A method for preparing perovskite composite oxide high-entropy ceramics by hot pressing and sintering

A composite oxide and perovskite technology, applied in the field of high-entropy ceramic materials, can solve the problems of high sintering temperature, large ceramic grains and low density, and achieve large sintering driving force, small grains, and high density. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

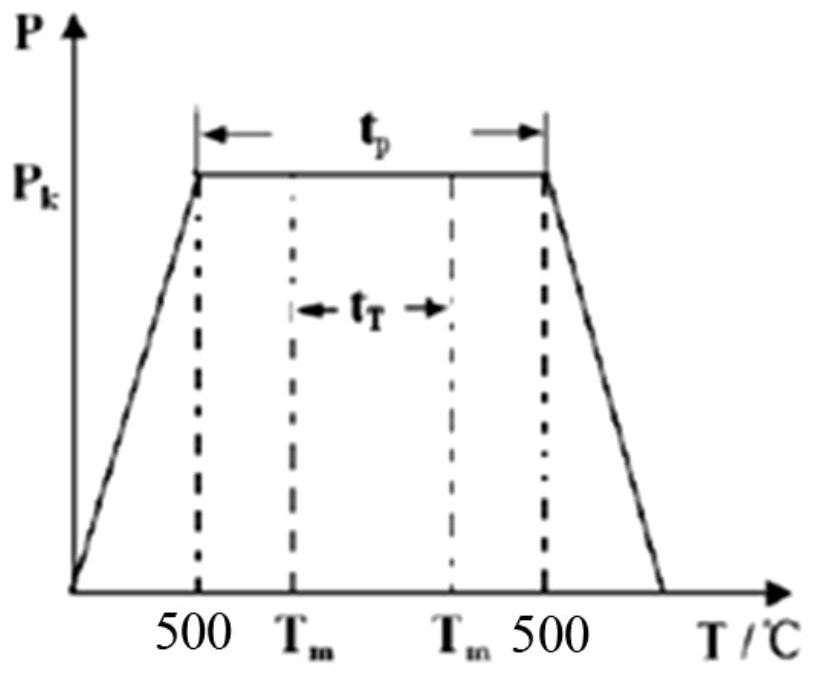

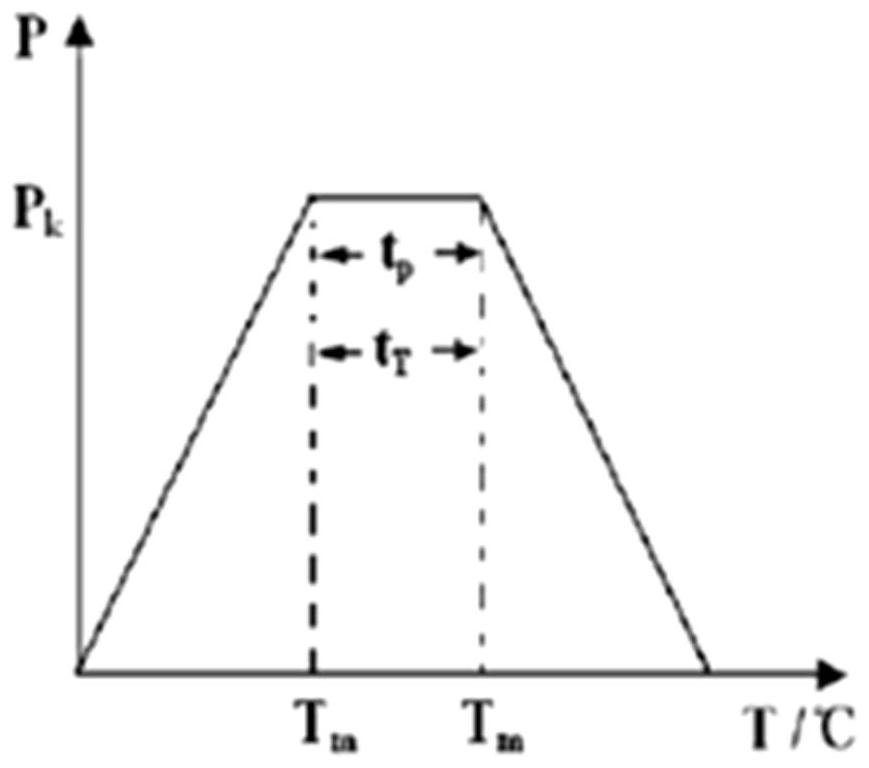

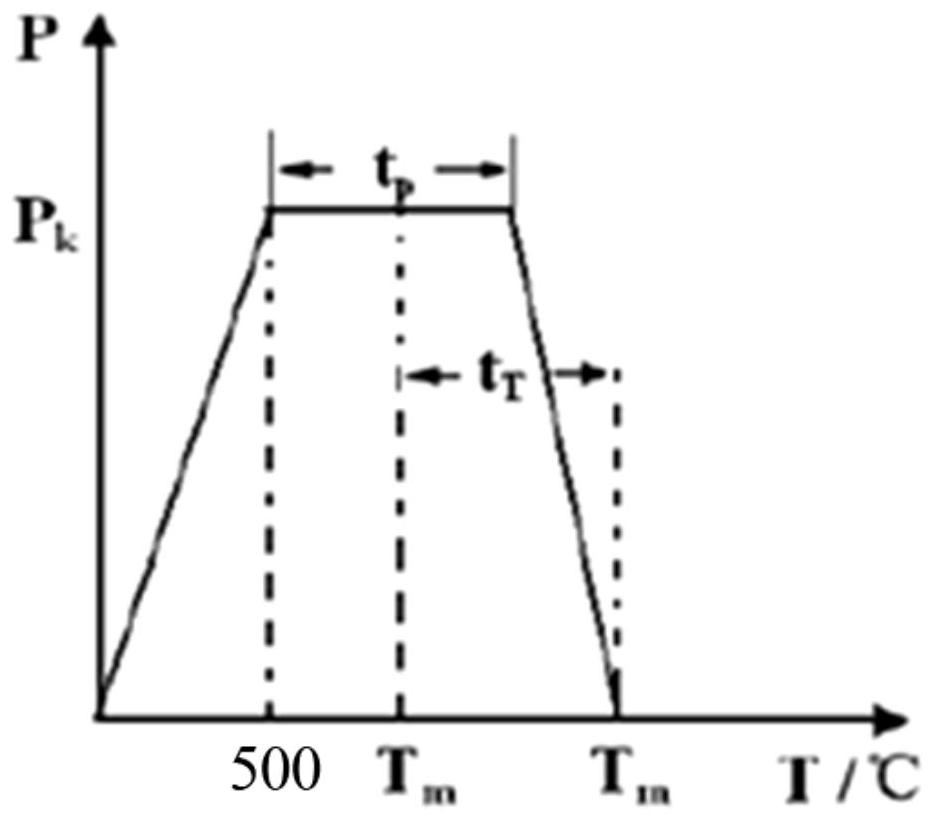

[0033] According to Sr(Zr 0.2 sn 0.2 Ti 0.2 f 0.2 Nb 0.2 )O 3According to the stoichiometric ratio of the total amount of 40g, strontium carbonate and other metal oxides were weighed respectively, and added to the nylon tank; with absolute ethanol as the ball milling medium, mixed and ball milled on the planetary ball mill for 36 hours, every ball milled for 30 minutes, and stopped for 10 minutes. Minutes; dry at 100°C to obtain the raw material precursor; pre-fire the raw material precursor at 1000°C for 2 hours, grind, pass through a 200-mesh sieve, put it into a high-strength graphite mold, put it into a hot-press furnace, and vacuumize the furnace Internal vacuum reaches 10 -2 Pa; start to heat up from room temperature at a rate of 20°C / min. When the furnace temperature rises to 500°C, the loaded pressure reaches 15MPa; the sintering temperature is 1250°C, and the holding time is 120 minutes; when the holding time reaches 90 minutes, start Decrease the pressure at a ...

Embodiment 2

[0035] According to Sr(Zr 0.2 sn 0.2 Ti 0.2 f 0.2 Tb 0.2 )O 3 According to the stoichiometric ratio of the total amount of 40g, strontium carbonate and other metal oxides were weighed respectively, and added to the nylon tank; with absolute ethanol as the ball milling medium, mixed and ball milled on the planetary ball mill for 36 hours, every ball milled for 30 minutes, and stopped for 10 minutes. Minutes; dry at 100°C to obtain the raw material precursor; pre-fire the raw material precursor at 1000°C for 2 hours, grind, pass through a 200-mesh sieve, put it into a high-strength graphite mold, put it into a hot-press furnace, and vacuumize the furnace Internal vacuum reaches 10 -2 Pa; start to heat up from room temperature at a rate of 20°C / min, and when the furnace temperature rises to 500°C, the loaded pressure reaches 15MPa; the sintering temperature is 1200°C, and the holding time is 120 minutes; when the holding time reaches 90 minutes, start Decrease the pressure ...

Embodiment 3

[0037] According to Sr(Zr 0.2 sn 0.2 Ti 0.2 f 0.2 Ta 0.2 )O 3 According to the stoichiometric ratio of the total amount of 40g, strontium carbonate and other metal oxides were weighed respectively, and added to the nylon tank; with absolute ethanol as the ball milling medium, mixed and ball milled on the planetary ball mill for 36 hours, every ball milled for 30 minutes, and stopped for 10 minutes. Minutes; dry at 100°C to obtain the raw material precursor; pre-fire the raw material precursor at 1000°C for 2 hours, grind, pass through a 200-mesh sieve, put it into a high-strength graphite mold, put it into a hot-press furnace, and vacuumize the furnace Internal vacuum reaches 10 -2 Pa; start to heat up from room temperature at a rate of 20°C / min, and when the furnace temperature rises to 500°C, the loaded pressure reaches 15MPa; the sintering temperature is 1200°C, and the holding time is 120 minutes; when the holding time reaches 90 minutes, start The pressure was reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com