Porous air filtering film as well as preparation method and application thereof

An air filtration and porous substrate technology, applied in the field of composite materials, can solve the problems of decreased adsorption capacity, large porosity, and hazardous waste, and achieve the effects of slowing down the decay rate of charge, improving fiber-forming performance, and increasing storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

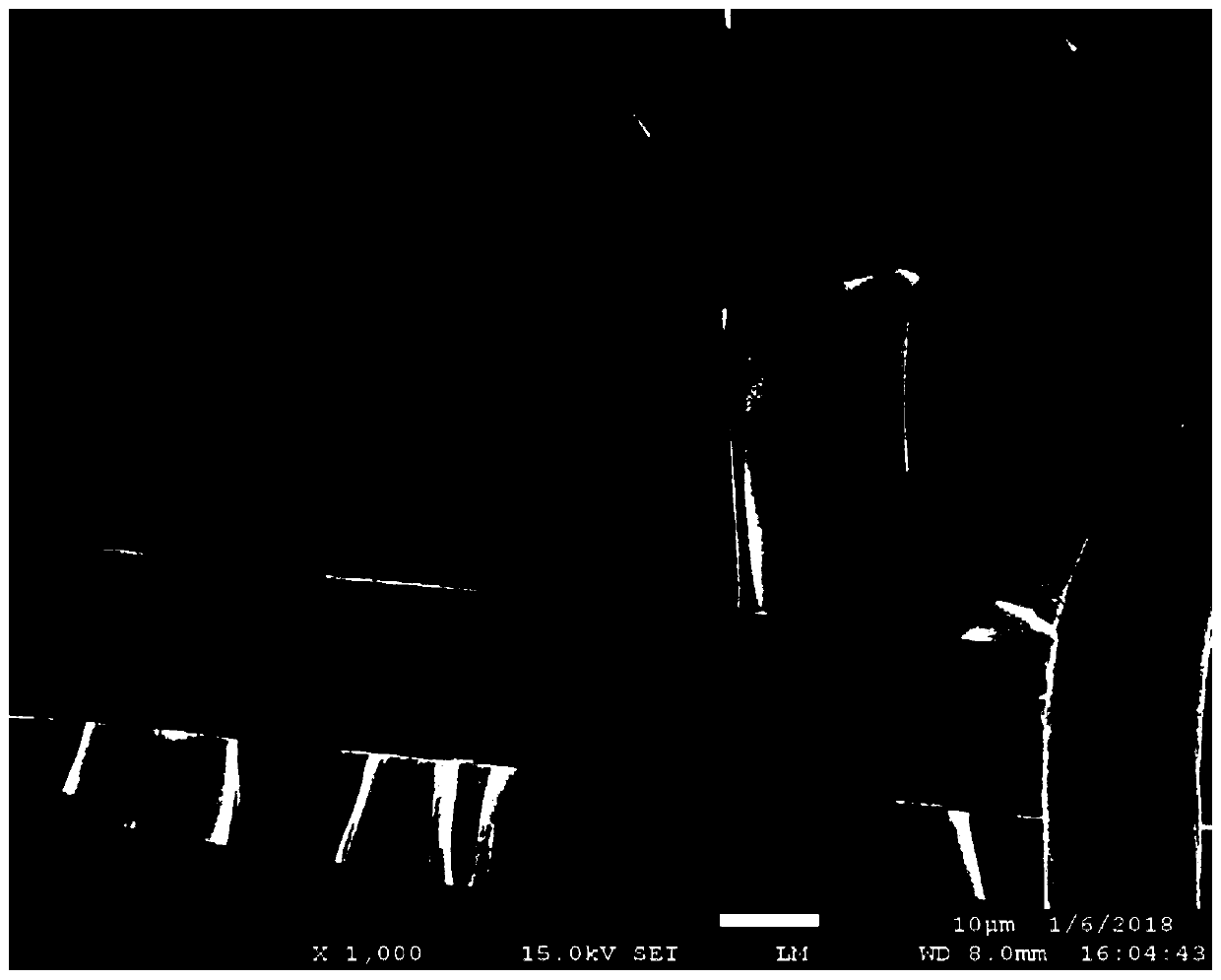

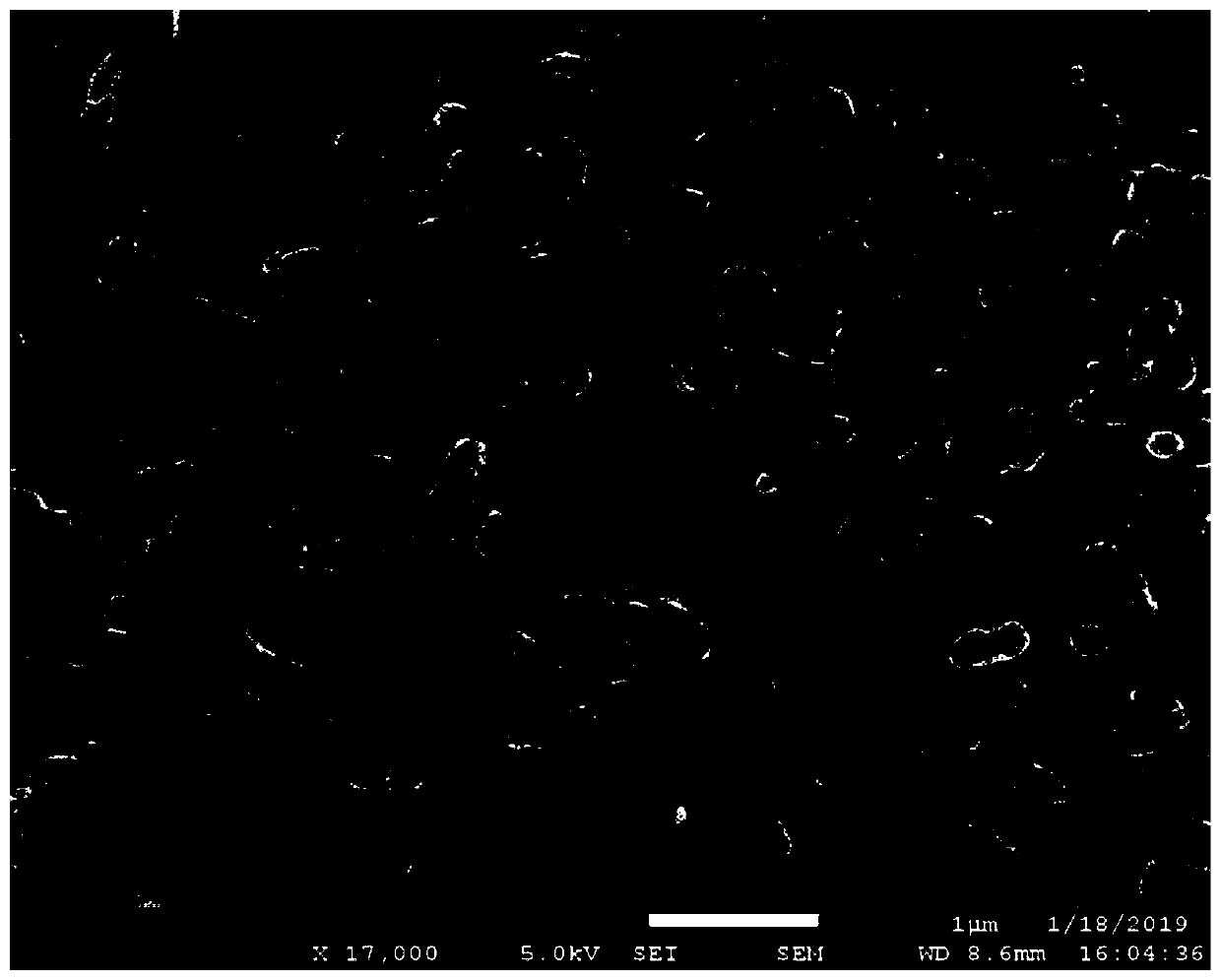

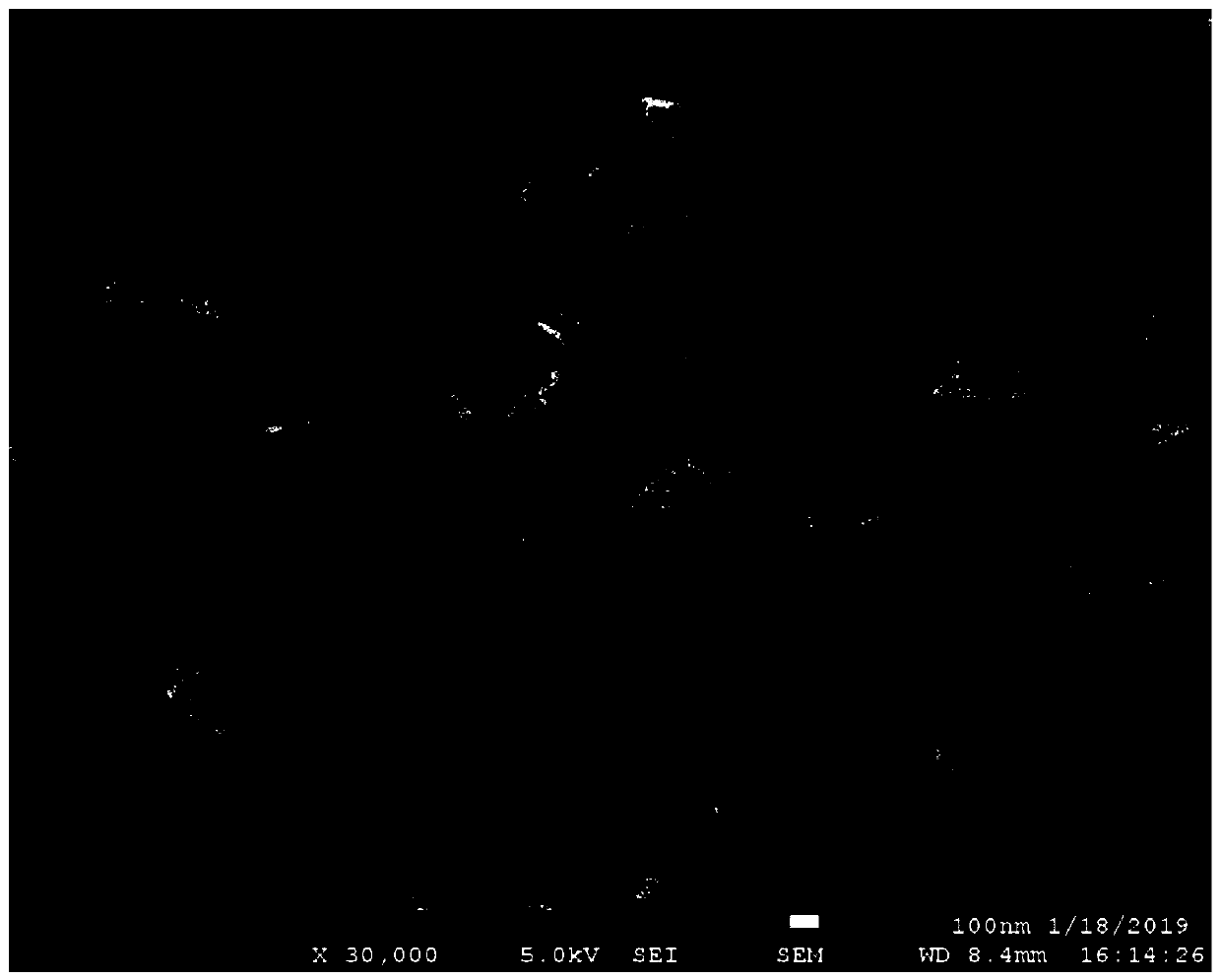

[0073] This embodiment provides a kind of porous air filter membrane, and described porous air filter membrane comprises polypropylene (PP) needle-punched non-woven fabric and the polymer with pyroelectric function covered on the fiber of polypropylene needle-punched non-woven fabric layer, the polymer layer comprising polyvinylidene fluoride (PVDF) and lithium niobate (LN) nanoparticles.

[0074] The preparation method of the present embodiment specifically comprises the following steps:

[0075] (1) Preparation of PVDF solution doped with LN nanoparticles

[0076] Add 0.04g of LN nanoparticles (average particle size is about 200nm) into a stoppered Erlenmeyer flask filled with 98g of DMF solvent, ultrasonically disperse for 0.5h, then add 2g of PVDF powder (weight average molecular weight is 200,000), and stir at 65°C Dissolved uniformly for 3 hours to obtain a uniform solution, ultrasonically dispersed again for 1 hour, and then vacuum defoamed for 10 minutes, wherein the co...

Embodiment 2

[0081] Same as Example 1, the only difference is that the thickness of the polymer layer with pyroelectric function covered on the fibers of the polypropylene needle-punched nonwoven fabric is 0.5 μm.

Embodiment 3

[0083] Same as Example 1, the only difference is that the thickness of the polymer layer with pyroelectric function covered on the fibers of the polypropylene needle-punched nonwoven fabric is 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com