A kind of synthesis of flame retardant microcapsule and preparation method of flame retardant fabric

A synthesis method and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, flame-retardant fiber, etc., can solve the problems of microcapsule preparation difficulty and industrialization difficulty, and achieve low preparation cost, convenient use, and washable performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Sample type: pure cotton fabric

[0040] (1) Soak the cotton fabric in deionized water for 30 minutes, and set it aside, at this time, the surface of the cotton fabric is negatively charged.

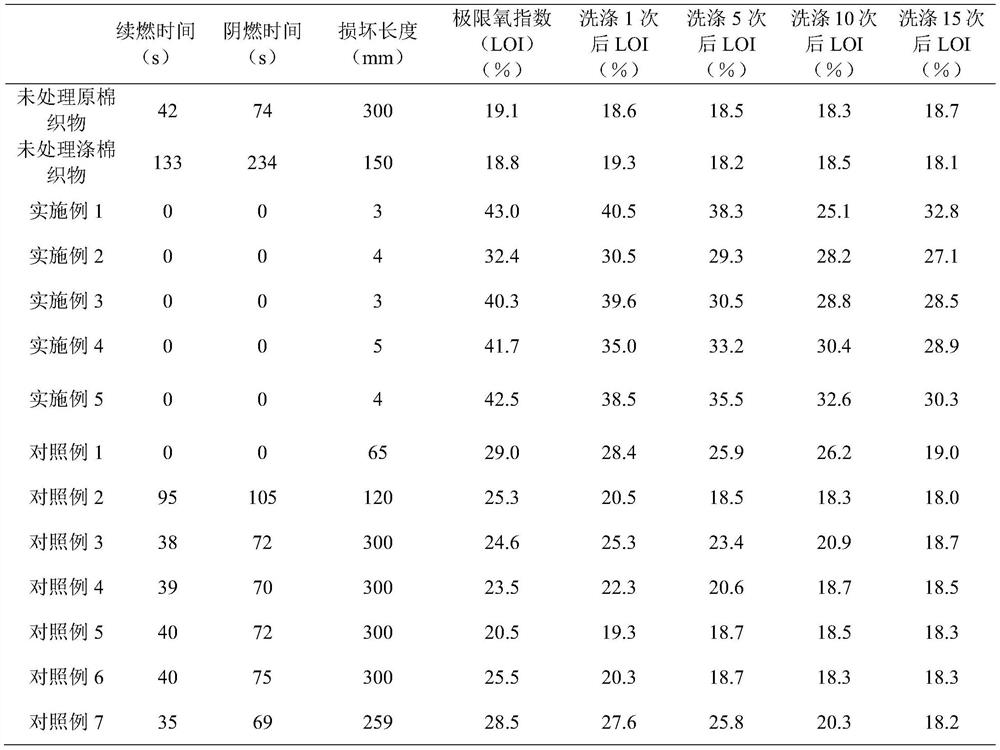

[0041] (2) Prepare the microcapsules whose outermost layer is a chitosan solution and whose surface is positively charged. The properties of the treated fabric are shown in Table 1.

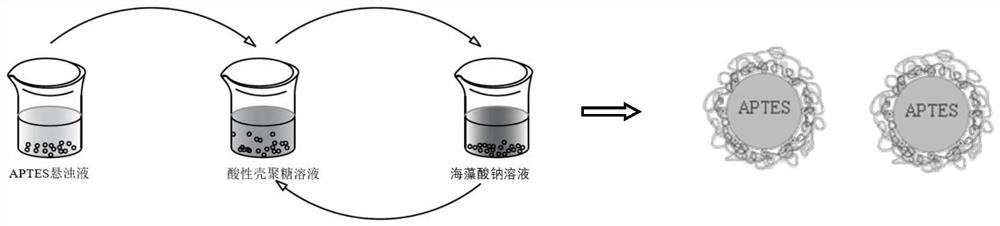

[0042] Concrete steps: prepare 3-aminopropyltriethoxysilane APTES suspension with a concentration of 5g / L, add acidic chitosan solution with a concentration of 5g / L, 3-aminopropyltriethoxysilane APTES suspension The mass ratio of turbid liquid and acidic chitosan is 1:25, mixed reaction, centrifugation, centrifugation speed is 12000rpm, centrifugation time is 10min, the precipitation after centrifugation is dissolved in the deionized water that is 1:30 with the mass ratio of precipitation, 50 crushing treatments were performed in an ultrasonic cell pulverizer (parameters for each treatment: ultraso...

Embodiment 2

[0045] Sample species: polyester-cotton blended fabric (blend ratio: 80 / 20)

[0046] (1) Soak the polyester fabric in 1M NaOH solution, and keep it at 70°C for 30 minutes to partially hydrolyze the surface of the polyester fiber so that it is easier to absorb the electrolyte.

[0047] (2) Prepare microcapsules whose outermost layer is sodium alginate and whose surface is negatively charged.

[0048] Specific steps: APTES suspension with a concentration of 10g / L is prepared, acid chitosan solution with a concentration of 3g / L is added, mixed reaction, 3-aminopropyltriethoxysilane APTES suspension and acid chitosan The mass ratio is 1:30, centrifuged, the centrifugal speed is 10000rpm, and the centrifugation time is 15min. The precipitate after centrifugation is dissolved in deionized water with a mass ratio of 1:40 to the precipitate, and crushed in an ultrasonic cell pulverizer for 45 times , (parameters for each treatment: ultrasonic treatment 8s, intermittent 5s, power 600W...

Embodiment 3

[0051] The core flame retardant in Example 1 was replaced by polydimethylsiloxane, the wall materials were chitosan and sodium lignosulfonate, and other parameters remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com