High-temperature and high-voltage resistant lead for aviation and preparation method thereof

A high-voltage wire and high-temperature-resistant technology, which is applied in the direction of cable/conductor manufacturing, conductors, and conductive materials, can solve the problems of not being able to withstand high temperatures of 400 ° C, and achieve the effect of meeting the requirements of high-temperature and high-voltage resistance and good voltage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

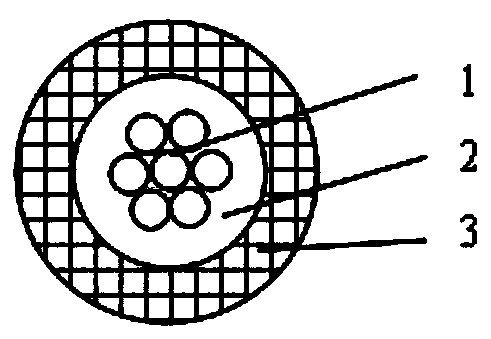

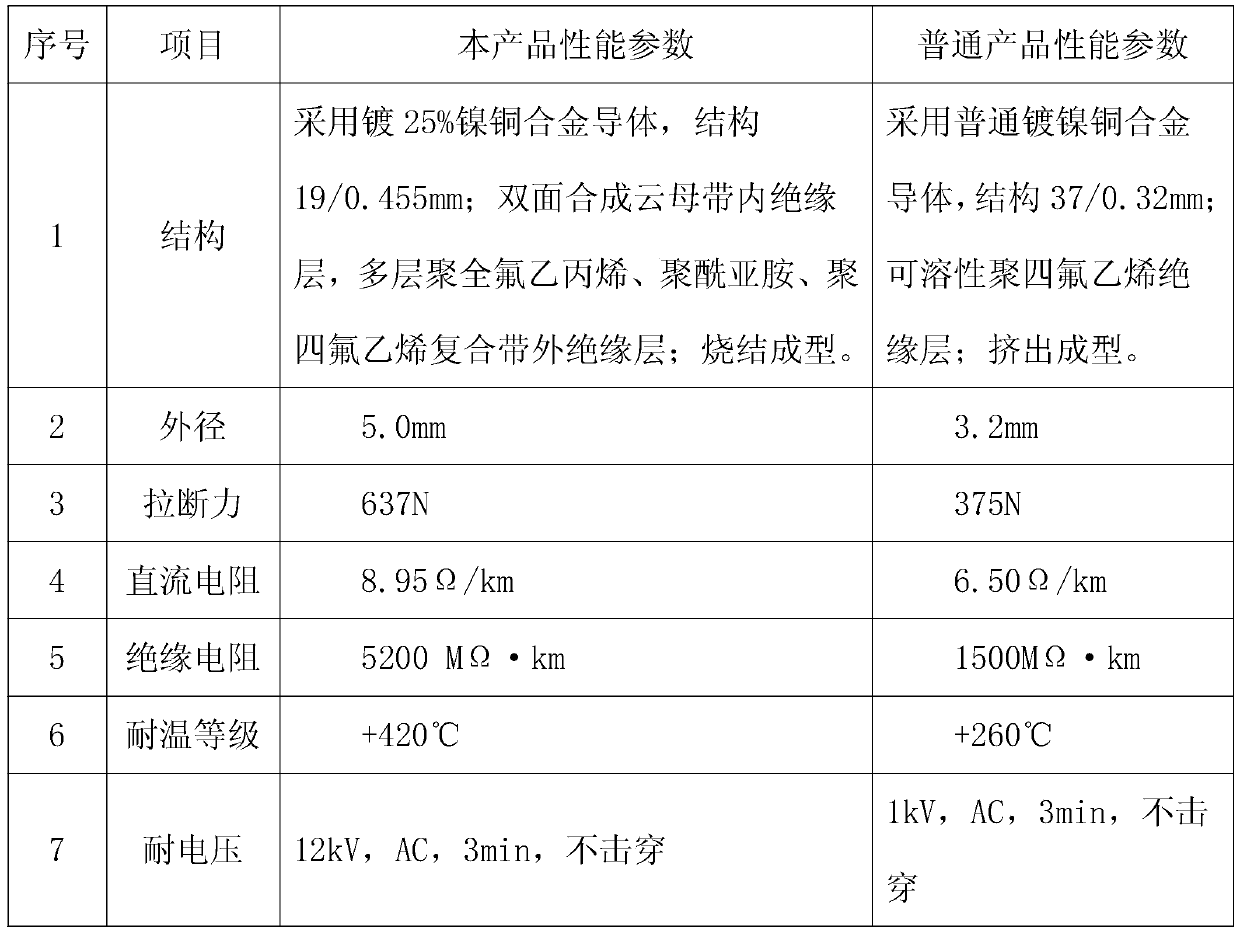

[0032] Example 1, combined with figure 1 , Parameter performance comparison table, process parameter table for description.

[0033] A high temperature and high voltage wire for aviation, refer to the performance parameter comparison table, process table and attached figure 1 The specific instructions are as follows:

[0034] It includes a 25% nickel-copper alloy-plated stranded conductor 1, and the 25% nickel-copper alloy-plated stranded conductor 1 is wrapped with a high-temperature and fire-resistant inner insulating layer 2;

[0035] The inner insulating layer 2 is cross-wrapped with three materials including polyperfluoroethylene propylene, polyimide, and polytetrafluoroethylene as the outer insulating layer 3.

[0036] Further, the inner insulating layer 2 is a double-sided synthetic mica tape with a thickness of 1.0 mm; the outer insulating layer and the inner insulating layer are formed by high-temperature sintering. The mica tape is synthesized from mineral mica, magnesium ...

Embodiment 3

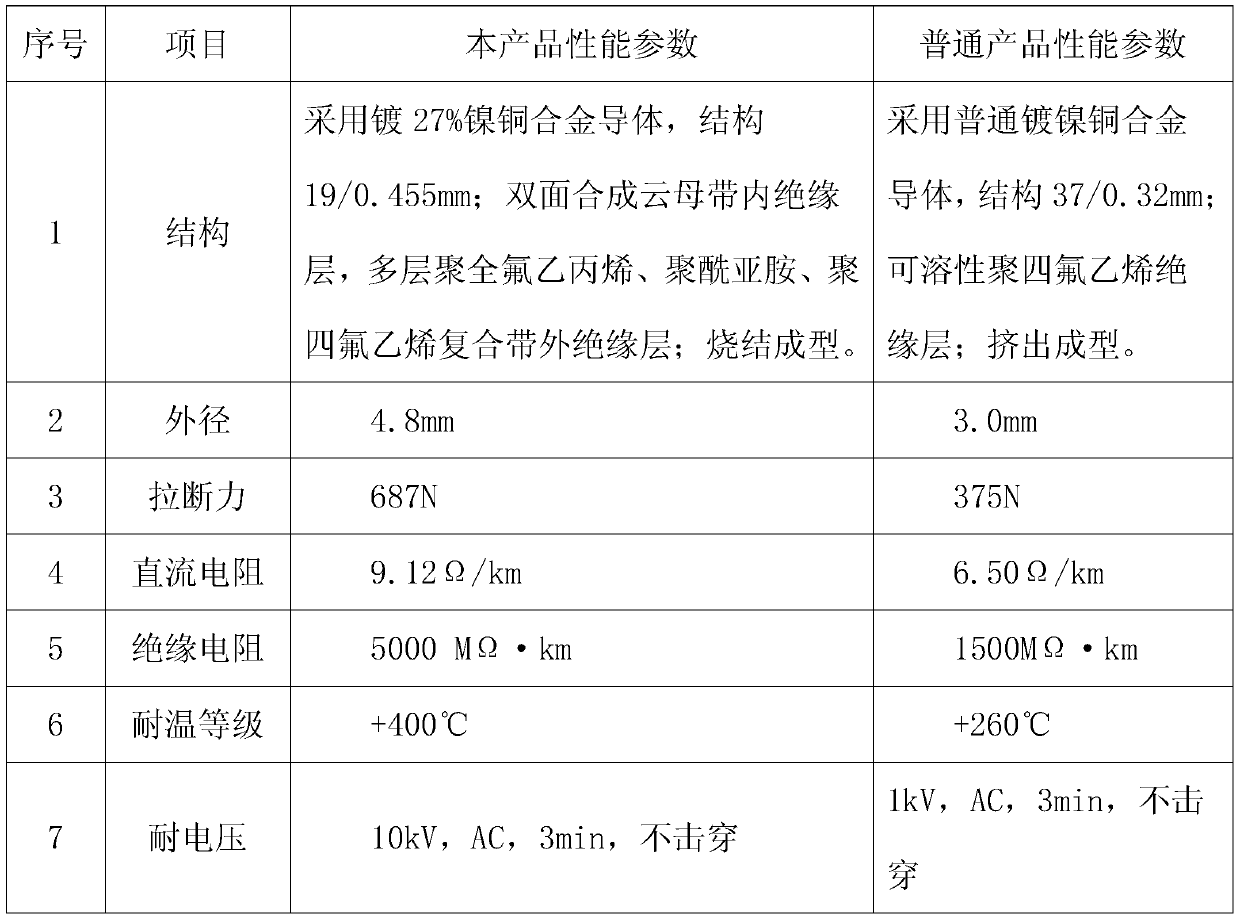

[0074] Example 3, combined with figure 1 , Example 2, parameter performance comparison table, process parameter table are described.

[0075] A high temperature and high voltage wire for aviation, refer to the performance parameter comparison table, process table and attached figure 1 The specific instructions are as follows:

[0076] Including a 32% nickel-copper alloy-plated stranded conductor, the 32% nickel-copper alloy-plated stranded conductor is wrapped with a high-temperature and fire-resistant inner insulating layer;

[0077] The inner insulating layer is cross-wrapped with three materials of polyperfluoroethylene propylene, polyimide, and polytetrafluoroethylene as the outer insulating layer.

[0078] Further, the inner insulating layer is a high-temperature and fire-resistant double-sided synthetic mica tape with a thickness of 1.2 mm; the outer insulating layer and the inner insulating layer are formed by high-temperature sintering.

[0079] Further, the outer insulating l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com