Pavement crack pouring material and preparation method and application thereof

A technology for filling seam materials and raw materials, which is applied in building thermal insulation materials, building components, buildings, etc., can solve problems such as reducing bearing capacity, accelerating surface bending damage, reducing pavement performance, and improving thermal expansion and contraction deformation. Strong environmental adaptability and good interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the pavement joint filling material described in the above technical solution, comprising the following steps:

[0042] a) mixing the foaming agent with water to obtain a raw material mixture;

[0043] b) After heating the asphalt, spray the raw material mixture obtained in step a) into the heated asphalt by using asphalt foaming equipment to obtain foamed asphalt;

[0044] c) mixing the foamed asphalt obtained in step b) with fibers and fillers to obtain a pavement joint filling material.

[0045] In the present invention, the foaming agent is first mixed with water to obtain a raw material mixture. In the present invention, the foaming agent and water are the same as those described in the above technical solution, and will not be repeated here. The present invention has no special limitation on the mixing method, and the technical scheme of manual stirring or mechanical stirring well known to those skilled...

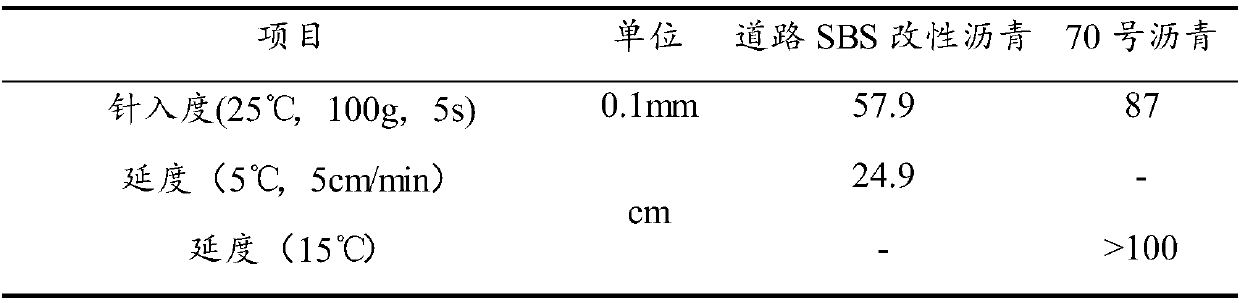

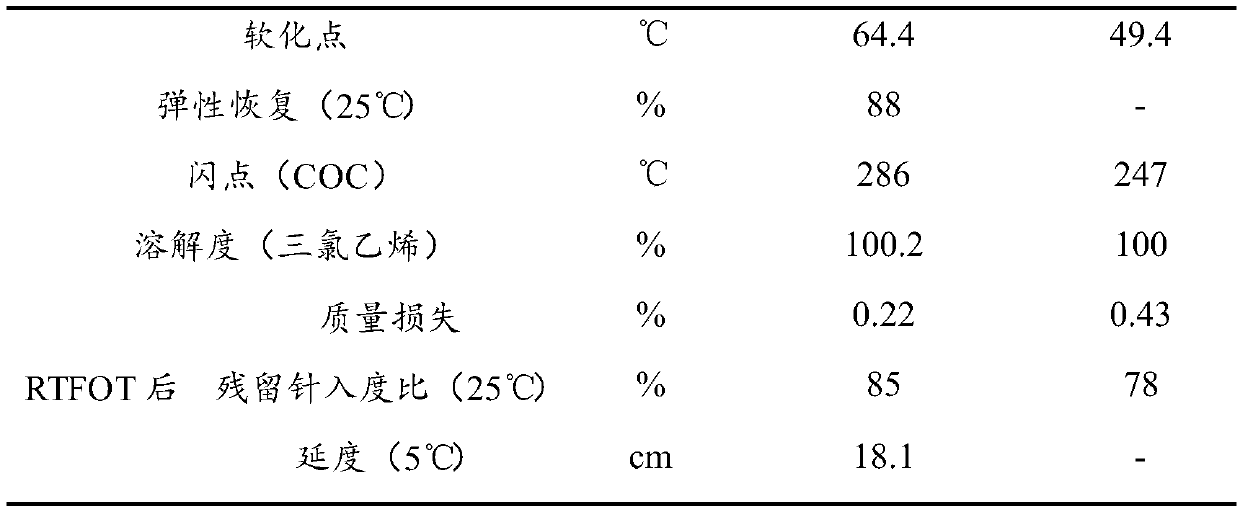

Embodiment 1

[0069] (1) 0.2kg ammonium bicarbonate is added to the water of 1kg and stirred evenly, obtains raw material mixture;

[0070] (2) 80kg of road SBS modified asphalt is heated to 170°C, and the raw material mixture obtained in step (1) is sprayed into the heated asphalt by asphalt foaming equipment to obtain foamed asphalt; the expansion ratio of the foamed asphalt 8 times;

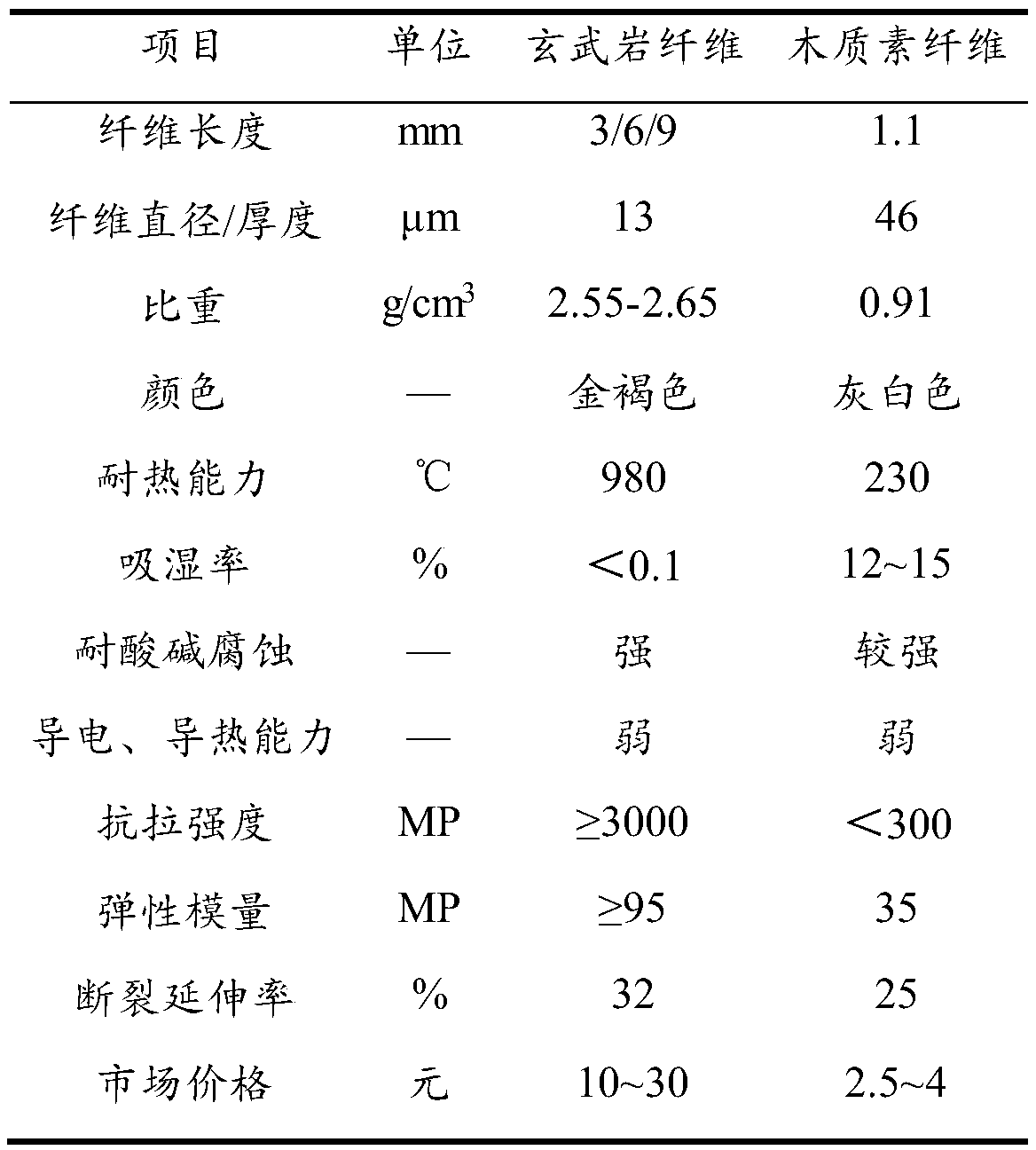

[0071] (3) The foamed asphalt obtained in step (2) and 4kg basalt fiber and 10kg calcium carbonate are added to the shearing machine, and stirred for 10s at a rotating speed of 200r / min to obtain the pavement filling material; the pavement provided by Example 1 of the present invention The joint filling material has lower viscosity and better fluidity, and can better penetrate into the depth of the crack at room temperature.

[0072] application:

[0073] Clean up the cracks on the pavement to be repaired, and use a strong blower to clean up the sundries in the cracks. If the width of the cracks is small ...

Embodiment 2

[0079] (1) 0.1kg ammonium bicarbonate is added to the water of 1kg and stirred evenly, obtains raw material mixture;

[0080] (2) 80kg No. 70 asphalt is heated to 150°C, and the raw material mixture obtained in step (1) is sprayed into the heated asphalt by asphalt foaming equipment to obtain foamed asphalt; the expansion ratio of the foamed asphalt is 11 times;

[0081] (3) Add the foamed asphalt obtained in step (2) and 3kg lignin fiber and 10kg calcium hydroxide into a shearing machine, and stir for 10s at a rotating speed of 200r / min to obtain a pavement filling material; Example 2 of the present invention provides High-quality pavement joint filling materials have low viscosity and good fluidity, and can better penetrate into the depth of cracks at room temperature.

[0082] application:

[0083] The pavement crack to be repaired is cleaned up, and the sundries in the seam are cleaned up with a powerful blower, and when the width of the seam is less (less than 3mm), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com