Impregnated aramid rubber-based special material and preparation method thereof

A special material, aramid technology, applied in fiber types, textiles and papermaking, fiber processing, etc., can solve the problems of poor mechanical strength and poor wear resistance, achieve good wear resistance, improve wear resistance and mechanical strength , Improve the effect of smooth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

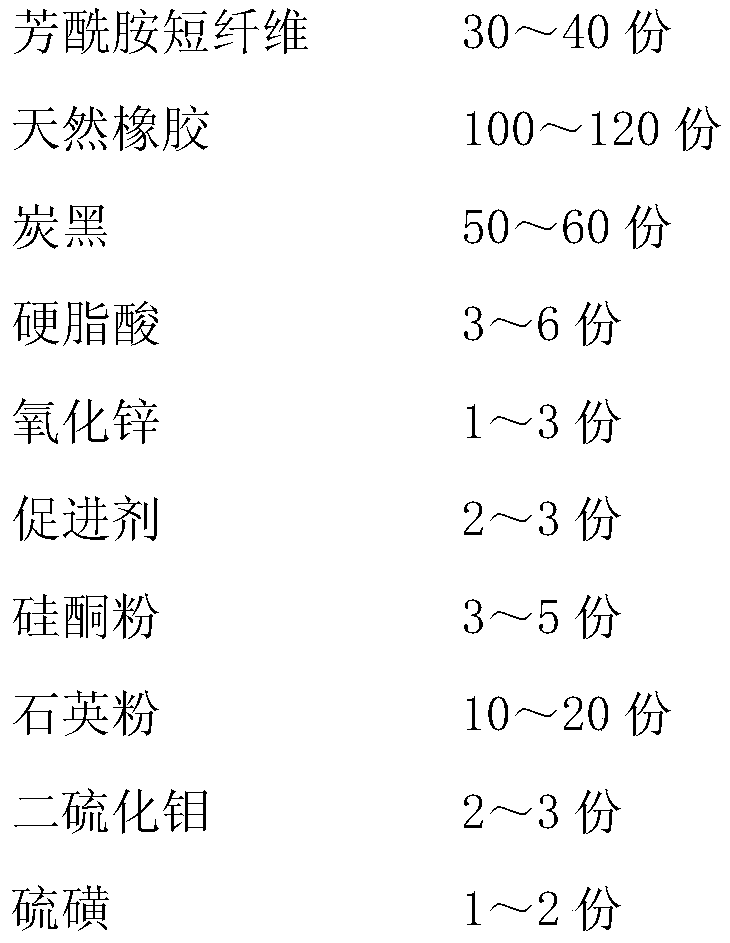

[0039] Example 1 discloses an impregnated aramid rubber-based specialty material, including raw aramid short fibers, natural rubber, carbon black, stearic acid, zinc oxide, accelerators, silicone powder, quartz powder, molybdenum disulfide and sulfur , the weight components of aramid staple fiber, natural rubber, carbon black, stearic acid, zinc oxide, accelerator, silicone powder, quartz powder, molybdenum disulfide and sulfur are:

[0040]

[0041] The length of the aramid short fiber is 2mm. When the length of the aramid fiber is too short, the effect of reinforcing the composite material cannot be achieved. When the length of the aramid fiber is too long, the fiber will be exposed. The accelerator is the accelerator NS .

[0042] This embodiment also discloses a preparation method for impregnating aramid rubber-based special materials, which includes the following preparation steps:

[0043] Step 1: shearing, using a fiber shearing machine to shear the aramid fiber to ...

Embodiment 2

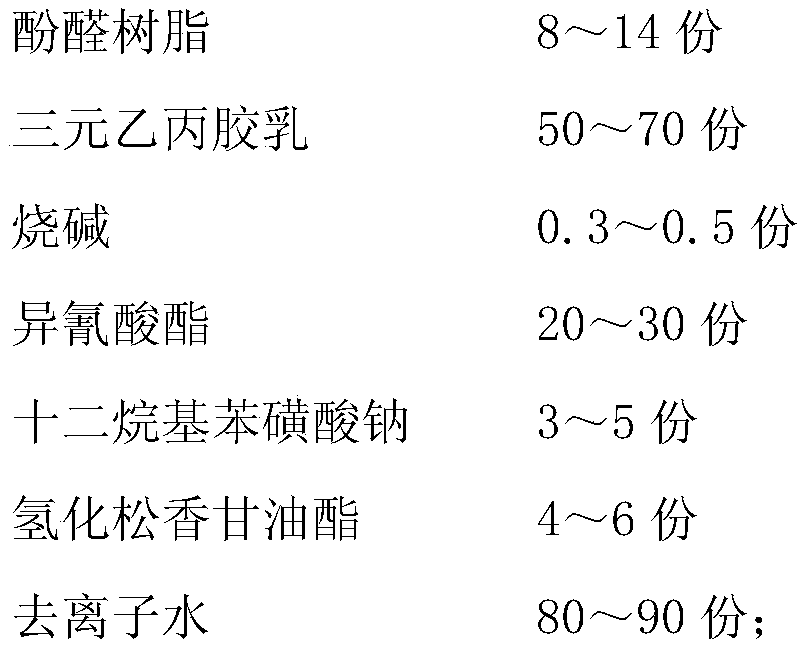

[0064] Example 2 discloses an impregnated aramid rubber-based specialty material, including raw aramid short fibers, natural rubber, carbon black, stearic acid, zinc oxide, accelerators, silicone powder, quartz powder, molybdenum disulfide and sulfur , the weight components of aramid staple fiber, natural rubber, carbon black, stearic acid, zinc oxide, accelerator, silicone powder, quartz powder, molybdenum disulfide and sulfur are:

[0065]

[0066] The length of the aramid short fiber is 2mm. When the length of the aramid fiber is too short, the effect of reinforcing the composite material cannot be achieved. When the length of the aramid fiber is too long, the fiber will be exposed. The accelerator is accelerator PZ .

[0067] This embodiment also discloses a preparation method for impregnating aramid rubber-based special materials, which includes the following preparation steps:

[0068] Step 1: shearing, using a fiber shearing machine to shear the aramid fiber to obta...

Embodiment 3

[0089] Example 3 discloses an impregnated aramid rubber-based special material, including raw aramid short fiber, natural rubber, carbon black, stearic acid, zinc oxide, accelerator, silicone powder, quartz powder, molybdenum disulfide and sulfur , the weight components of aramid staple fiber, natural rubber, carbon black, stearic acid, zinc oxide, accelerator, silicone powder, quartz powder, molybdenum disulfide and sulfur are:

[0090]

[0091] The length of the aramid short fiber is 3mm. When the length of the aramid fiber is too short, the effect of reinforcing the composite material cannot be achieved. When the length of the aramid fiber is too long, the fiber will be exposed. The accelerator is accelerator PX .

[0092] This embodiment also discloses a preparation method for impregnating aramid rubber-based special materials, which includes the following preparation steps:

[0093] Step 1: shearing, using a fiber shearing machine to shear the aramid fiber to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com