Near-ultraviolet excited green phosphor for non-contact temperature detector

A green phosphor, temperature detector technology, used in thermometers, luminescent materials, thermometers with physical/chemical changes, etc., can solve problems such as sensor damage, and achieve the effects of energy saving, high sensitivity, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

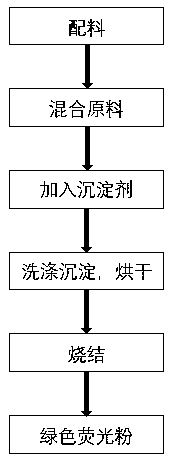

Method used

Image

Examples

Embodiment example 1

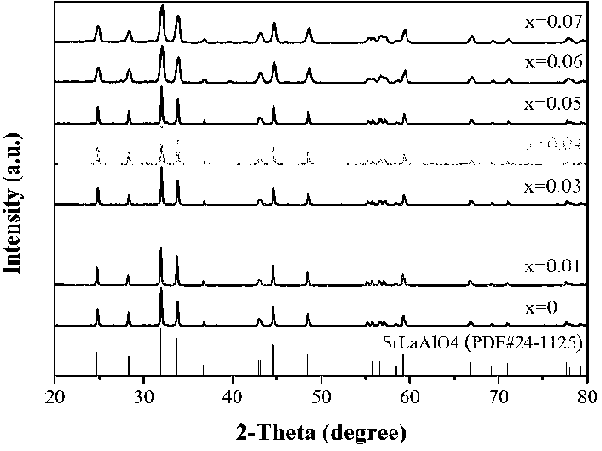

[0019] According to the chemical formula SrLa 0.01 Er 0.99 AlO 4 The stoichiometric ratio of each element in the 3 ) 2 , La(NO 3 ) 3 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Er 2 o 3 , (NH 4 )HCO 3 ; Utilize (NH 4 )HCO 3 Prepare precipitant solution, concentration is 3mol / L; Er that takes by weighing 2 o 3 Dissolve with an appropriate amount of concentrated nitric acid, add a small amount of ultrapure water to configure the erbium nitrate solution; then add the weighed Sr(NO 3 ) 2 (A.R.), La(NO 3 ) 3 · 6H 2 O, Al(NO 3 ) 3 · 9H 2 O was dissolved in ultrapure water, stirred for 30 minutes to fully dissolve, and the prepared erbium nitrate solution was fully mixed with this solution; the precipitant was added dropwise to adjust pH=9 to form a suspension; after 24 hours, remove For the upper liquid, rinse the precipitate with ultrapure water until the nitrate ion disappears; put the precipitate in an oven and dry it thoroughly at 90°C. The dried sample was pulverized...

Embodiment example 2

[0021] According to the chemical formula SrLa 0.03 Er 0.97 AlO 4 The stoichiometric ratio of each element in the 3 ) 2 , La(NO 3 ) 3 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Er 2 o 3 , (NH 4 )HCO 3 ; Utilize (NH 4 )HCO 3 Prepare precipitant solution, concentration is 3mol / L; Er that takes by weighing 2 o 3 Dissolve with an appropriate amount of concentrated nitric acid, add a small amount of ultrapure water to configure the erbium nitrate solution; then add the weighed Sr(NO 3 ) 2 (A.R.), La(NO 3 ) 3 · 6H 2 O, Al(NO 3 )3 · 9H 2 O was dissolved in ultrapure water, stirred for 30 minutes to fully dissolve, and the prepared erbium nitrate solution was fully mixed with this solution; the precipitant was added dropwise to adjust pH=9 to form a suspension; after 24 hours, remove For the upper liquid, wash the precipitate with ultrapure water until the nitrate ion disappears; put the precipitate in an oven and dry it thoroughly at 90°C. The dried sample was pulverized in...

Embodiment example 3

[0023] According to the chemical formula SrLa 0.07 Er 0.93 AlO 4 The stoichiometric ratio of each element in the 3 ) 2 (A.R.), La(NO 3 ) 3 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Er 2 o 3 (99.99%), (NH 4 )HCO 3 ; Utilize (NH 4 )HCO 3 Prepare precipitant solution, concentration is 3mol / L; Er that takes by weighing 2 o 3 Dissolve with an appropriate amount of concentrated nitric acid, add a small amount of ultrapure water to configure the erbium nitrate solution; then weigh the Sr (NO 3 ) 2 (A.R.), La(NO 3 ) 3 · 6H 2 O, Al(NO 3 ) 3 · 9H 2 O was dissolved in ultrapure water, stirred for 30 minutes to fully dissolve, and the prepared erbium nitrate solution was fully mixed with this solution; the precipitant was added dropwise to adjust pH=9 to form a suspension; after 24 hours, remove For the upper liquid, wash the precipitate with ultrapure water until the nitrate ion disappears; put the precipitate in an oven and dry it thoroughly at 90°C. The dried sample was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com