Anti-seepage system combining anti-seepage film with salt pond plate and construction method and application thereof

A construction method and technology of salt pool slabs, applied in the field of anti-seepage systems, can solve the problems of geomembrane damage, loss of production resources, safety threats to production personnel and equipment, etc., and achieve the effects of reducing maintenance costs, prolonging life, and not easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

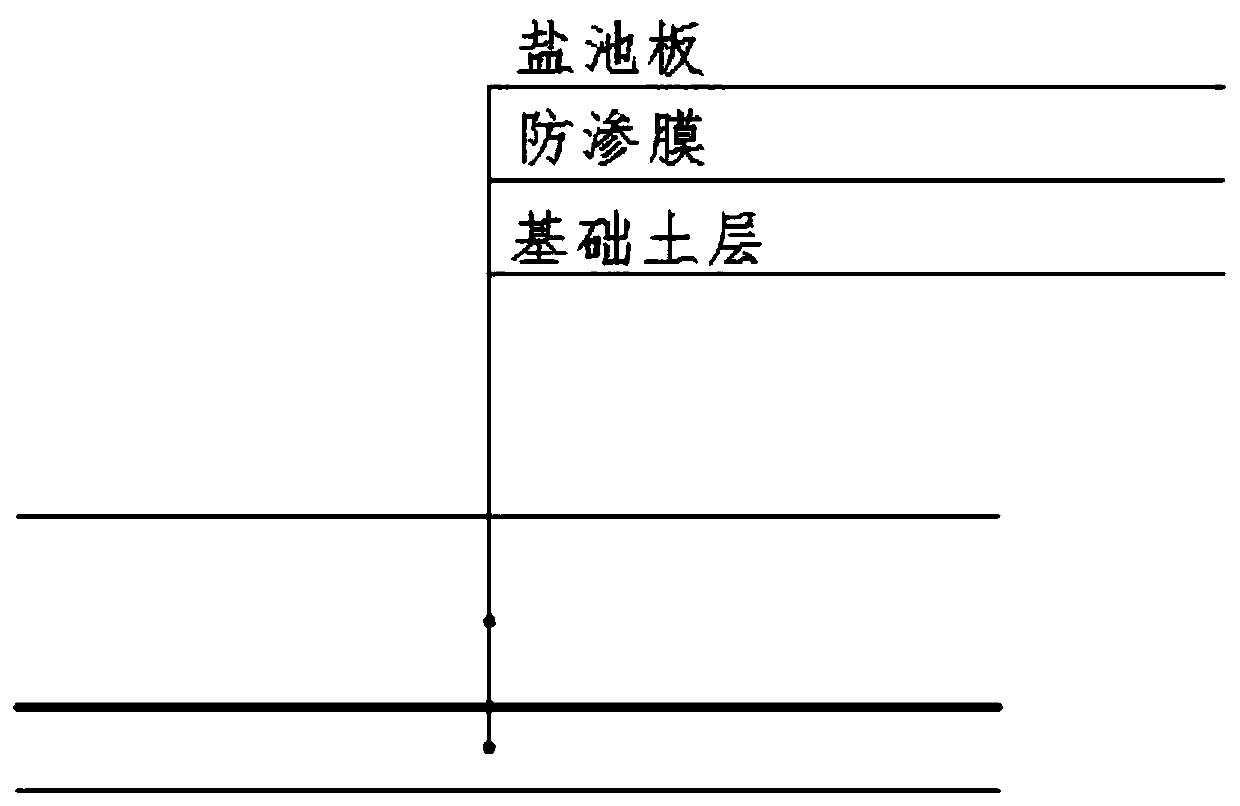

[0038] Such as figure 1 As shown, the present embodiment provides an anti-seepage system combining a geomembrane and a salt pool plate, including a base soil layer, a geomembrane and a salt pool plate, wherein the thickness of the base soil layer is 30 cm, the number of geomembrane layers is 1, and the thickness is 1.5 cm. mm.

[0039] The construction method is as follows:

[0040] (1) Clean, level, and mechanically compact the soil layer at the bottom of the beach drying pond. If the soil layer is too dry, some fresh water can be sprayed to increase the water content to facilitate rolling. The obtained foundation soil layer has a thickness of 30cm and a compressive strength ≥1.5kgf / cm 2 , dry bulk density ≥ 1.6g / cm3 .

[0041] (2) Lay geomembrane on the foundation soil layer and pass the inspection.

[0042] (3) Pour new brine into the beach drying pool where the geomembrane is laid, and the crystalline salt is sodium chloride. In the process of sodium chloride crystall...

Embodiment 2

[0046] Others are the same as in Example 1, the only difference is that the thickness of the base soil layer is 35cm, the number of geomembrane layers is 2 layers, the thickness of the single-layer geomembrane is 1mm, and the thickness of the salt pool plate is 40cm, and the construction method is the same as in Example 1 .

[0047] After testing, the compressive strength of the anti-seepage system can reach 2.5kgf / cm 2 Above, the service life can reach more than 10 years, and the geomembrane will not be damaged during use.

Embodiment 3

[0049] Others are the same as in Example 1, the only difference being that the thickness of the base soil layer is 20cm, the number of geomembrane layers is 1 layer, the thickness of a single-layer geomembrane is 0.35mm, and the thickness of the salt pool plate is 20cm. Construction method and embodiment 1 same.

[0050] After testing, the compressive strength of the anti-seepage system can reach 1.5kgf / cm 2 Above, the service life can reach more than 10 years, and the geomembrane will not be damaged during use.

[0051] It can be seen from the above examples that the anti-seepage system provided by the present invention is a double anti-seepage system of geomembrane and salt pool plate, which combines the short-term anti-seepage of geomembrane with the long-term anti-seepage and compressive strength of salt pool plate to realize The technical effect of meeting the compressive strength requirements of mechanically collected ore while preventing seepage; and the construction m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com