Supported palladium-ultrathin CoNi-LDH (Layered Double Hydroxide) nanosheet composite material as well as preparation method and application thereof

A composite material and supported palladium technology, which is applied in the field of electrocatalysis, can solve the problems of reducing the stability of catalytic active sites, poor stability, and reducing activity, and achieves improved catalytic activity and stability, high stability, and uniform and firm loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

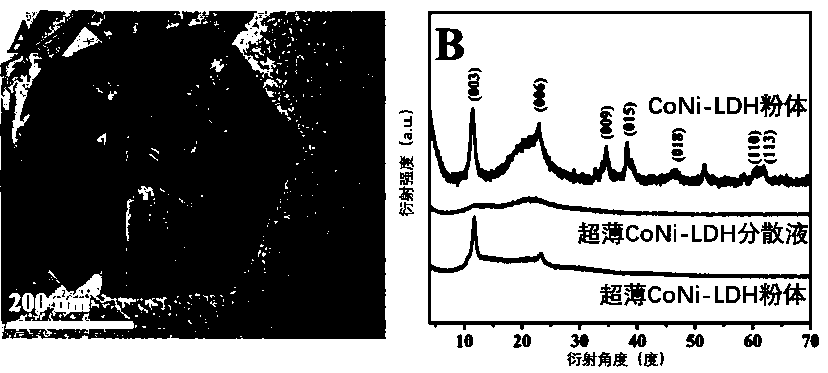

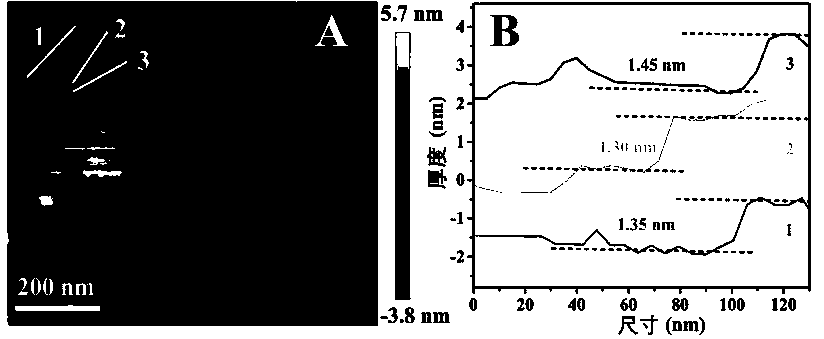

[0023] (1) Preparation of ultrathin CoNi-LDH nanosheets: First, 48 μmol of Ni(NO 3 ) 2 ·6H 2 O, 48 μmol of Co(NO 3 ) 2 ·6H 2 O and 480 μmol of hexamethylenetetramine were ultrasonically dissolved in a mixed solution of 80 mL deionized water and ethanol (ethanol 60 mL, deionized water 20 mL), and then transferred to a 100 mL stainless steel reaction vessel, sealed Placed in a 95 °C oven for 10 h. The obtained product was collected by centrifugation, washed three times with deionized water, and dried at 60°C to obtain ultrathin cobalt-nickel hydrotalcite nanosheets (expressed as CoNi-LDH-UT);

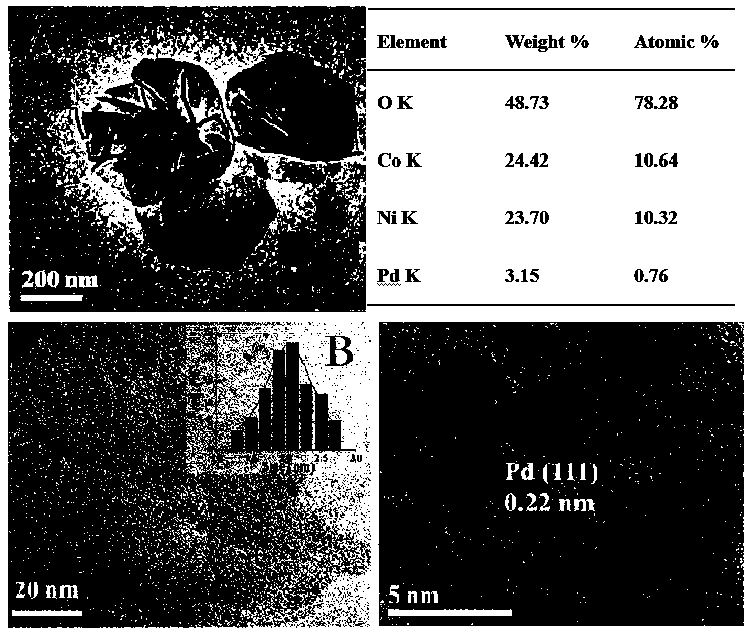

[0024] (2) Preparation of supported PdNPs ultrathin CoNi-LDH nanosheet composites: 1 mg of the prepared CoNi-LDHs-UT was dispersed in 10 mL of aqueous solution, and 1.0 μmol K 2 PdCl 4 (after adding its concentration is 0.1 mmol L -1 ), stirred continuously at room temperature for 6 h, and the obtained product was collected by centrifugation, washed three times with deionized wate...

Embodiment 2

[0030] (1) Preparation of ultrathin CoNi-LDH nanosheets: First, 32 μmol of Ni(NO 3 ) 2 ·6H 2 O, 64 μmol of Co(NO 3 ) 2 ·6H 2 O and 240 μmol of hexamethylenetetramine were ultrasonically dissolved in a mixed solution of 80 mL of deionized water and ethanol (20 mL of ethanol, 60 mL of deionized water), and then transferred to a 100 mL stainless steel reaction vessel, sealed Placed in an oven at 85 °C for 8 h. The obtained product was collected by centrifugation, washed three times with deionized water, and dried at 50°C to obtain ultrathin cobalt-nickel hydrotalcite nanosheets;

[0031] (2) Preparation of supported PdNPs ultrathin CoNi-LDH nanosheet composites: 1 mg of the prepared CoNi-LDHs-UT was dispersed in 10 mL of aqueous solution, and 0.5 μmol K 2 PdCl 4 (after adding its concentration is 0.05 mmol L -1 ), stirred continuously at room temperature for 4 h, and the obtained product was collected by centrifugation, washed three times with deionized water, and dried a...

Embodiment 3

[0033] (1) Preparation of ultrathin CoNi-LDH nanosheets: First, 64 μmol of Ni(NO 3 ) 2 ·6H 2 O, 32 μmol of Co(NO 3 ) 2 ·6H 2 O and 720 μmol of hexamethylenetetramine were ultrasonically dissolved in a mixed solution of 80 mL of deionized water and ethanol (40 mL of ethanol, 40 mL of deionized water), and then transferred to a 100 mL stainless steel reaction vessel, sealed Placed in an oven at 105 °C for 12 h. The obtained product was collected by centrifugation, washed three times with deionized water, and dried at 70°C to obtain ultrathin cobalt-nickel hydrotalcite nanosheets;

[0034] (2) Preparation of supported PdNPs ultrathin CoNi-LDH nanosheet composites: 1 mg of the prepared CoNi-LDHs-UT was dispersed in 10 mL of aqueous solution, and 3.0 μmol K 2 PdCl 4 (after adding its concentration is 0.3 mmol L -1 ), stirred continuously at room temperature for 8 h, and the obtained product was collected by centrifugation, washed three times with deionized water, and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com