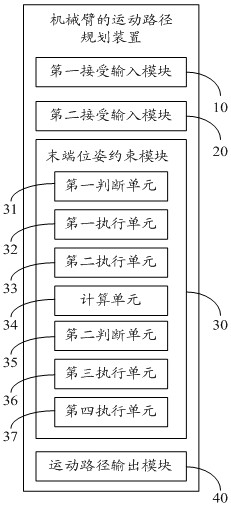

Motion path planning method, device, equipment, medium and robotic arm of robotic arm

The invention discloses a motion path planning method for a mechanical arm. The motion path planning method for a mechanical arm comprises: accepting the input of the starting point and target point of the motion path; accepting the input of the end pose constraint value; obtaining the mechanical The limited motion area of the end of the arm in the joint space, and the motion points of the motion path are randomly sampled in the limited motion area, so that the motion points satisfy the end pose constraint value; When the motion point coincides with the target point, the motion path is output according to the start point, the sampled motion point and the target point. The path points on the motion path planned and generated by the motion path planning method of the mechanical arm of the present invention can meet the given end pose requirements, realize specific operation requirements, and expand application scenarios.

Owner:SHENZHEN YUEJIANG TECH CO LTD

Located therapeutic syringe needle utilizing electricity to stimulate spasm motor point

InactiveCN1827184ASimple production processReduce manufacturing costExternal electrodesInfusion needlesElectricityMuscle spasm

This electric-stimulation spasm point location syringe pinhead contains: metallic pinhead, plastic pin cap, and electric stimulation. Its characteristics are: the outer surface of the metallic pinhead is coated with insulation material Teflor, but the inner surface doses not do insulation treatment; the plastic pin cap is made of innoxious and degradable plastic, and inside the pin cap there is a electric stimulation terminal near metallic pinhead; the electric stimulation terminal is fixed by circling screw in to prevent the terminal from running down, and the terminal is interconnected with electrolyte in pin when injecting, thereby translate the conductance to the metallic pinhead.

Owner:刘志成 +2

Dorsal mode light acoustic imaging method based on multiple phase control focusing ring array

InactiveCN101251514BImprove signal-to-noise ratioImprove imaging resolutionUltrasonic/sonic/infrasonic wave generationOperabilityData treatment

The invention provides a multiple phase control focus ring array-based dorsad mode optical acoustic imaging method; steps of the method are as follows: (1) the pulsed laser is used to irradiate a sample to be tested; (2) the sample to be tested or a multi-ring array detector receives optical acoustic signals by the dorsad mode of a step motor driving scan, and simultaneously acquires the data of optical acoustic signals; (3) data processing software is used to calculate the phase control of the acquired optical acoustic signals for realizing the dynamic focus mode A scan in the depth Z direction, and by the two-dimensional data scanning in the X-Y direction of the step motor point-to-point, a three-dimensional optical absorption distribution map can be synthesized by the back projection. The method has the advantages that due to the adoption of the multi-ring array detector, the super narrow aperture angle and the good direction pointing of the multi-ring array detector greatly improve the imaging resolution, and realize the focus scan imaging in both X and Y directions; due to the adoption of the calculation phase control focus technology, the signal to noise ratio of signals canbe effectively improved, and the mode A dynamic focus scan imaging in the depth Z direction can be realized; due to the receiving of optical acoustic signals in the dorsad mode, the operability and the application range of the system are greatly improved.

Owner:JIANGXI SCI & TECH NORMAL UNIV

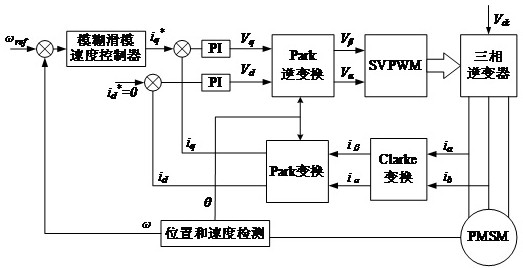

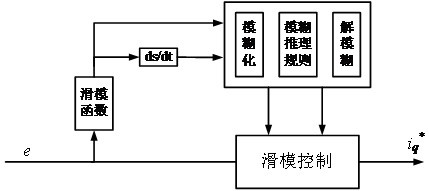

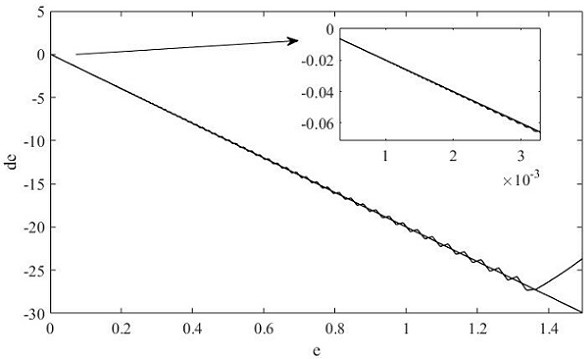

Fuzzy sliding mode control method for permanent magnet synchronous motor based on improved exponential reaching law

ActiveCN112838797BGood speed regulation performanceQuick responseElectronic commutation motor controlAC motor controlMotor speedFuzzy sliding mode control

A fuzzy sliding mode control method for permanent magnet synchronous motors based on an improved exponential reaching law, and a fuzzy sliding mode motor speed control method based on a variable exponential coefficient reaching law, which is the basis of the conventional exponential reaching law in sliding mode control The system state norm is introduced above, so that the speed of the moving point approaching the sliding mode surface in the sliding motion stage and the chattering amplitude in the sliding mode stage are related to the system state variables, so that the approaching speed is associated with the system state change, and combined with fuzzy control to suppress Chattering generated by sliding mode control, the improved control method effectively improves the response speed and accuracy of the system, weakens system chattering, has strong robustness to uncertain disturbances, and greatly improves the performance of the speed control system. performance, so that the motor has better dynamic and static performance.

Owner:SHANDONG UNIV OF SCI & TECH

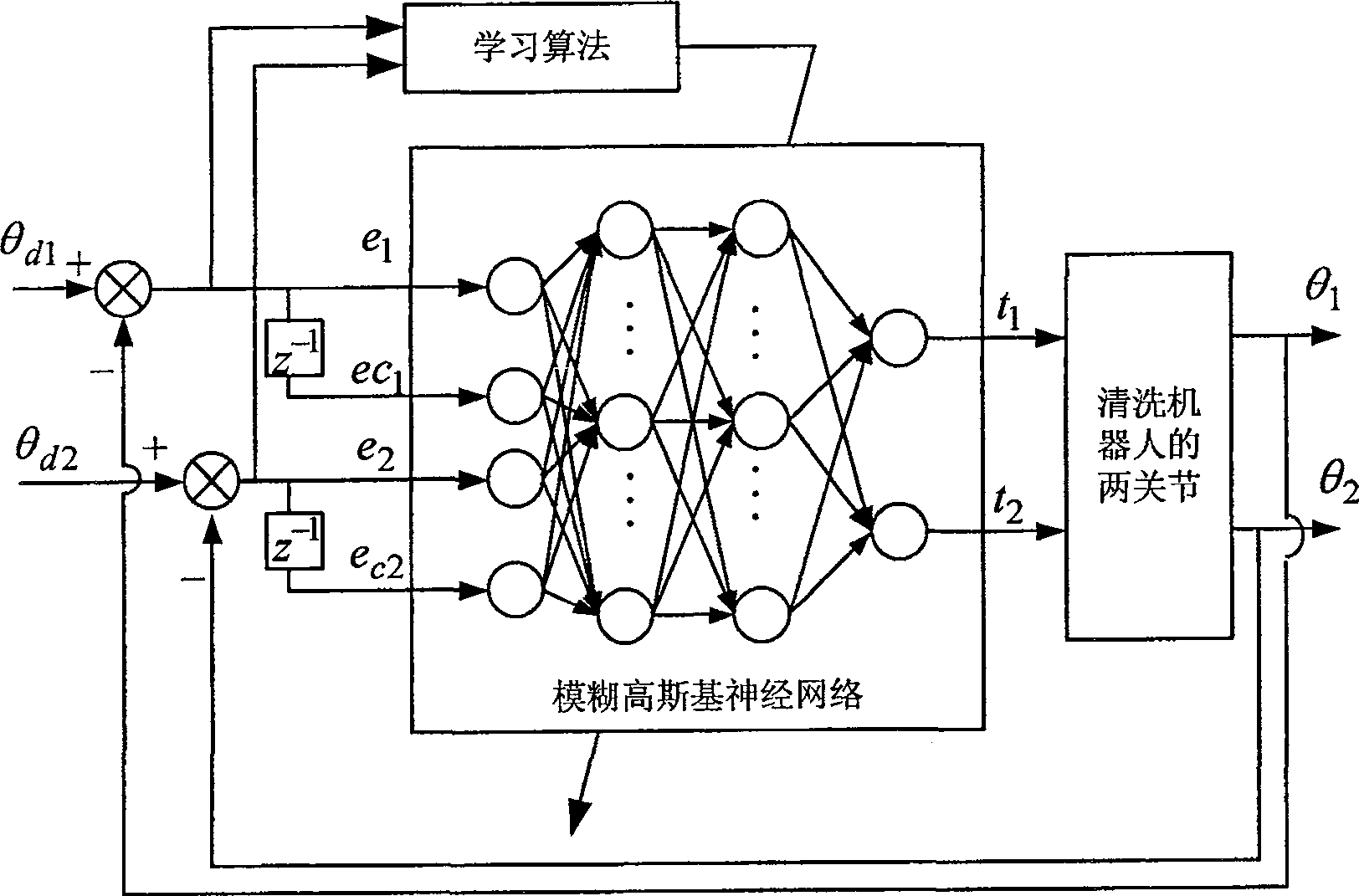

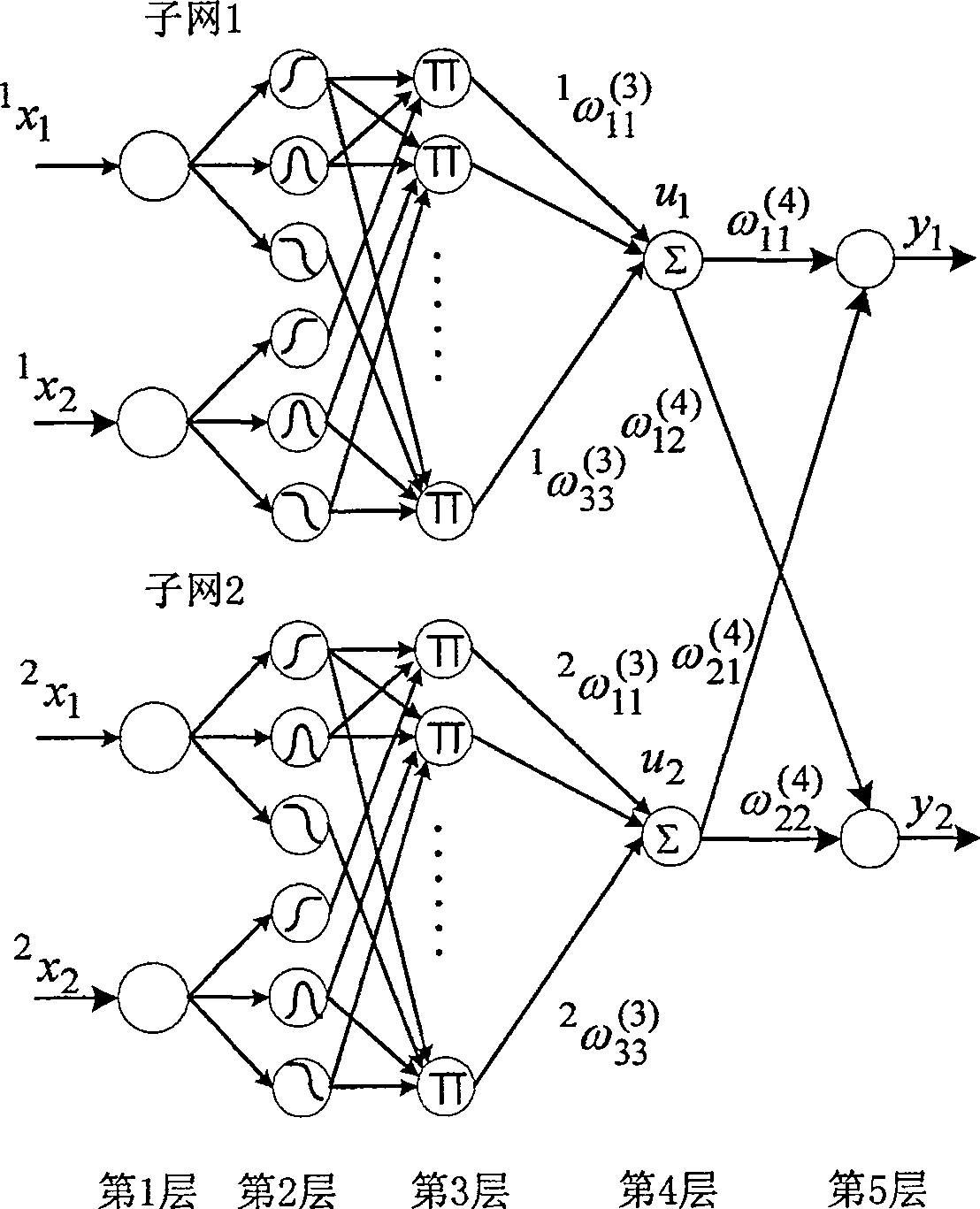

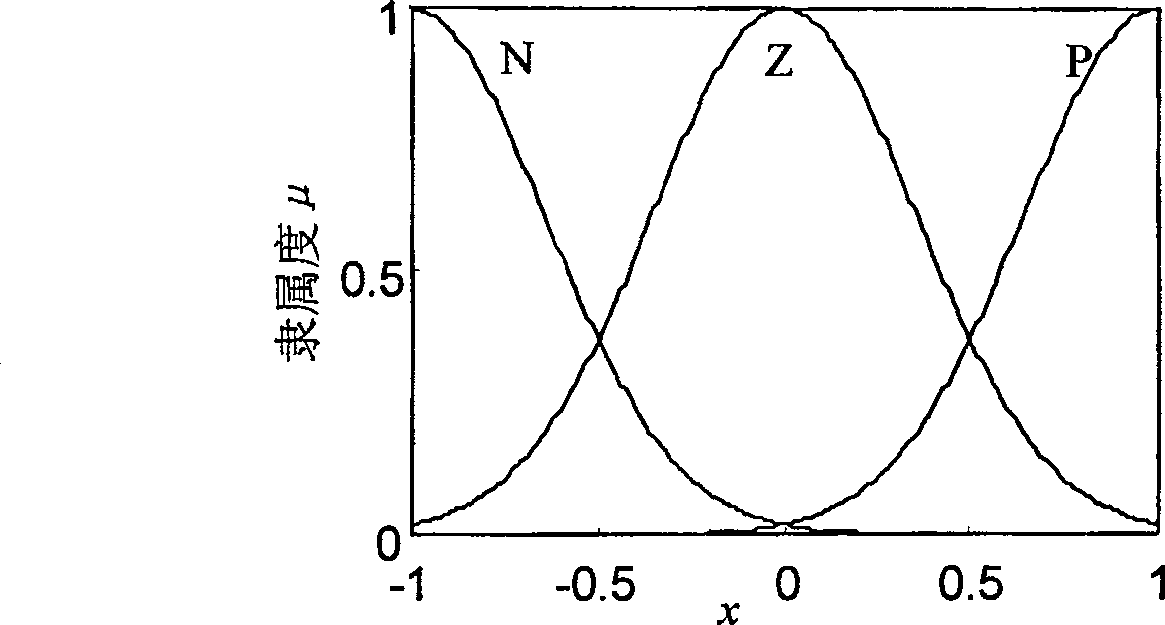

Large condenser underwater operation environment two-joint robot control method

InactiveCN100498600CImprove robustnessSolve control problemsAdaptive controlNeural network controllerControl system

The utility model discloses a control method for controlling a two-joint robot of an underwater-operation condenser. Processes are as following: {1} A controller structure of a fuzzy Kovski neural network is built up and each sub-network represents a serve controller of a joint; {2} Every parameter of the control system and weighted value of network is initialized; an error of an angular displacement of two joints and rate of error is obtained based on the current angular displacement of two joints and expected motion angle displacement; {3}The error and the rate of error are used as the input of the fuzzy Kovski neural network controller and obtain moment exerted on motor points of two joints by fuzzy Kovski neural network controller. Tthe moment is used to control an electric motor, making the joints reach expected elements of a fix. The invention can overcome the difficulty in self-modeling of the robots and uncertainty of environmental disturbance. The utility model can not only sum up experience in controlling of human experts but also have self-study function of neural network controller, thereby reaching a higher controlling degree of accuracy.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com