Reactive dye printing paste and printing method thereof

A technology of reactive dyes and printing pastes, applied in the field of dyeing and finishing, can solve the problems of printing and dyeing enterprises, excessive ammonia nitrogen content, and increased difficulty in wastewater treatment, and achieve the effect of reducing treatment burden, reducing production costs, and simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

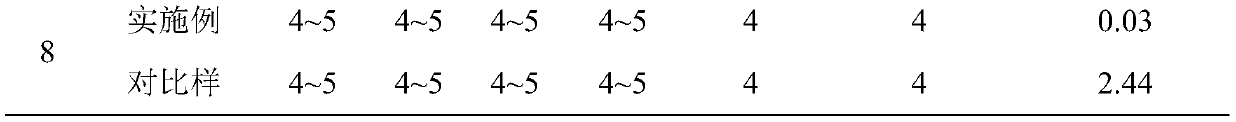

Examples

Embodiment 1

[0030] A reactive dye printing color paste comprises the following components in mass percentage: 10% reactive dye, 30% acrylamide, 0.5% initiator, and the balance is water.

[0031] Utilize the printing method of described reactive dye printing paste, the steps are as follows:

[0032] (1) Preparation method of printing paste: 10% active orange K-R is prepared into a slurry with a small amount of water to obtain solution A, and then 30% urea substitute acrylamide is dissolved with a small amount of water to obtain solution B. At this time, B Add to A, finally add 0.5% initiator potassium persulfate and the rest of water, stir for 120min;

[0033] (2) Printing method of printing color paste: print the printing color paste on the cotton fabric on the printing machine, then dry it at 100°C for 3min, then roll the fabric surface with a solution containing 5% alkali agent sodium bicarbonate, and Steam at 140°C for 10s, then fully wash, soap, wash and dry the printed fabric to obt...

Embodiment 2

[0036] A reactive dye printing color paste, comprising the following components in mass percentage: 0.5% reactive dye, 5% acrylamide, 0.1% initiator, and water as the balance.

[0037] Utilize the printing method of described reactive dye printing paste, the steps are as follows:

[0038] (1) The preparation method of printing paste: 0.5% reactive red M-3BE is modulated into slurry with a small amount of water to obtain solution A, and then 5% urea substitute acrylamide is dissolved with a small amount of water to obtain solution B, at this time Add B to A, and finally add 0.1% initiator ammonium persulfate and the rest of water, and stir for 30 minutes;

[0039](2) Printing method of printing color paste: print the printing color paste on the linen fabric on the printing machine, then dry it at 80°C for 5min, then roll the fabric surface with a solution containing 1% alkali agent sodium hydroxide, and Steam at 130°C for 30s, then fully wash, soap, wash and dry the printed fa...

Embodiment 3

[0042] A reactive dye printing color paste comprises the following components in mass percentage: 3% reactive dye, 30% acrylamide, 0.5% initiator, and the balance is water.

[0043] Utilize the printing method of described reactive dye printing paste, the steps are as follows:

[0044] (1) Preparation method of printing paste: 3% active dark blue KN-5R is prepared into slurry with a small amount of water to obtain solution A, and then 10% urea substitute acrylamide is dissolved with a small amount of water to obtain solution B. Add B to A, finally add 0.5% initiator and the rest of water, and stir for 60 minutes;

[0045] (2) Printing method of printing color paste: print the printing color paste on the ramie fabric on the printing machine, then dry at 60°C for 10min, then roll the fabric surface with a solution containing 3% alkaline agent sodium carbonate, and Steam at 140°C for 20s, then fully wash, soap, wash and dry the printed fabric to obtain printed ramie fabric;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com