Simple optical fiber cladding light stripping structure

A fiber cladding and simple structure technology, applied in the structure/shape of the active medium, lasers, laser components, etc., can solve the problem of limiting the power carrying capacity of cladding optical strippers, poor high temperature resistance of high-refractive-index glue, and glue Low ignition temperature and other issues, to achieve the effect of increasing the optical power that can be carried, good high temperature tolerance, and improving heat tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

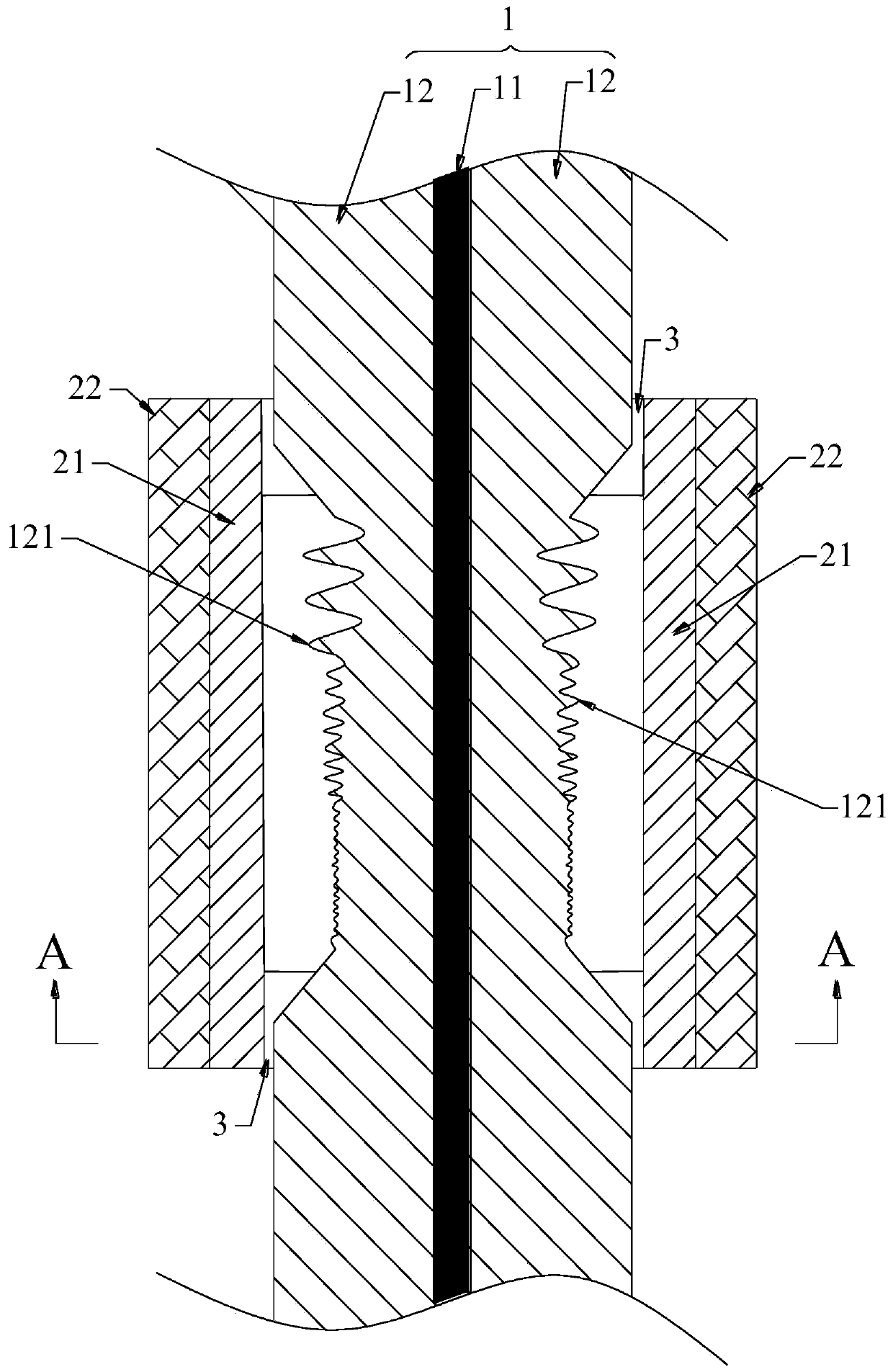

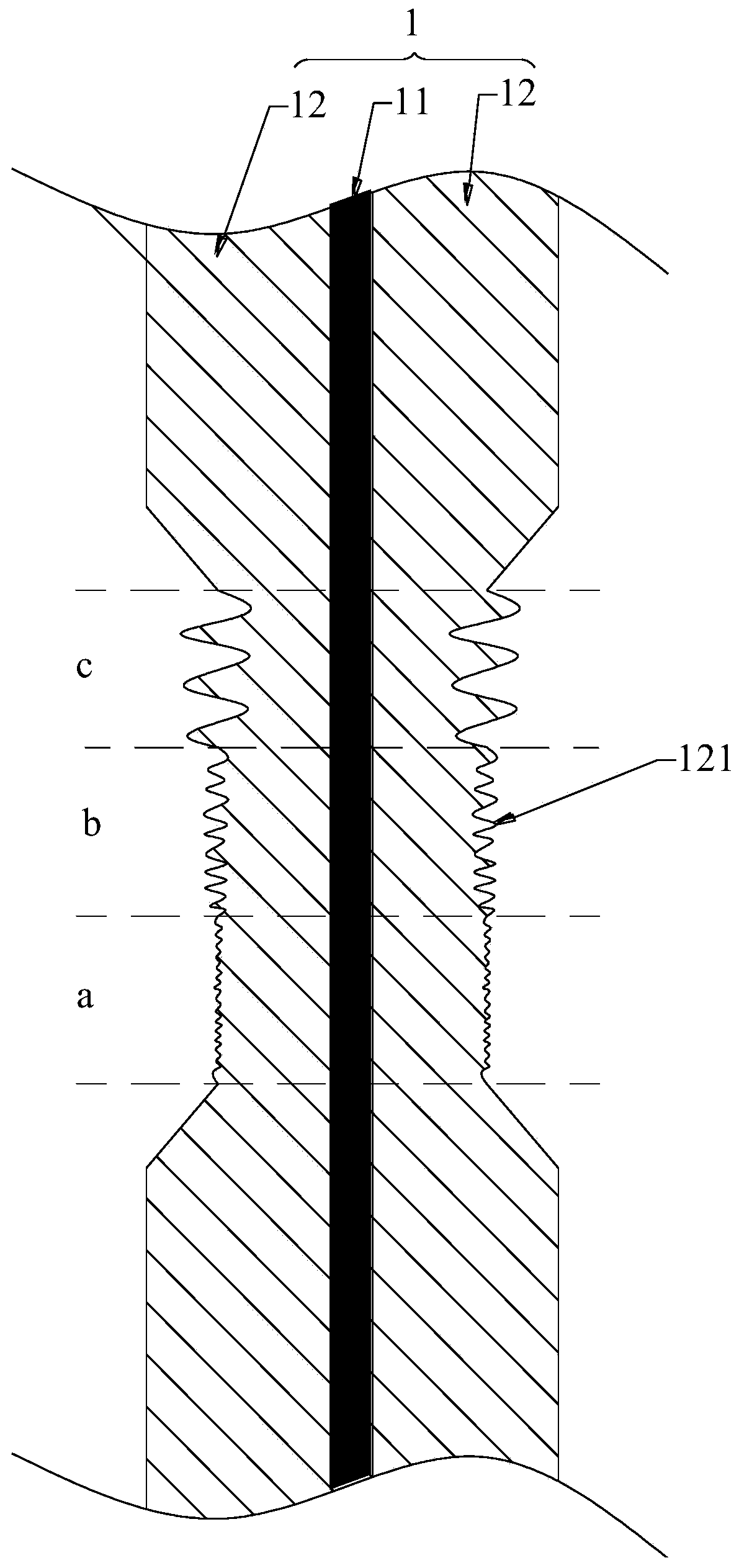

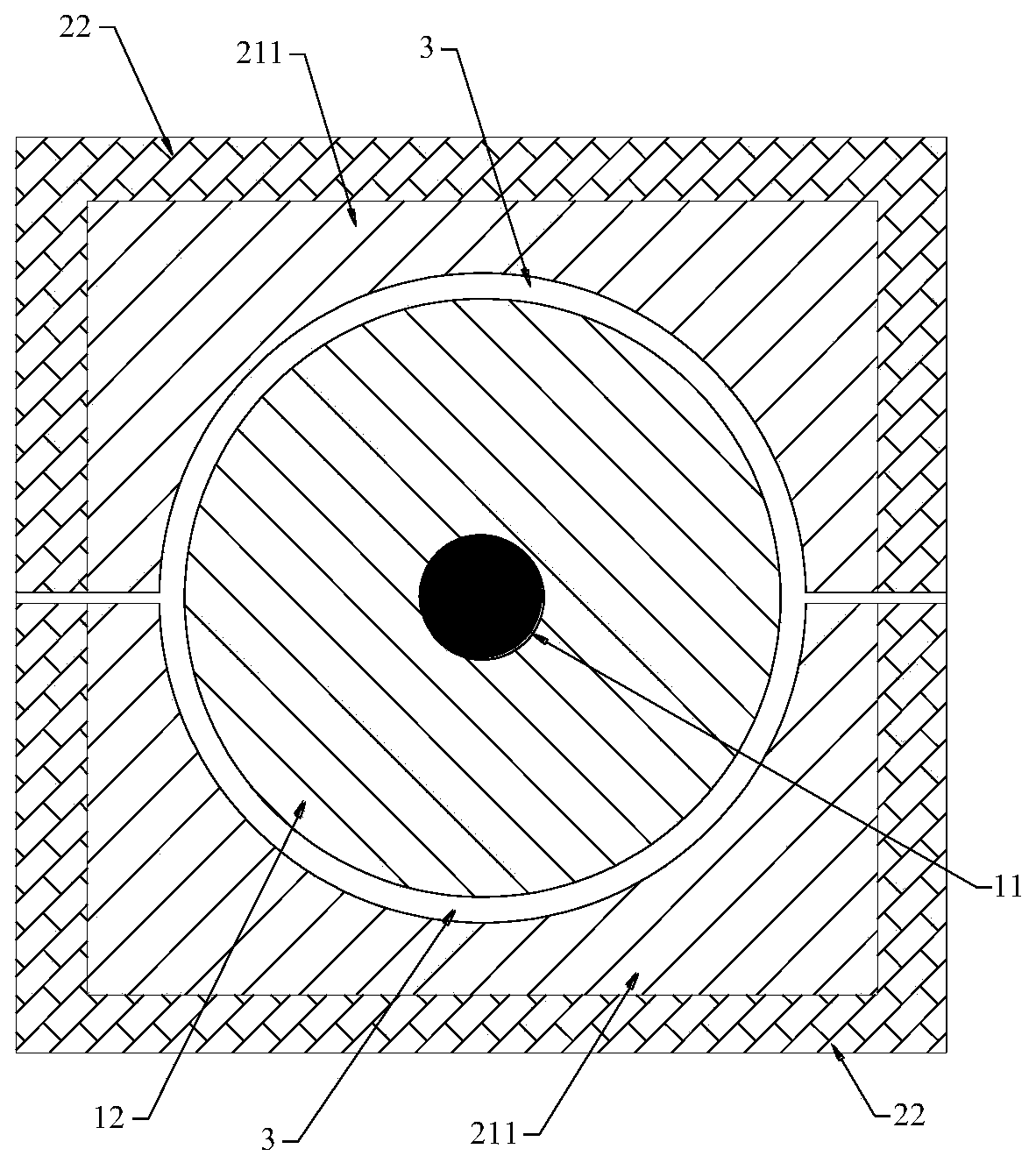

[0026] Such as figure 1 As shown, the optical fiber 1 includes a core and a cladding 12. The optical fiber cladding light stripping structure of this embodiment includes a rough scattering surface 121 and a light-transmitting heat dissipation sleeve 21. Preferably, the heat dissipation sleeve 21 is made of sapphire As a result, sapphire has good thermal conductivity and can dissipate heat quickly. The scattering surface 121 is obtained by destroying the outer surface of the cladding 12 . In this embodiment, the scattering surface 121 is preferably obtained by corroding the outer surface of the cladding 12 with hydrofluoric acid. The cooling sleeve 21 is provided with holes through the front and back (the direction from the front to the back defined herein, in figure 1 , figure 2 The middle is the direction from bottom to top), the optical fiber 1 runs through the tunn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com