Catalyst for preparing methallyl alcohol by selectivey hydrogenating methylacrolein, and preparation method thereof

A technology of methallyl alcohol and methacrolein is applied in the preparation of hydroxyl compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Low problems, to achieve the effect of reducing preparation cost, high selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

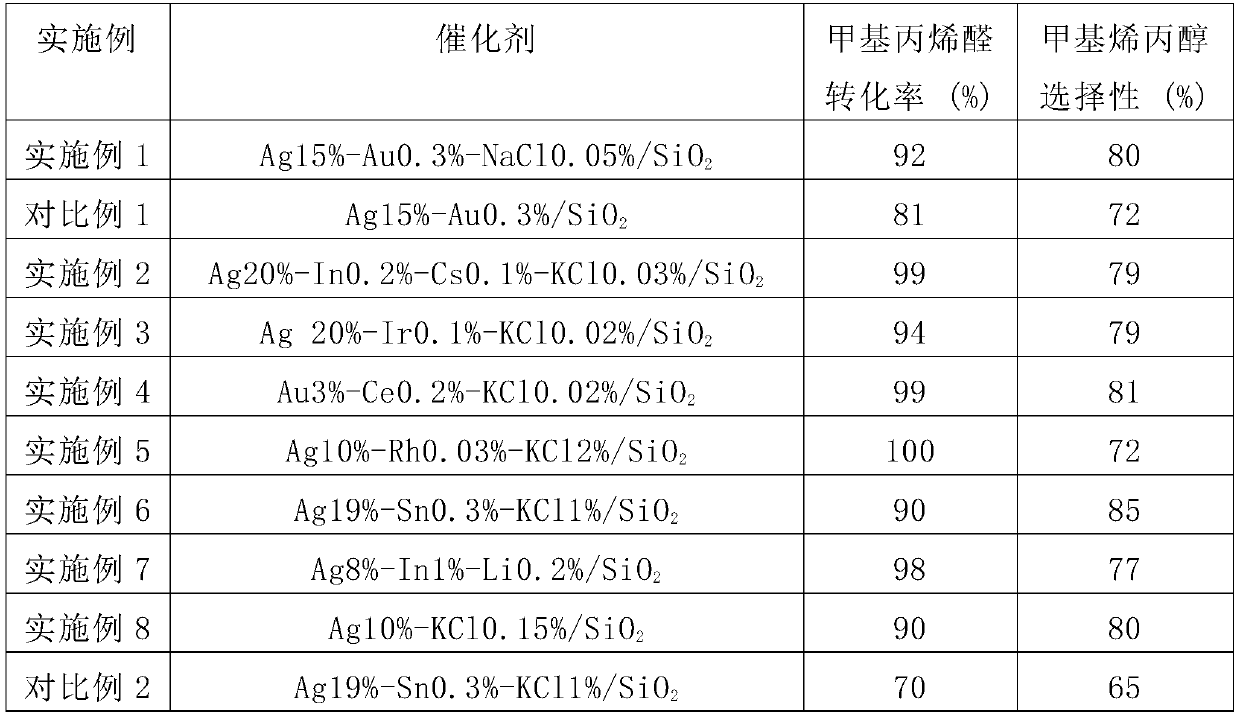

Examples

preparation example Construction

[0021] The sintered body of element X, carrier and optional element Y in the catalyst of the present invention is prepared by an in-situ one-step method, followed by adding a compound Z selected from alkali metal chloride, lithium hydroxide or a mixture thereof. Therefore, the preparation method of catalyst of the present invention comprises:

[0022] (i) Mix the precursor salt compound solution of the X element and the optional Y element with the silicon source, add the lye dropwise until the pH is not less than 6.0, such as 6.0-12.0, and keep stirring at 20-60°C for 0.5- 5 hours, then dry at 80-150°C for 4-24 hours, and bake at 250-600°C for 1-12 hours.

[0023] The precursor salt compound of X element and optional Y element suitable for the method of the present invention is not particularly limited, as long as the precursor salt compound can form an aqueous solution. In a preferred example of the present invention, the precursor salt compound is a soluble salt. In an exa...

Embodiment 1

[0046] Ag15%-Au0.3%-NaCl0.05% / SiO 2 catalyst

[0047] Configure 10 mL of silver lactate aqueous solution and 10 mL of chloroauric acid solution in proportion, add 100 g of silica sol (silicon oxide content 30%) in sequence, stir at 25°C for 0.5 hours, then drip ammonia solution, control the pH value of the mixed solution to 11, and continue The mixed solution was stirred for 3.5 hours, then dried at 100° C. for 14 hours to obtain a dried sample, and then the dried sample was calcined at 450° C. for 6 hours. The obtained calcined product was crushed and formed into 20-60 mesh particles, then added to 0.1mol / L NaCl aqueous solution and soaked in equal volume for 3 hours, then dried at 110°C for 10 hours, and calcined at 430°C for 2.5 hours to obtain a supported catalyst sample .

[0048] By weight, in the final solid sample, the Ag element in Ag accounts for 15%, the Au element in Au accounts for 0.3%, and the NaCl in NaCl accounts for 0.05% (Ag15%-Au0.3%-NaCl0.05% catalyst )...

Embodiment 2

[0053] Ag20%-In0.2%-Cs0.1%-KCl0.03% / SiO 2 catalyst

[0054] Weigh silver lactate, indium nitrate, and cesium nitrate in proportion, dissolve them in 200mL of water to form a solution, mix them with 100g of fumed silicon oxide dispersion (30% silicon oxide content), stir at 25°C for 1 hour, then drip ammonia solution to control The pH value of the mixed solution was 8, and the mixed solution was continuously stirred for 1 hour; then dried at 120° C. for 16 hours to obtain a dried sample, and then baked at 450° C. for 5 hours. The obtained calcined product was crushed and shaped into 20-60 mesh particles, then added to 0.3mol / L KCl aqueous solution and immersed for 1.5 hours, then dried at 120°C for 6 hours, and calcined at 400°C for 5 hours to obtain a supported catalyst sample.

[0055] By weight, the final solid sample contains 20% Ag element as Ag, 0.2% In element as In, 0.1% Cs element as Cs, and 0.03 KCl as KCl in the final solid sample. %.

[0056] The obtained solid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com