Method for producing arachidonic acid by fermentation of mortierella alpine

A technology of Mortierella alpine and arachidonic acid, applied in the field of microbial fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

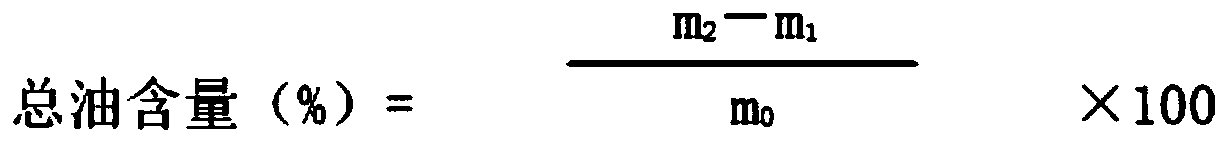

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a fermentation method for producing arachidonic acid by Mortierella alpina fermentation, wherein the fermentation medium contains untreated rapeseed meal, and the specific steps are as follows:

[0040] 1. Activation of the original strain: inoculate the Mortierella alpina strain preserved in the ampoule tube on the PDA slant medium, cultivate it at 28±1°C for 8 days, select the PDA medium plate with vigorous mycelium and spore growth, and take All the hyphae and spores on the culture medium were prepared into a spore suspension with sterile water, and the concentration of the spore suspension was not less than 10 6 cfu / mL.

[0041] 2. Seed culture: Inoculate the spore suspension in the shake flask culture medium, shake and cultivate at 28±1°C for 48 hours, and shake the shaking table at a speed of 115 rpm to obtain the seed culture solution. The shake flask culture medium The mass percentages of the main raw material components are glucose 6%,...

Embodiment 2

[0044] Embodiment 2 ferments Mortierella alpina in the same manner as in Example 1, the only difference being that the mass percentages of the main raw material components in the fermentation medium of Example 2 are glucose 8%, yeast extract 0.8%, rapeseed meal Hydrolyzate 1.5%, matrix distilled water, pH value is 7.0, wherein, the preparation method of described rapeseed meal hydrolyzate is as follows: first dilute rapeseed meal with water into a suspension with a solid-to-liquid ratio of 20%, and then at 40°C, In an environment with a pH of 7, neutral protease was added for hydrolysis. The amount of neutral protease added was 4000 U / g, hydrolyzed for 3 hours, and rapeseed meal hydrolyzate was obtained after drying.

Embodiment 3

[0046] Embodiment 3 ferments Mortierella alpina in the same manner as in Example 1, the only difference being that the mass percentages of the main raw material components in the fermentation medium of Example 3 are glucose 8%, yeast extract 0.8%, rapeseed meal Hydrolyzate 1.5%, matrix distilled water, pH value is 7.0, wherein, the preparation method of described rapeseed meal hydrolyzate is as follows: first dilute rapeseed meal with water into a suspension with a solid-to-liquid ratio of 20%, and then dilute the rapeseed meal Hydrolysis was carried out with phytase at 50° C. for 2 hours in an environment with a pH value of 5, the amount of phytase added was 10 U / g, and the rapeseed meal hydrolyzate was obtained by drying after hydrolysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com