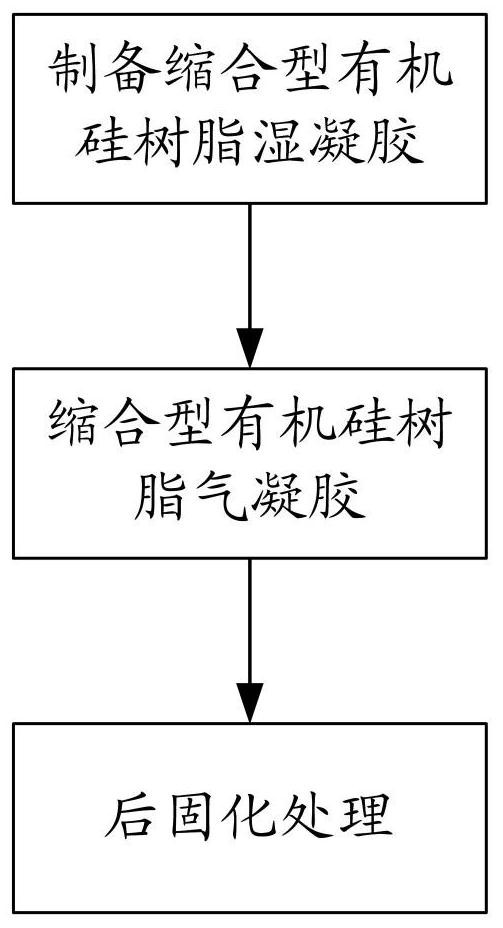

A kind of condensation type silicone resin airgel and preparation method thereof

An organosilicon and condensation-type technology, which is applied in the field of condensation-type silicone resin aerogel and its preparation, can solve the problems that the condensation-type silicone resin aerogel cannot be prepared, the active group is far away, and the degree of hydroxyl reaction is high. , to achieve the effect of low overall cost, realization of cross-linking degree, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Dissolve 200g Dowsil RSN 0806 (the solid content of the product itself is 50%, the solvent is a mixed solvent of toluene and xylene), 5g ethyl orthosilicate and 0.6g dibutyltin dilaurate in 800g ethyl acetate, stir at room temperature for 30min, pour It was left standing in the mold, and after the reaction system gelled, it was aged at room temperature for 24 hours to obtain a condensation-type silicone resin wet gel.

[0045] 2. Perform solvent replacement on the condensed silicone resin wet gel obtained in step 1, soak it with cyclohexane for 3 times, and then carry out supercritical CO 2 Drying, drying at 40° C. and 15 MPa for 8 h to obtain a condensation-type silicone resin aerogel.

[0046] 3. Post-curing the aerogel prepared in step 2, and the treatment conditions are 60°C for 1 hour, 80°C for 1 hour, 100°C for 1 hour, and 120°C for 1 hour.

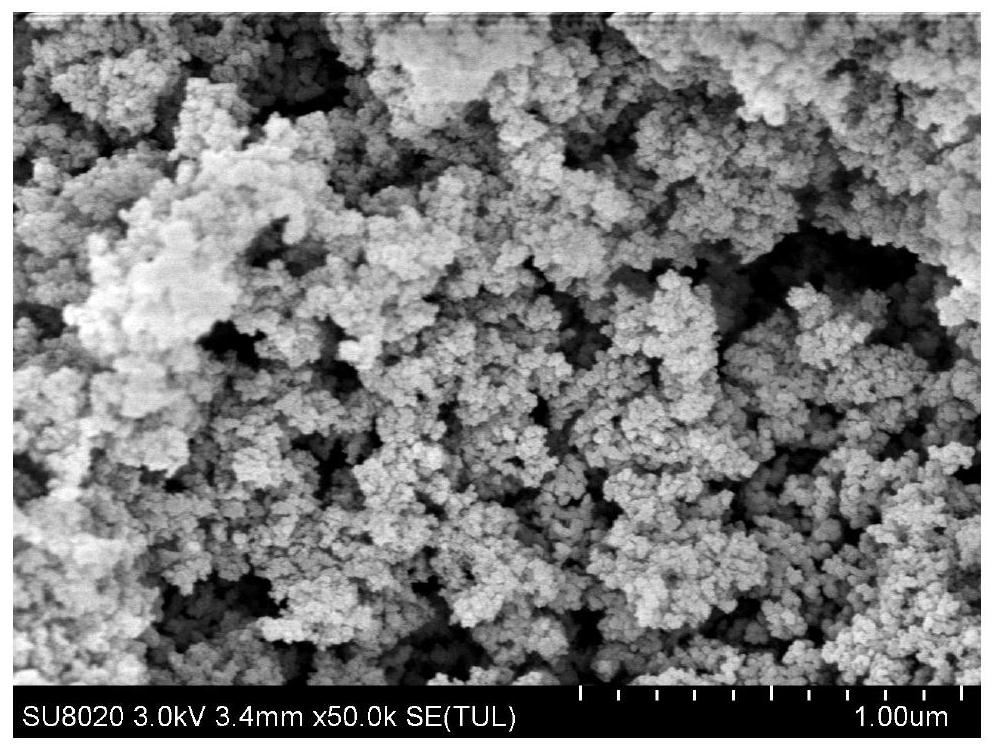

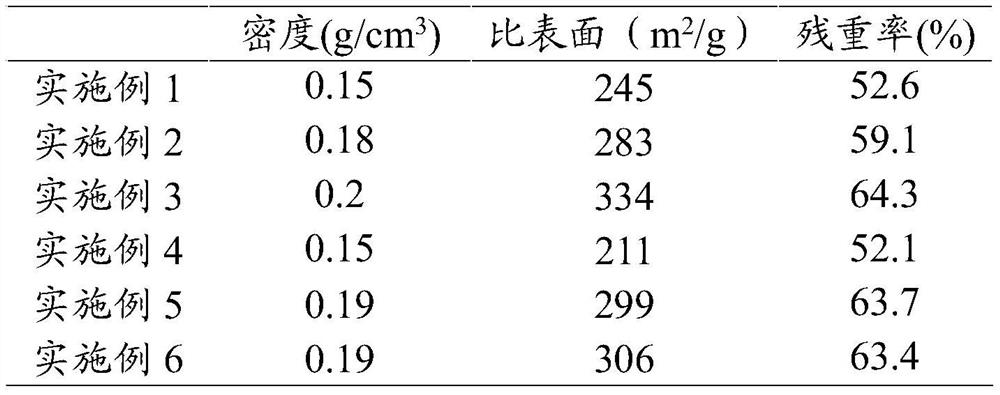

[0047] The density of the condensation-type silicone resin aerogel obtained in this example is 0.15 g / cm 2 , see attac...

Embodiment 2

[0050] The preparation conditions and process of the condensation-type silicone resin aerogel are the same as those in Example 1, except that the mass of the added ethyl orthosilicate is 20 g, and the density of the aerogel is 0.18 g / cm 2 .

Embodiment 3

[0052] Except that the mass of ethyl orthosilicate added is 30g, the preparation conditions and process of condensation type silicone resin aerogel are the same as those in Example 1, and the density of aerogel is 0.2g / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com