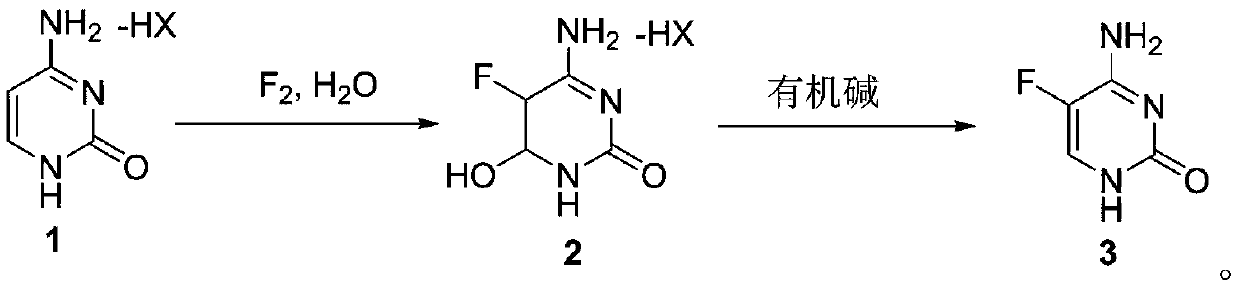

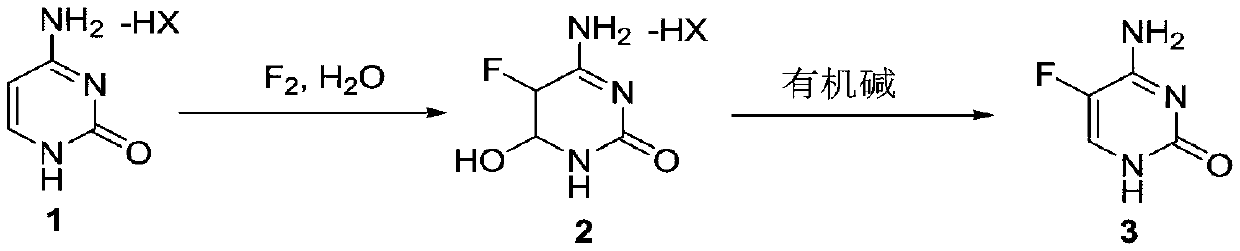

Method for synthesizing 5-flucytosine

A technology for flucytosine and cytosine, which is applied in the field of synthesizing 5-fluorocytosine, can solve the problems of expensive reaction equipment, expensive fluorine reagents and high cost of formic acid, and achieves the advantages of avoiding the use of liquid hydrogen fluoride, reducing the risk factor and reducing the cost of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

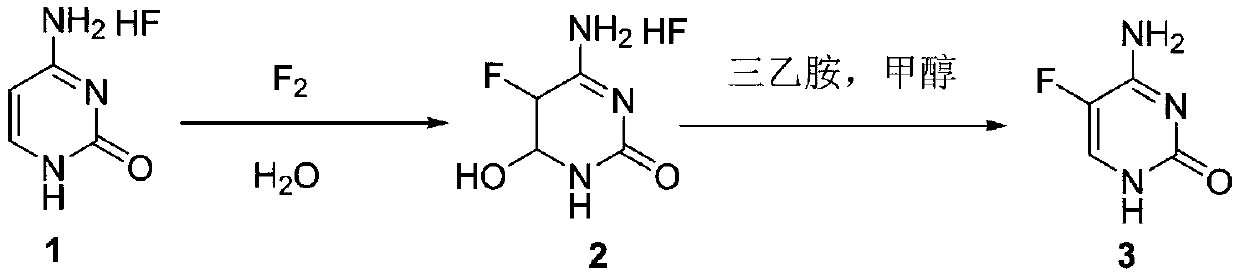

Embodiment 1

[0028]

[0029] In the first step, add 140g (0.30mol) of cytosine hydrogen fluoride and 400mL of water into the reactor, stir evenly, then raise the temperature to 40-45°C and slowly inject 12.5g (0.33mol) of 10% fluorine gas, and follow the reaction in the liquid phase After the raw materials basically disappeared, the temperature was lowered to 0°C to precipitate solids, and the filter cake was suction filtered, washed with a small amount of ice water to obtain intermediate 2, and dried to obtain 45.1 g (0.27 mol) which was put into the next reaction.

[0030] In the second step, add 45.1g (0.27mol) of intermediate 2 into the reactor, then add 300mL of methanol and 41g (0.41mol) of triethylamine, raise the temperature to reflux, then keep the temperature for 5h, and cool down to 10°C after the reaction Left and right, a large amount of solids were precipitated, and the suction filter cake was rinsed with a small amount of methanol to obtain crude 5-fluorocytosine, and then...

Embodiment 2

[0032]

[0033] In the first step, add 140g (0.30mol) of cytosine hydrogen fluoride and 400mL of water into the reactor, stir evenly, then raise the temperature to 40-45°C and slowly inject 12.5g (0.33mol) of 20% fluorine gas, and follow the reaction in the liquid phase After the raw materials basically disappeared, the temperature was lowered to 0°C to precipitate a large amount of solid, which was suction filtered, and the filter cake was washed with a small amount of ice water to obtain Intermediate 2, which was dried to obtain 47g (0.28mol).

[0034] In the second step, in the reactor, add 47g (0.28mol) of intermediate 2, then add 300mL of methanol and 42.4g (0.42mol) of triethylamine, heat up to reflux, then keep the temperature for 5h, and cool down to 10°C after the reaction Left and right, a large amount of solids precipitated, suction filtered, and the filter cake was rinsed with a small amount of methanol to obtain crude 5-fluorocytosine, and then heated to dissolv...

Embodiment 3

[0036]

[0037] In the first step, add 44.1g (0.30mol) of cytosine hydrogen chloride salt and 400mL of water into the reaction kettle. After stirring evenly, raise the temperature to 40-45°C and slowly inject 12.5g (0.33mol) of 20% fluorine gas, and follow the liquid phase After reacting until the raw materials basically disappeared, the temperature was lowered to 0°C to precipitate a large amount of solids, and the filter cake was filtered with suction and rinsed with a small amount of ice water to obtain Intermediate 2, which was dried to obtain 40 g (0.22 mol).

[0038] In the second step, in the reactor, add 40g (0.22mol) of intermediate 2, then add 300mL of methanol and 33.3g (0.33mol) of triethylamine to raise the temperature and reflux for 5h, heat up to reflux, then keep the temperature for 5h, and the reaction is over After cooling down to about 2°C, a large amount of solids precipitated. The filter cake was suction filtered and rinsed with a small amount of methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com