C5 desulfurization purification process

A process and desulfurizer technology, applied in the field of C5 desulfurization purification process, can solve the problems of high total sulfur and low purity of C5, achieve quick results, less investment, and increase market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

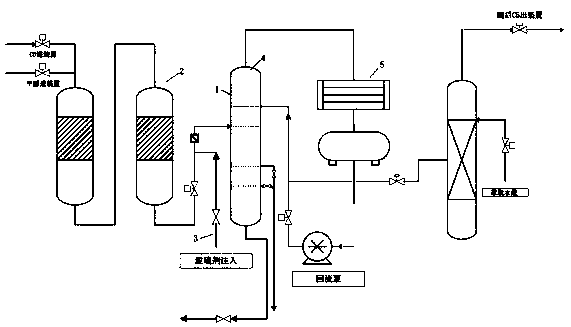

[0014] Such as figure 1 As shown, a C5 desulfurization purification process, a pipeline static mixer 2 is added before the feed of the C5 catalytic distillation tower 1, and a desulfurization agent injection port 3 is added before the pipeline static mixer 2, and the desulfurization agent injection port 3 is connected to a metering pump.

[0015] Further, the middle and upper part of the C5 catalytic distillation tower 1 is provided with a gas phase extraction port 4, through which the methyl tert-amyl ether in the C5 catalytic distillation tower is extracted.

[0016] Further, the reboiler at the bottom of the C5 catalytic distillation tower 1 is connected to a connecting line, so as to continuously discharge the desulfurizer and sulfur reaction product to the sewage treatment device.

[0017] Further, the temperature of the bottom sensitive plate of C5 catalytic distillation tower 1 is controlled at 130°C-138°C; the pressure of the top tower is controlled at 0.26±0.02MPA; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com