Concrete internal curing agent, preparation method and applications thereof

A concrete internal curing agent technology, which is applied in the field of concrete internal curing agent and preparation, can solve the problems of difficult heat dissipation and poor mechanical properties, and achieve the effects of simple equipment, low production cost, and overcoming uneven heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

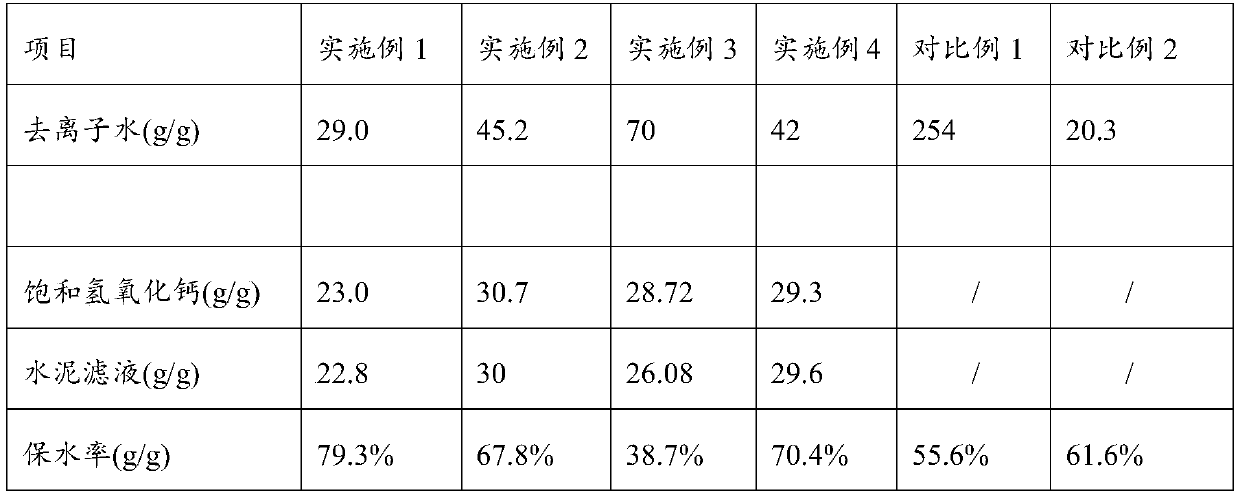

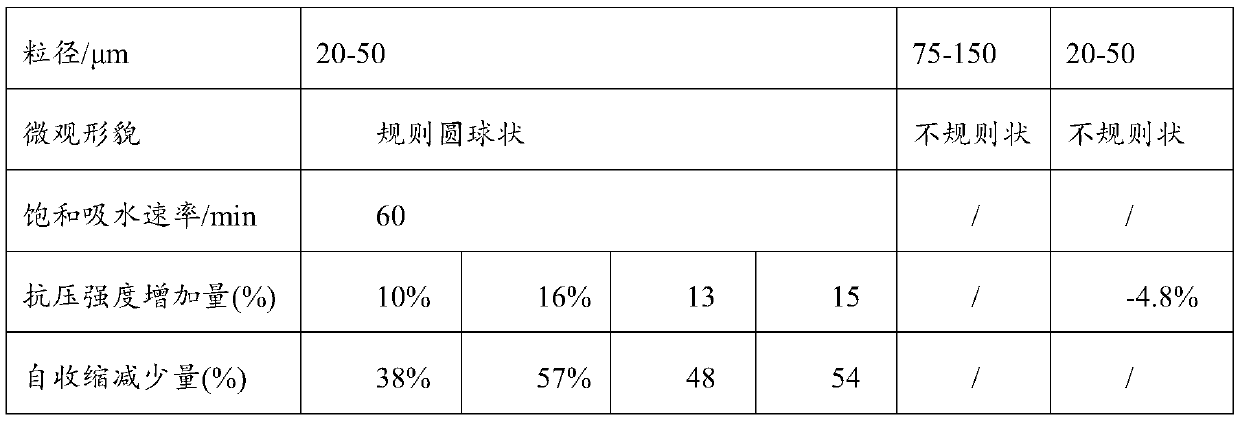

Examples

Embodiment 1

[0045] (1) Weigh 0.5g of sorbitan fatty acid ester and 0.05g of polyoxyethylene sorbitan monooleate, dissolve them in 70mL of n-heptane, stir thoroughly to obtain a mixed solution, and then add it to the three-port In the flask, place it in a water bath at 40°C and stir it thoroughly, and pass N 2 , control the stirring speed at 500rpm, and stir for 40min to fully mix to form an oil phase system;

[0046] Pipette 0.12mL of methacrylic acid (anion: non-ionic mass ratio 1:10) into a glass test tube, and add 0.036g NaOH (neutralization degree is 65%) and 1mL deionized water to it, Shake to dissolve, then add 1.218g N-isopropylacrylamide, 0.06g N,N'-methylene bisacrylamide, 0.1g potassium persulfate, 5mL deionized water to the above mixed solution, and mix thoroughly to prepare water phase system;

[0047] (2) Keep the water bath temperature at 40°C, N 2 Under protection, add the water phase system prepared in step (1) to the oil phase system in step (1), control the rotation s...

Embodiment 2

[0051] (1) Weigh 0.5g of sorbitan fatty acid ester and 0.05g of polyoxyethylene sorbitan monooleate, dissolve them in 70mL of n-heptane, stir thoroughly to obtain a mixed solution, and then add it to the three-port In the flask, place it in a water bath at 30°C and stir it thoroughly, and inject N 2 , control the stirring speed to 500rpm, and stir for 40min to fully mix to form an oil phase system;

[0052] Use a pipette to pipette 0.24mL of acrylic acid (anion: non-ionic mass ratio 1:5) into a glass test tube, and add 0.079gNaOH (neutralization degree is 70%) and 2mL deionized water to it, shake to dissolve, and then Add 1.218g of N-isopropylacrylamide, 0.06g of N,N'-methylenebisacrylamide, 0.1g of potassium persulfate, and 5mL of deionized water to the above mixture, mix thoroughly, and prepare an aqueous phase system;

[0053] (2) Keep the water bath temperature at 40°C, N 2 Under protection, add the water phase system prepared in step (1) into the oil phase system, contr...

Embodiment 3

[0056] (1) Weigh 0.5g of sorbitan fatty acid ester and 0.05g of polyoxyethylene sorbitan monooleate, dissolve them in 75mL of n-heptane, stir thoroughly to obtain a mixed solution, and then add it to the three-port In the flask, place it in a water bath at 30°C and stir it thoroughly, and inject N 2 , control the stirring speed to 500rpm, and stir for 40min to fully mix to form an oil phase system;

[0057] Use a pipette to pipette 0.5 mL of methacrylic acid (anion: non-ionic mass ratio 1:2) into a glass test tube, and add 0.212 g of NaOH (neutralization degree is 75%) and 5 mL of deionized water to it, Shake to dissolve, then add 1.015g N-isopropylacrylamide, 0.06g N,N'-methylene bisacrylamide, 0.1g ammonium persulfate, 5mL deionized water to the above mixture, mix well, and prepare Aqueous system.

[0058] (2) Keep the water bath temperature at 30°C, N 2 Under protection, add the water phase system prepared in step (1) into the oil phase system, control the rotation speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com