High-quality micro-emulsion cutting fluid for metal machining

A technology of metal processing and microemulsion, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of insufficient cooling of cutting fluid and easy loss of lubricity, and achieve the effect of avoiding the reduction of service life and enhancing the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

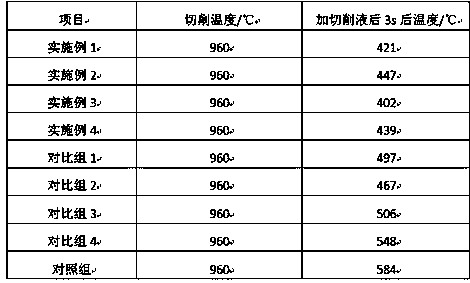

Examples

Embodiment 1

[0020] A high-quality microemulsion cutting fluid for metal processing, comprising the steps of:

[0021] (1) Strong acid oxidation treatment of carbon nanotubes: Weigh 14kg of carbon nanotubes, put them into a strong acid solution weighing 110kg, heat to 90°C, stop heating after 35 minutes of treatment, cool to 25°C by self-heating, take out and use Wash with ionized water until neutral, dry for later use;

[0022] (2) Ball milling of carbon nanotubes: Put the carbon nanotubes obtained in step (1) into a ball mill, mill them for 2.5 hours at a speed of 1200r / min, and then put the carbon nanotubes after ball milling into a 70kg ethylene glycol Alcohol, then add 22kg of nano-MoS 2 , 2.6kg of dimethyl sulfate and 1.4kg of sodium dodecylsulfonate, after stirring evenly, after ultrasonic treatment for 25min for standby, the ultrasonic frequency is 280kHz;

[0023] (3) Preparation of oil-based mixture: Take 26kg of biodegradable base oil, add 7kg of OP-10 NP emulsifier to it and ...

Embodiment 2

[0028] A high-quality microemulsion cutting fluid for metal processing, comprising the steps of:

[0029] (1) Strong acid oxidation treatment of carbon nanotubes: Weigh 12kg of carbon nanotubes, put them into a strong acid solution weighing 100kg, heat to 90°C, stop heating after 30 minutes of treatment, cool to 25°C by self-heating, take out and use Wash with ionized water until neutral, dry for later use;

[0030] (2) Ball milling of carbon nanotubes: Put the carbon nanotubes obtained in step (1) into a ball mill, mill them for 2 hours at a speed of 1200r / min, and then put the carbon nanotubes after ball milling into 70kg of ethylene glycol , then add 24kg of nano-MoS 2 , 2.6kg of dimethyl sulfate and 1.4kg of sodium dodecylsulfonate, after stirring evenly, after ultrasonic treatment for 25min for standby, the ultrasonic frequency is 320kHz;

[0031] (3) Preparation of oil-based mixture: Take 25kg of biodegradable base oil, add 7kg of OP-10 NP emulsifier to it and stir eve...

Embodiment 3

[0036] A high-quality microemulsion cutting fluid for metal processing, comprising the steps of:

[0037] (1) Strong acid oxidation treatment of carbon nanotubes: Weigh 15kg of carbon nanotubes, put them into a strong acid solution weighing 120kg, heat to 90°C, stop heating after 35 minutes of treatment, cool to 25°C by self-heating, take out and use Wash with ionized water until neutral, dry for later use;

[0038] (2) Ball milling carbon nanotubes: Put the carbon nanotubes obtained in step (1) into a ball mill, mill them for 3 hours at a speed of 1200r / min, and then put the carbon nanotubes after ball milling into 80kg of ethylene glycol , and then add 20kg of nano-MoS 2 , 2.5kg of dimethyl sulfate and 1.8kg of sodium dodecylsulfonate, after stirring evenly, after ultrasonic treatment for 25min for standby, the ultrasonic frequency is 240kHz;

[0039] (3) Preparation of oil-based mixture: Take 26kg of biodegradable base oil, add 8kg of OP-10 NP emulsifier to it and stir ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com